Maintaining method of internal leakage low-pressure bypass valve of valve body

A bypass valve, low pressure technology, applied in the field of maintenance of leaky valves in the valve body, can solve the problems of inconvenient disassembly and replacement, affecting the thermal efficiency of the unit operation safety, and achieve the effect of solving the mechanical zero position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

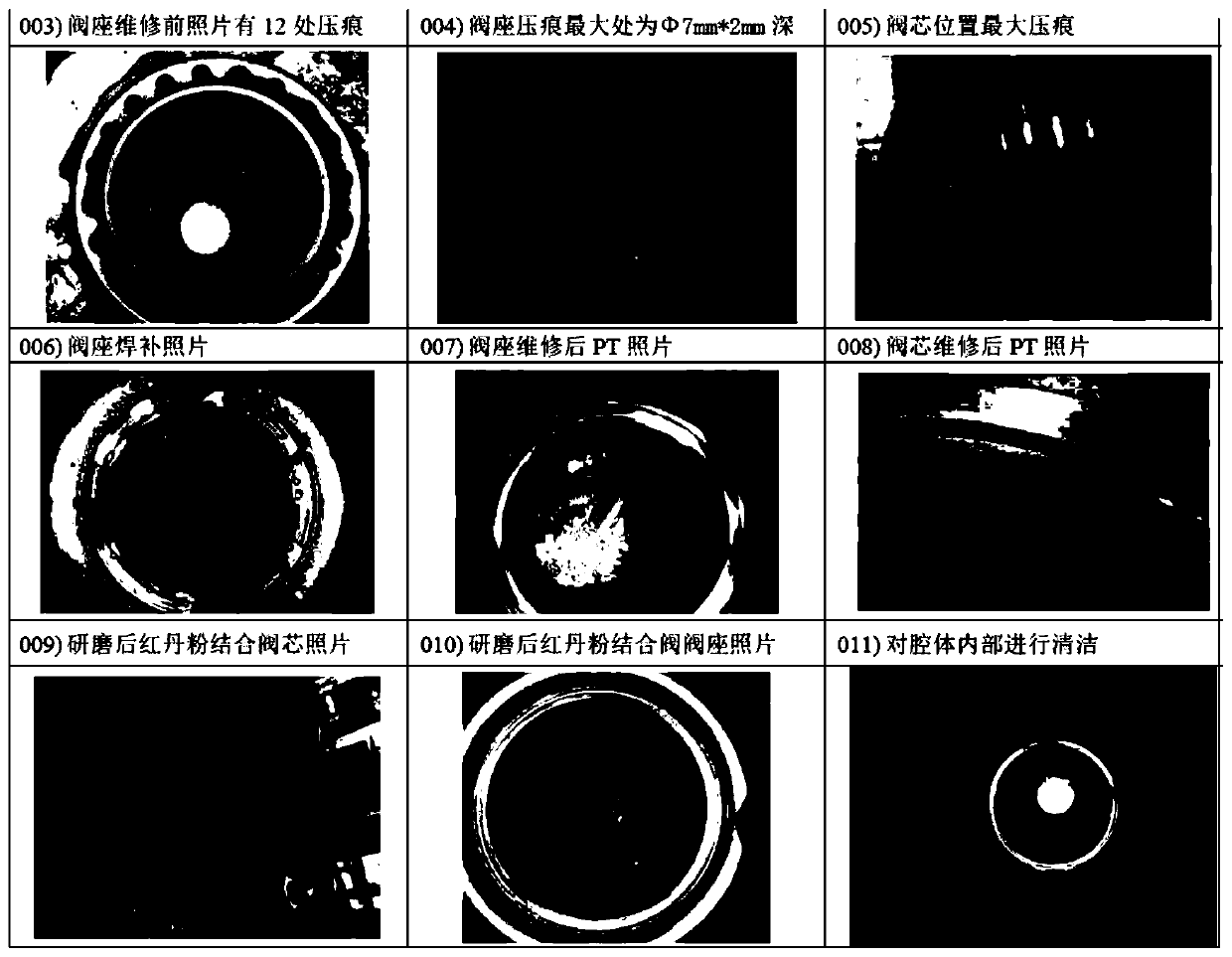

[0019] The present invention provides a maintenance method for a low-pressure bypass valve with internal leakage of the valve, taking the maintenance of the internal leakage of the low-pressure bypass valve of the 2# unit of a company in Shaanxi as an example:

[0020] The valve body of the low-pressure bypass valve has only been used for one year. Before maintenance, the valve leaked inside; the sealing surface was severely damaged, and the maximum indentation was 2mm deep and 7mm in diameter.

[0021] The valve seat is welded to the valve body and cannot be disassembled. The specific reason is speculated that the tightness of the valve sealing surface is not enough, and there may be a phenomenon that the mechanical zero position and the thermal zero position overlap, or the internal leakage of the valve caused by the insufficient tightening force of the valve sealing surface that occurs after the thermal zero position is determined.

[0022] The applicant formulates a repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com