Gear shifting method of rotary knob lifting type electronic wire control gear shifter

A shift method and electronic wire technology, which are applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve the shift lever structure shifter arrangement, design and shift handle shape and arrangement And the complex structure design, large cockpit space, affecting the appearance and other problems, to achieve the effect of light weight, strong reliability, improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

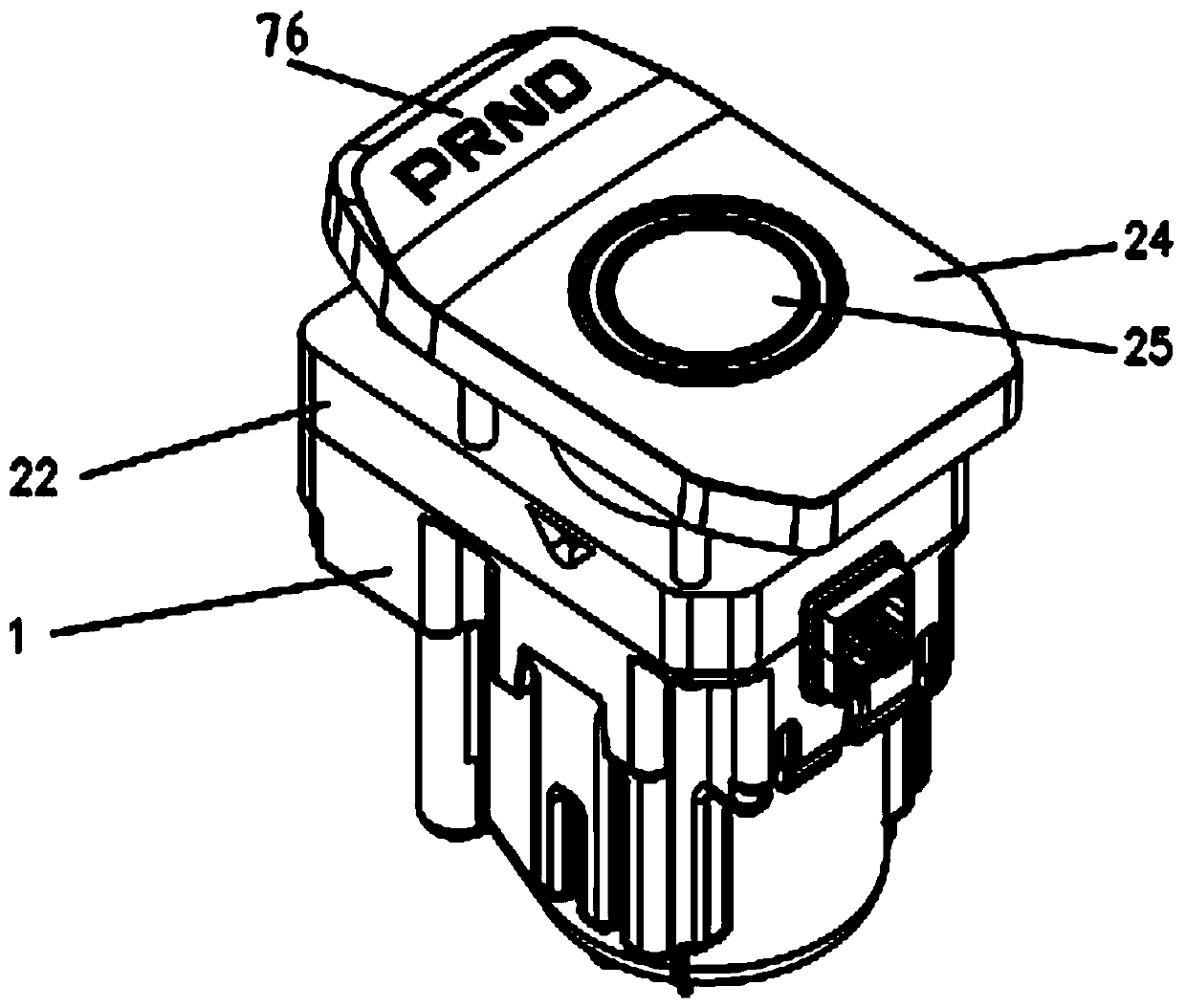

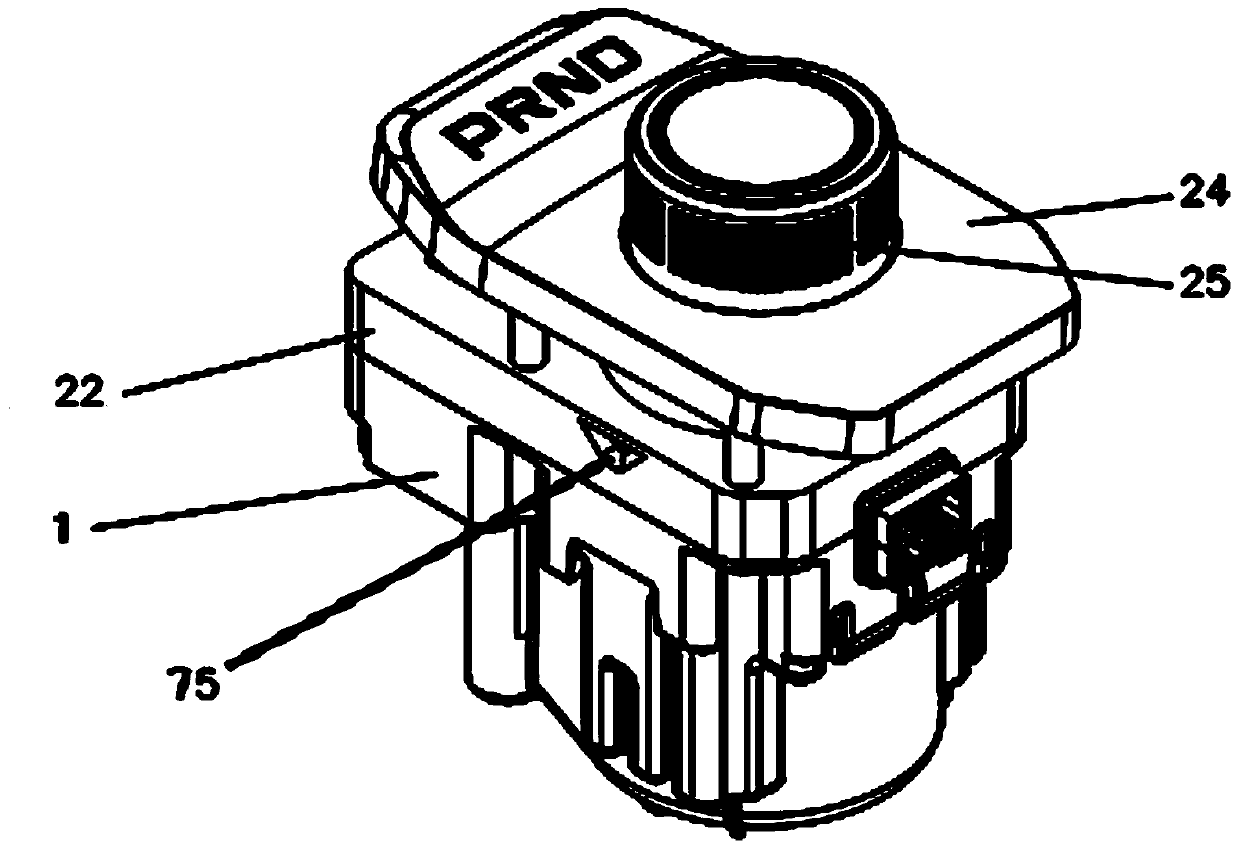

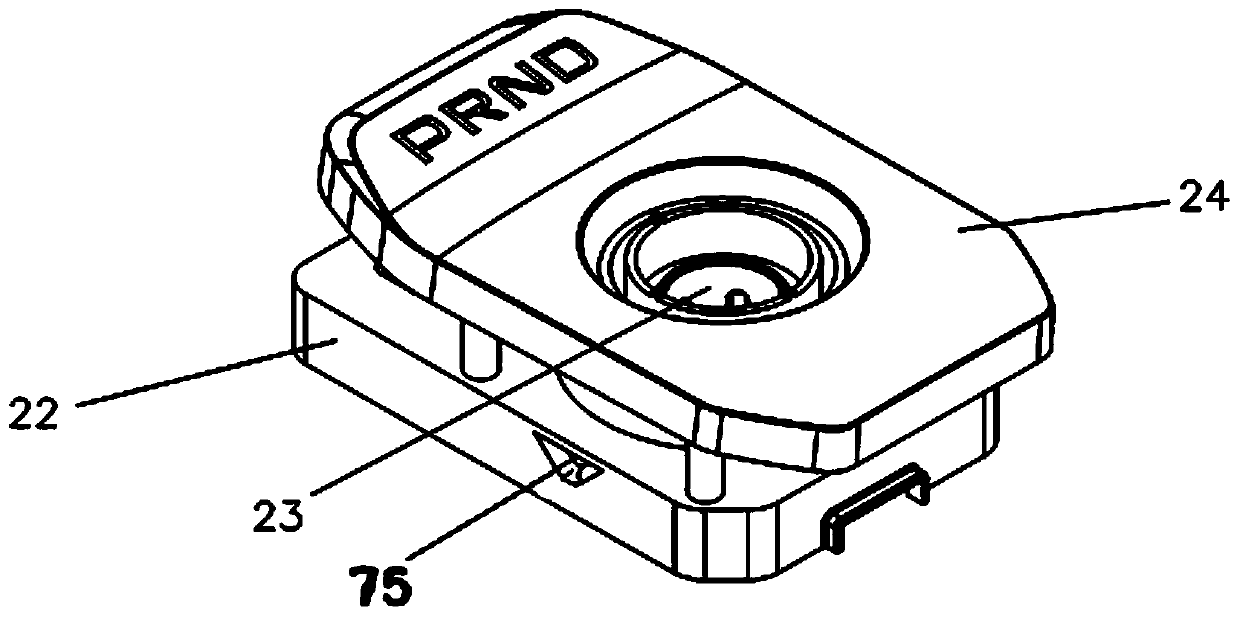

[0048] Attached below Figure 1-12 The present invention is described in further detail.

[0049] During specific implementation: a method for shifting gears of a knob lift type electronic shifter by wire, comprising the following steps:

[0050] S1: The car starts, the shift knob rises, and the shift knob is in a steady state gear;

[0051] S2: Turn the shift knob to the left or right for one or two strokes, and the gear position signal is transmitted to the MCU module for identification, and the shift knob is reset to the steady-state gear position;

[0052] S3: When it is necessary to shift gears, brake, and then repeat the above step S2;

[0053] S4: The car is turned off, and the shift knob falls.

[0054] When the method is used, the gear shift knob can be raised or lowered, and the space is more reasonably utilized. During the driving process, after the MCU module recognizes the gear position, even if the shift knob is rotated by mistake, the gear position will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com