Safety protective fence for electric power construction equipment

A technology for electric power construction and protective fences, applied in fences, photovoltaic power generation, electrical components, etc., can solve problems such as inconvenient transportation, poor wind protection ability, and regular maintenance, so as to reduce the trouble of handling, improve the service life, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

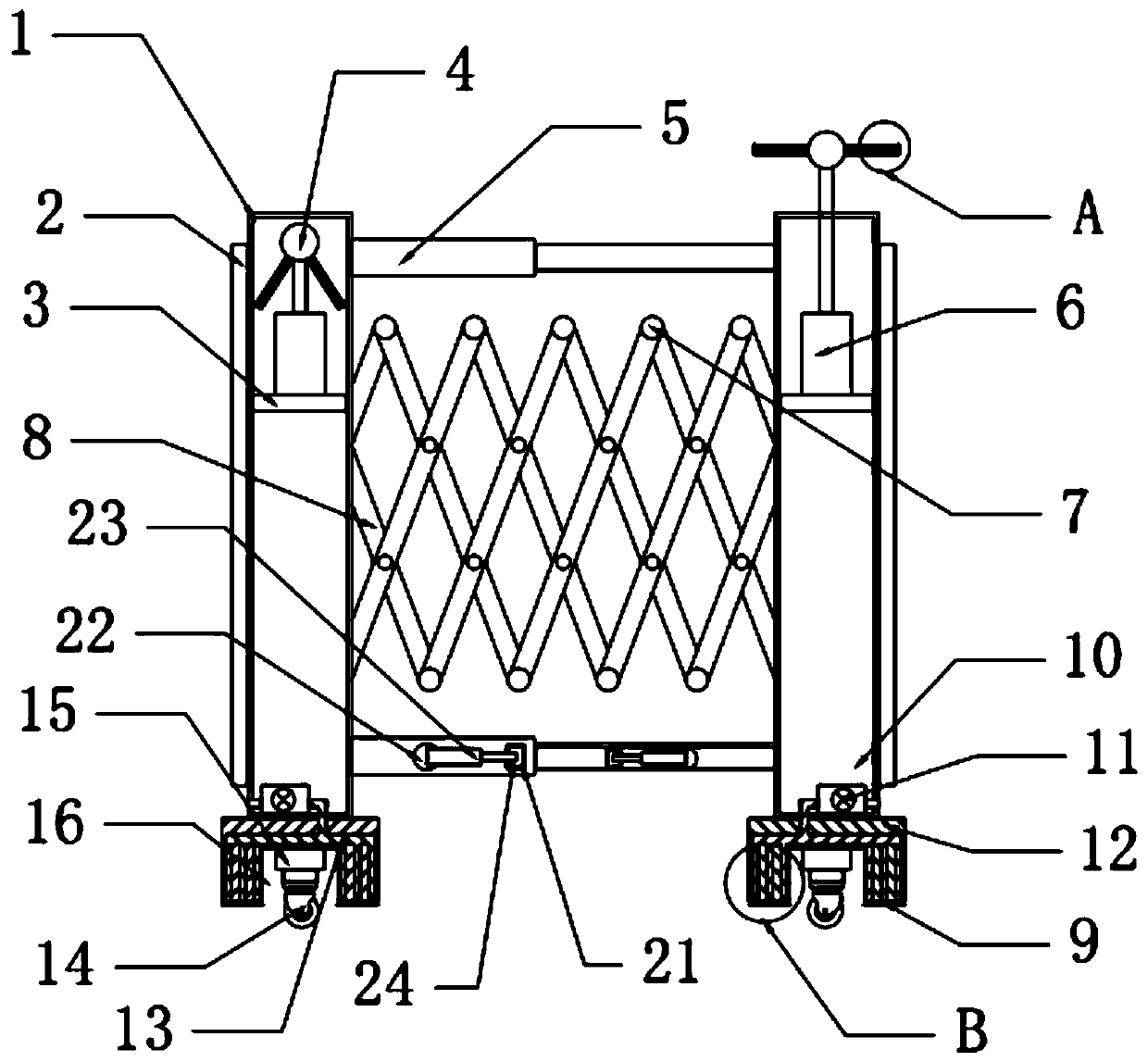

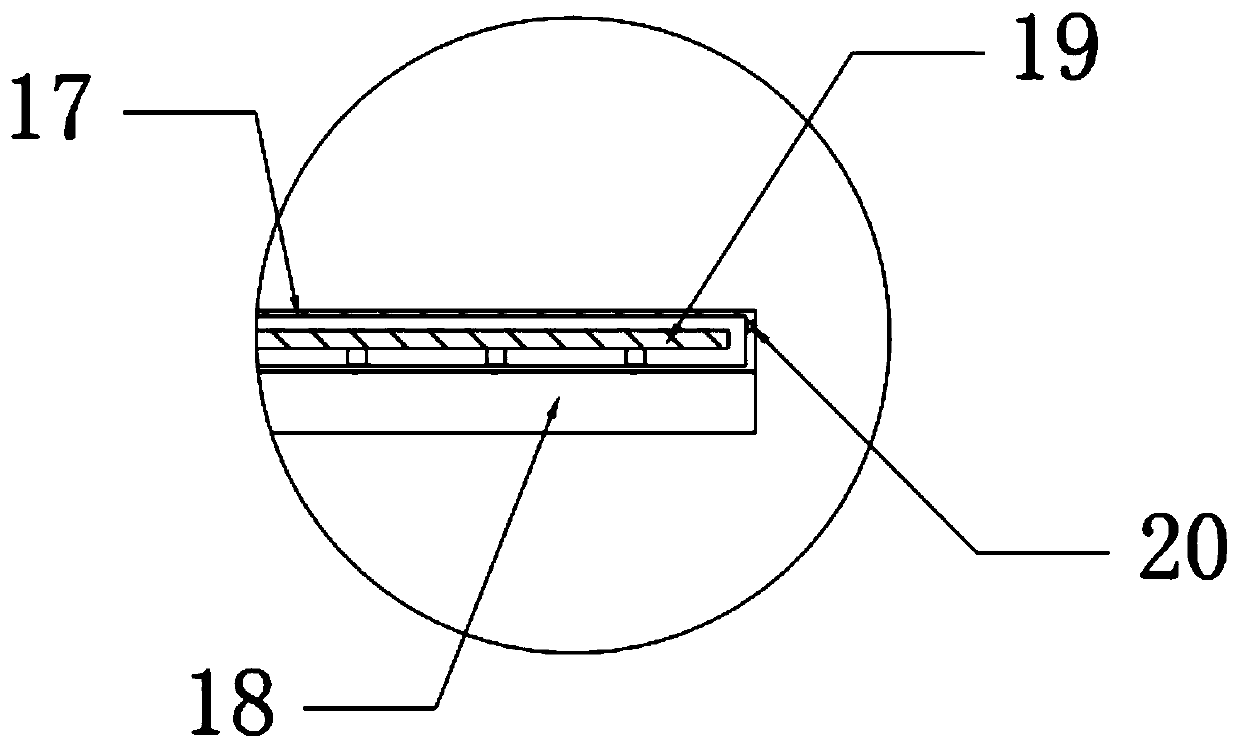

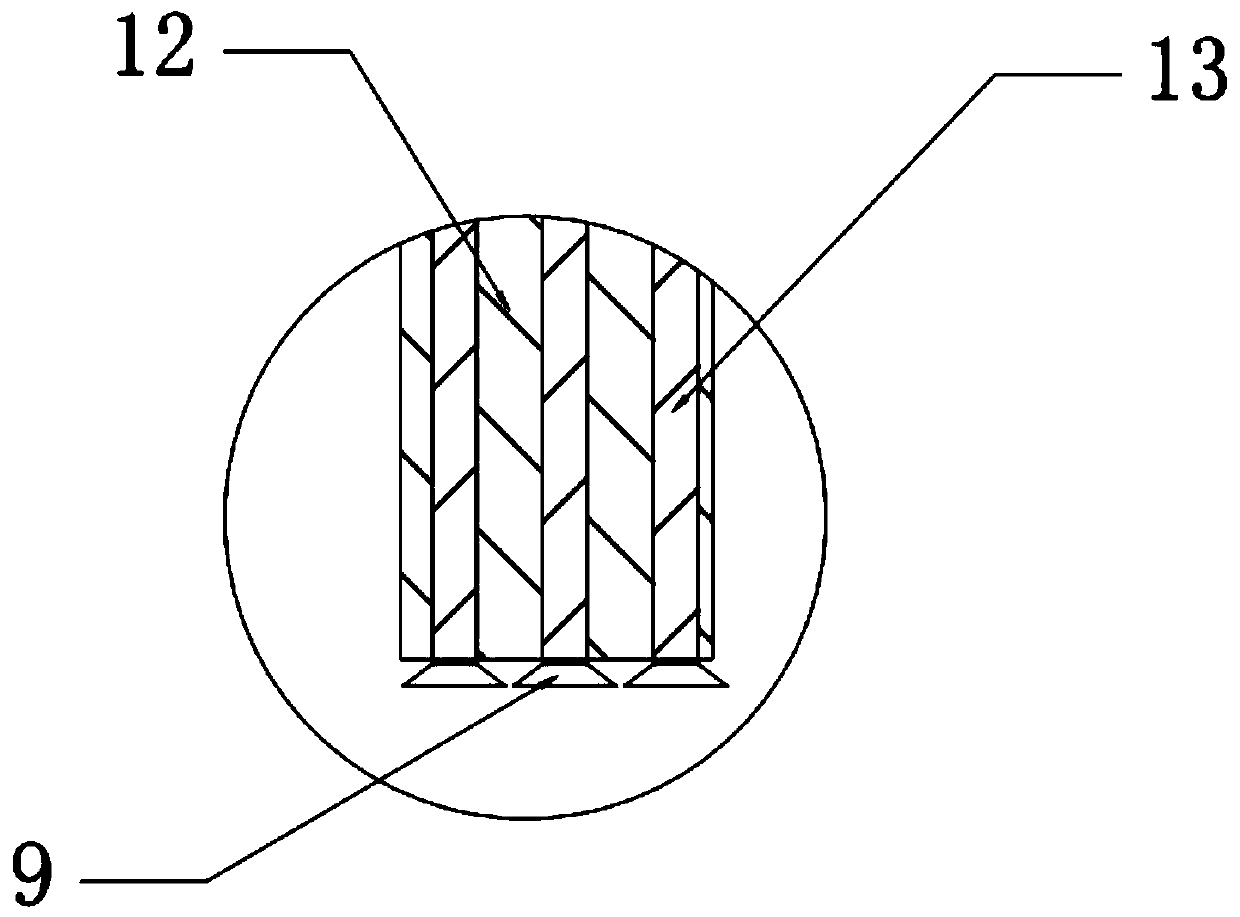

[0023] see Figure 1~3 , in an embodiment of the present invention, a safety fence for electric power construction equipment includes a column 1, a base 12 and a fixing device 10, a fixing plate 3 is arranged on the inner side of the upper end of the column 1, and the fixing plate 3 is fixedly connected