Pillar type ceramic insulator

A porcelain insulator and ceramic insulation technology, applied in the direction of supporting insulators, etc., can solve the problems of inability to adjust the size and use, inconvenient bolt fixing stability, etc., and achieve the effect of compact structure, convenient adjustment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

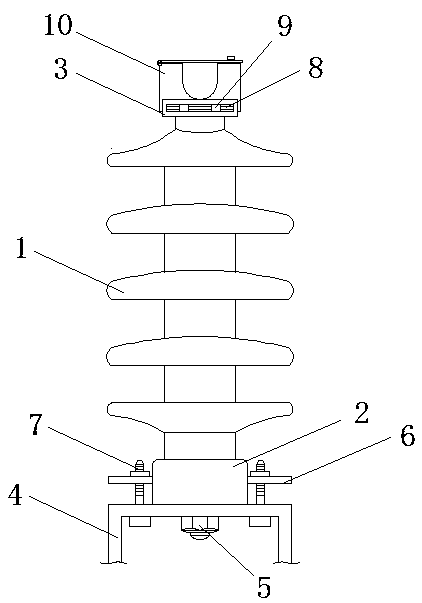

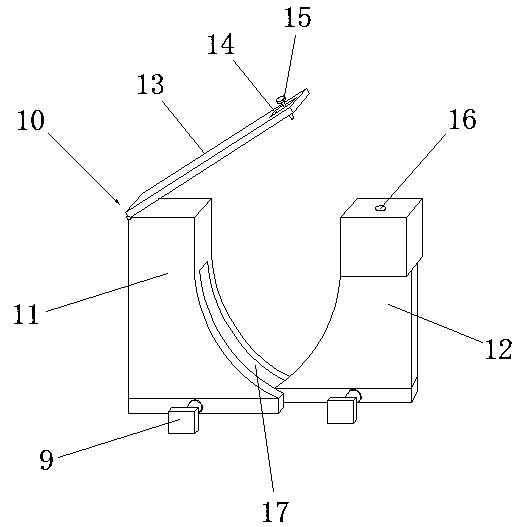

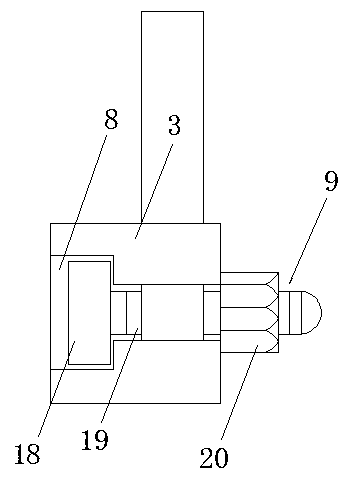

[0019] see Figure 1-2 As shown, a column type porcelain insulator includes a ceramic insulating core 1, a steel sleeve base 2 and a mounting frame 4, the bottom end of the ceramic insulating core 1 is installed with a steel sleeve base 2, the top end is equipped with a support top 3, and the top end of the support top 3 is installed Stringing mechanism 10; the mounting frame 4 is installed on the top of the high-voltage electric pole, and the bottom end of the steel sleeve base 2 is fixed on the top of the mounting frame 4 by the main bolt 5; the stringing mechanism 10 is composed of two mutually symmetrical first movable seats 11 and The second movable seat 12 is formed, and the opposite faces of the two movable seats are arc surfaces, the opposite side of the first movable seat 11 and the second movable seat 12 is provided with a slot 17, and the bottom end of the second movable seat 12 passes through the plug The bottom end of groove 17 and second movable seat 12 is plugge...

Embodiment 2

[0021] In addition, refer to Figure 1-3 , both sides of the outer wall of the steel sleeve base 2 are welded with connecting plates 6, and the connecting plates 6 are connected with the mounting frame 4 through positioning bolts 7, and the two positioning bolts 7 on the connecting plate 6 play the role of auxiliary fixing, sharing the main The pressure of the bolt 5 makes the installation of the ceramic insulating core 1 more stable. The top of the second movable seat 12 is provided with a screw hole 16, and the top plate 13 is provided with a movable groove 14 near an end of the second movable seat 12. Between the fixing screw 15 and the movable groove 14 The fixed screw 15 passes through the movable groove 14 and is installed in the screw hole 16. The length of the top plate 13 is constant. When the distance between the two movable seats changes, the movable groove 14 can facilitate the fixed screw 15 to always be inserted into the screw hole. In 16, the first movable seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com