Cylindrical battery roll core and manufacturing method thereof

A technology of cylindrical battery and manufacturing method, which is applied in the direction of secondary battery manufacturing, cylindrical shell battery/battery, secondary battery, etc., which can solve the problems of short circuit in the battery core and non-winding of tabs, etc., and reduce equipment and environment. Requirements, design solutions, novel effects of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

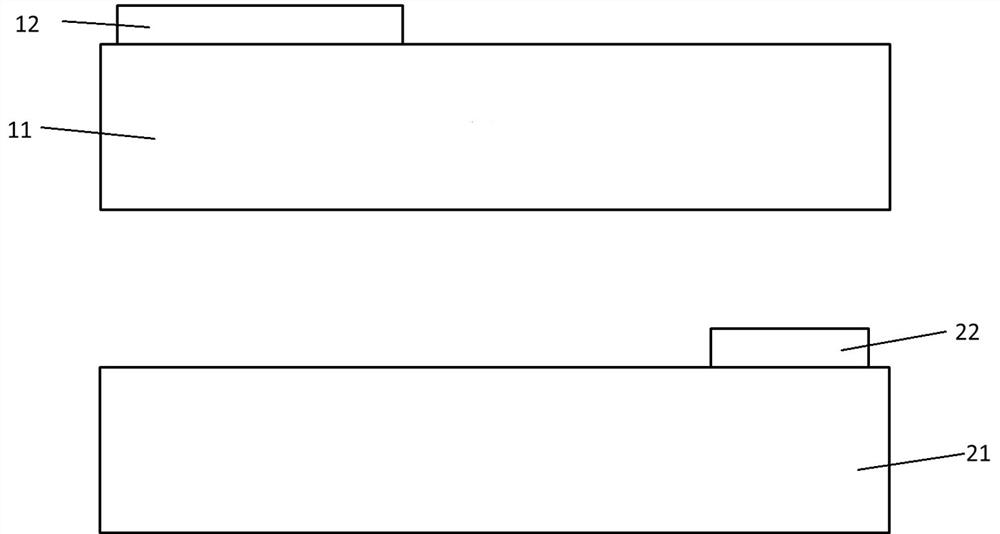

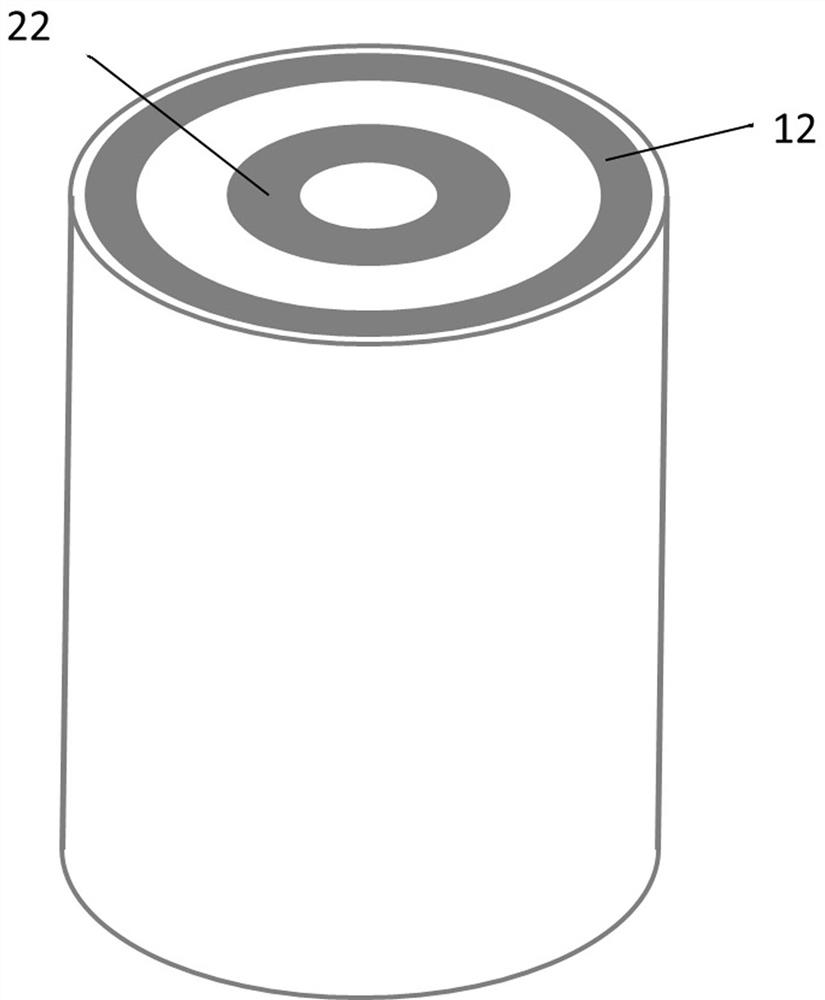

[0026] see figure 2 Shown is a schematic diagram of the overall structure of the cylindrical battery core of this embodiment, which is composed of a positive electrode sheet 11 , a separator, a negative electrode sheet 21 and a separator that are stacked and wound.

[0027] The battery pole piece is continuously coated, the coated area is used as the active material area, and the non-coated area is used as the tab. After the coating is completed, the pole piece is rolled to reach the designed compaction density. Subsequent sectioning into strips to form figure 1 The positive electrode sheet 11 and the negative electrode sheet 21 shown in , wherein the large rectangle is the coating area of the positive electrode sheet 11, 12 is the positive