Drill carriage actuator and anchor rod drill carriage

An actuating mechanism and a technology for a rock bolt drilling rig, which can be used in the installation of rock bolts, rotary drilling rigs, and earth-moving drilling, etc., and can solve problems such as low positioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

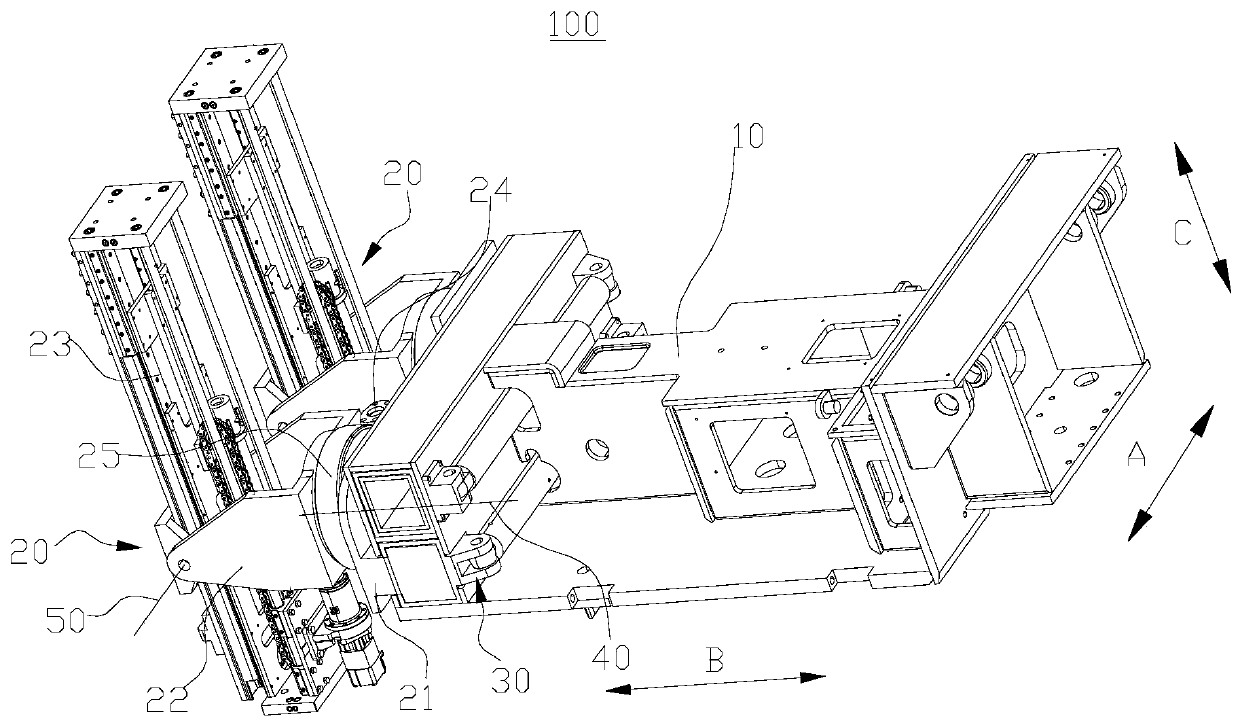

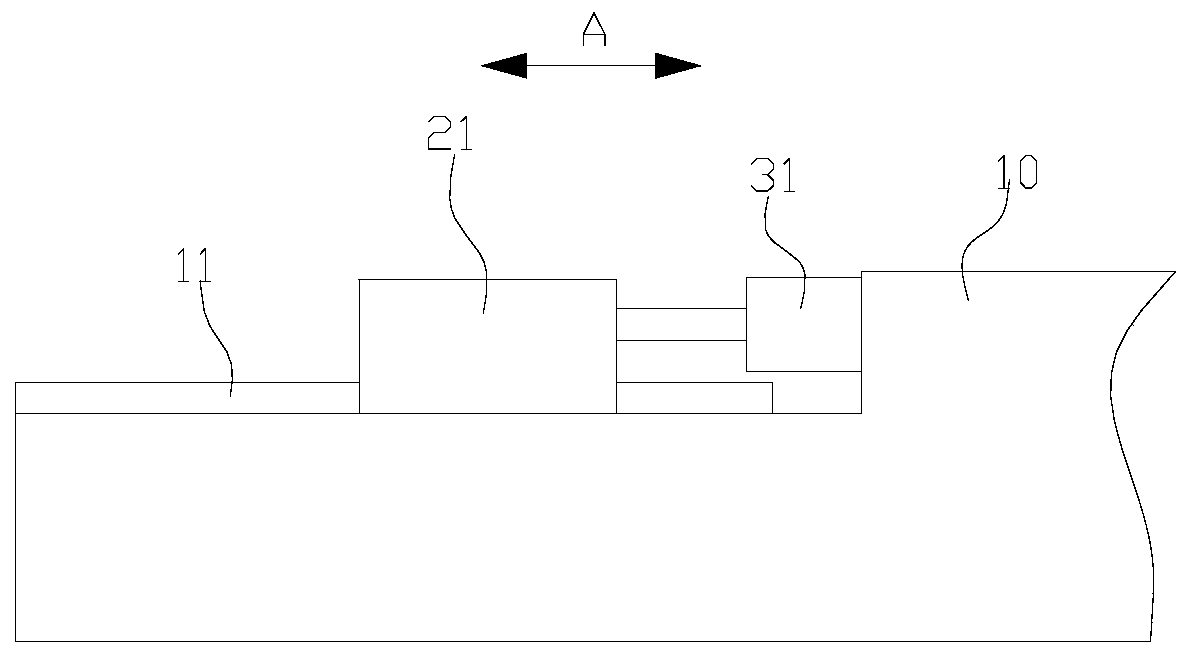

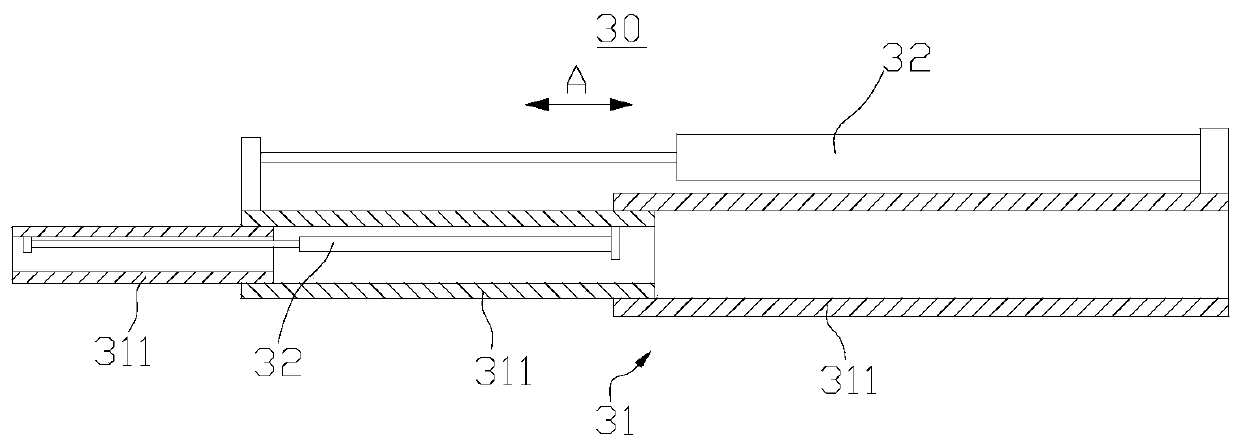

[0072] Such as figure 1 As shown, this embodiment provides a drill rig actuator 100, which includes a base 10, an actuator 20, and a driving mechanism 30.

[0073] The base 10 is configured to interact with the walking device ( figure 1 Not shown) connection, the walking device has a transverse direction A, a longitudinal direction B and a vertical direction C, and the walking direction of the walking device is the longitudinal direction B.

[0074] It is understandable that when the walking device is placed in a horizontal plane, the transverse direction A and the longitudinal direction B are two directions perpendicular to each other in the horizontal plane, and the vertical direction C is the direction perpendicular to the horizontal plane. Of course, the drill rig actuator 100 also has a transverse direction A, a longitudinal direction B, and a vertical direction C. After the base 10 of the drill rig actuator 100 is connected to the traveling device, the transverse direction A o...

Embodiment 2

[0106] Such as Picture 10 As shown, this embodiment provides a bolting rig 200, which includes a traveling device 210 and the drill rig actuator 100 in the above embodiment, and the base 10 is connected to the traveling device 210.

[0107] Optionally, the walking device 210 includes a chassis 211 and a crawler walking mechanism 212 provided at the bottom of the chassis 211, and the walking device 210 is implemented by the crawler walking mechanism 212.

[0108] The walking device 210 has a horizontal direction A, a vertical direction B, and a vertical direction C, and the walking direction of the walking device 210 is the vertical direction B.

[0109] It is understandable that when the walking device 210 is placed in a horizontal plane, the horizontal direction A and the vertical direction B are two directions perpendicular to each other in the horizontal plane, and the vertical direction C is a direction perpendicular to the horizontal plane. The transverse direction A of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com