to the column 1. The top of the fixed plate 3 is provided with a solar device, the solar device is connected to the battery, the bottom of the column 1 is provided with a base 12, the column 1 is fixedly connected to the base 12, and the lower end of the column 1 and the inner side of the base 12 are provided with a fixed Device 10, two first telescopic rods 5 are arranged between the two columns 1, the first telescopic rods 5 are fixedly connected with the column 1, and stabilizing devices are provided on the front and rear sides of the first telescopic rod 5 on the lower side, and the two first telescopic rods 5 A plurality of second movable rods 8 are arranged between the te...

Embodiment 2

[0028]An implementation of electric power construction, comprising the safety protection fence for electric power construction equipment described in Embodiment 1.

[0029] The safety fence for electric power construction equipment can facilitate the transfer of the fence by arranging universal wheels 14, which reduces the trouble of handling. Safety, by arranging a stabilizing device, the wind resistance of the guardrail can be strengthened, which is beneficial to improve the stability of the guardrail. By setting the vent 20, the interior of the solar device is ventilated smoothly. Furthermore, the setting of the support block makes it possible to save energy in rainy days. At the same time, even if water enters the interior of the solar device, the solar panel 19 will not be soaked in rainwater for a long time. At the same time, the vent 20 can also play a role in draining water during solar terms in rainy days, thereby directly improving the service life of the solar device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com