electrode ear, and the positive electrode ear 12 is the remaining electrode ear after part of the electrode ear has been cut off; the negative electrode sheet 21 The middle and large rectangle is the coated area of the negative elect...

Embodiment 2

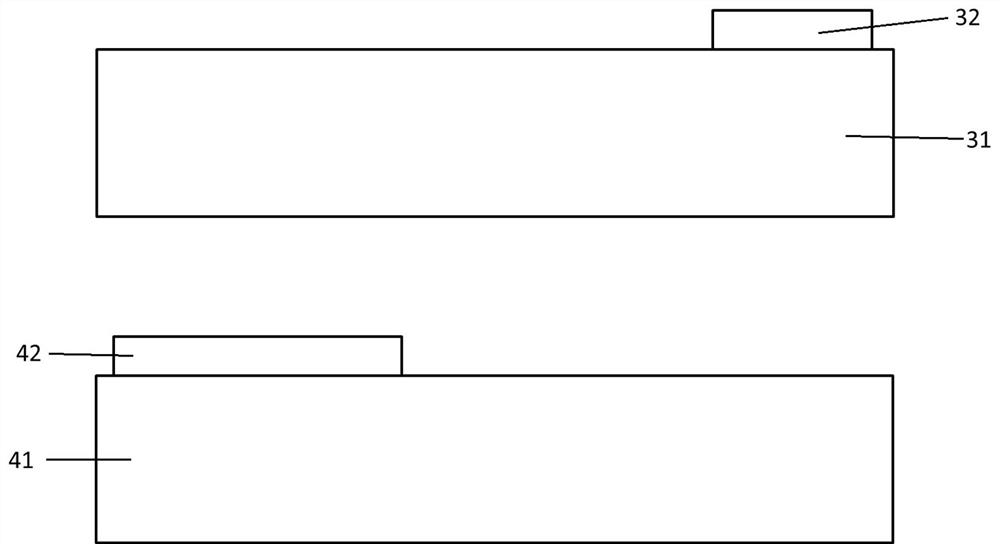

[0036] see Figure 4 Shown is a schematic diagram of the overall structure of the cylindrical battery core of this embodiment, which is composed of a positive electrode sheet 31 , a separator, a negative electrode sheet 41 and a separator that are stacked and wound.

[0037] The battery pole piece is continuously coated, the coated area is used as the active material area, and the non-coated area is used as the tab. After the coating is completed, the pole piece is rolled to reach the designed compaction density. Subsequent sectioning into strips to form image 3 The positive electrode sheet 31 and the negative electrode sheet 41 shown in , wherein the large rectangle is the coating area of the positive electrode sheet 31, 32 is the positive electrode ear, and the positive electrode ear 32 is the remaining electrode ear after part of the electrode ear has been cut off; the negative electrode sheet 41 The middle and large rectangle is the coated area of the negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com