A sound source control valve for an automatic liquid level measurement device for high-pressure gas wells

An automatic measurement and high-pressure gas technology, which is applied in the direction of valve devices, valve lifts, engine components, etc., can solve problems such as sound source control valve failure, high electromagnetic suction, and sound source control valve failure to trigger, so as to solve the problems of failure to reset and reduce Effect of Spring Preload Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

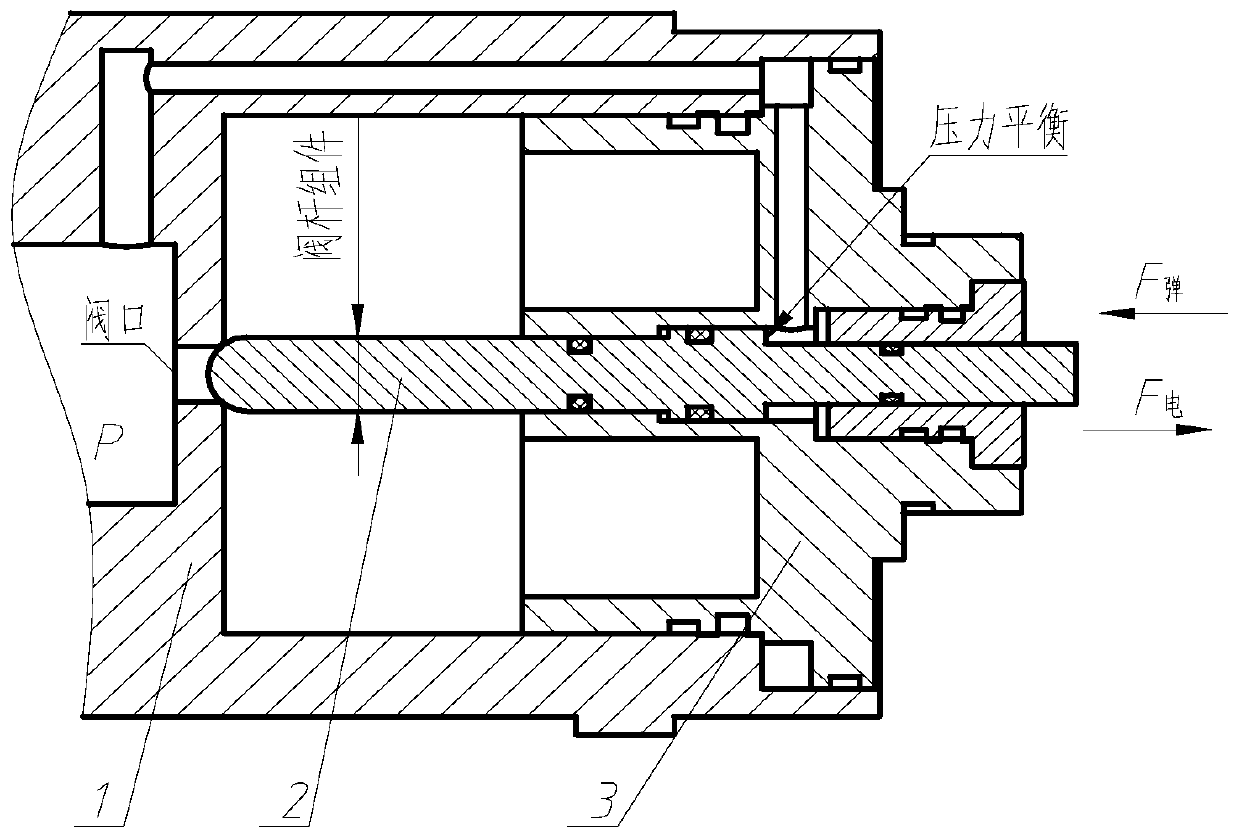

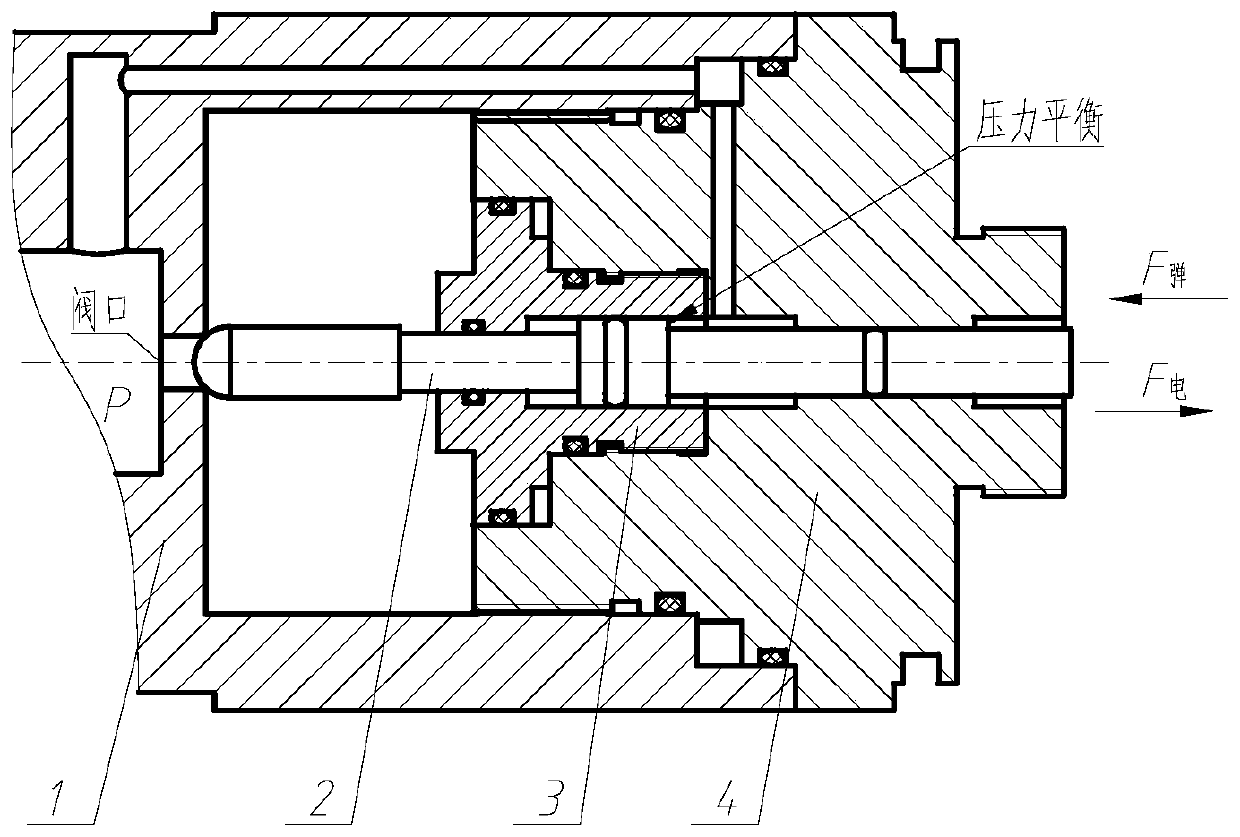

Embodiment 1

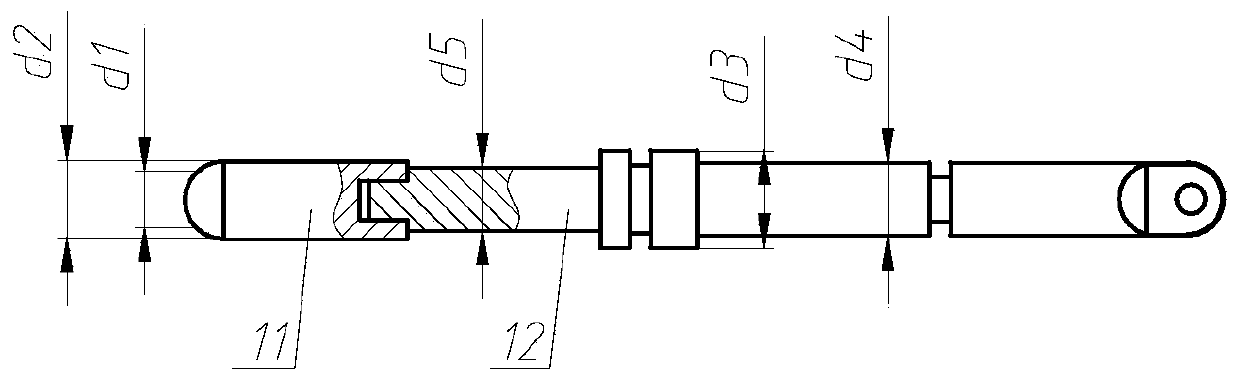

[0026] see figure 2 , the valve stem assembly 2 of the present invention is as image 3 As shown, it is composed of a valve core 11 and a valve stem 12. In order to ensure the coaxiality of the valve stem assembly 2, the valve core 11 and the valve stem 12 adopt an interference fit. The sound source control valve adopts a pressure balance design, and the pressure balance channel is composed of the valve body 1 and the end cover 4, so that the cross section of the valve stem assembly 2 and the valve port receive the same pressure to balance the pressure. Valve port when stem assembly 2 is closed area, stem the area of The areas of the circles are completely equal, and the valve stem assembly 2 is always in a state of pressure balance no matter when it is opened or when it is closed.

[0027] In the present invention, the force of the valve stem assembly of the sound source control valve is a constant high-pressure test requirement; the requirement for the electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com