Intelligent thickness tester for optical glass production

A technology for optical lenses and testers, applied in the direction of instruments, measuring devices, etc., can solve problems such as scratches and unfavorable protection of lenses, and achieve the effect of preventing damage to lenses and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

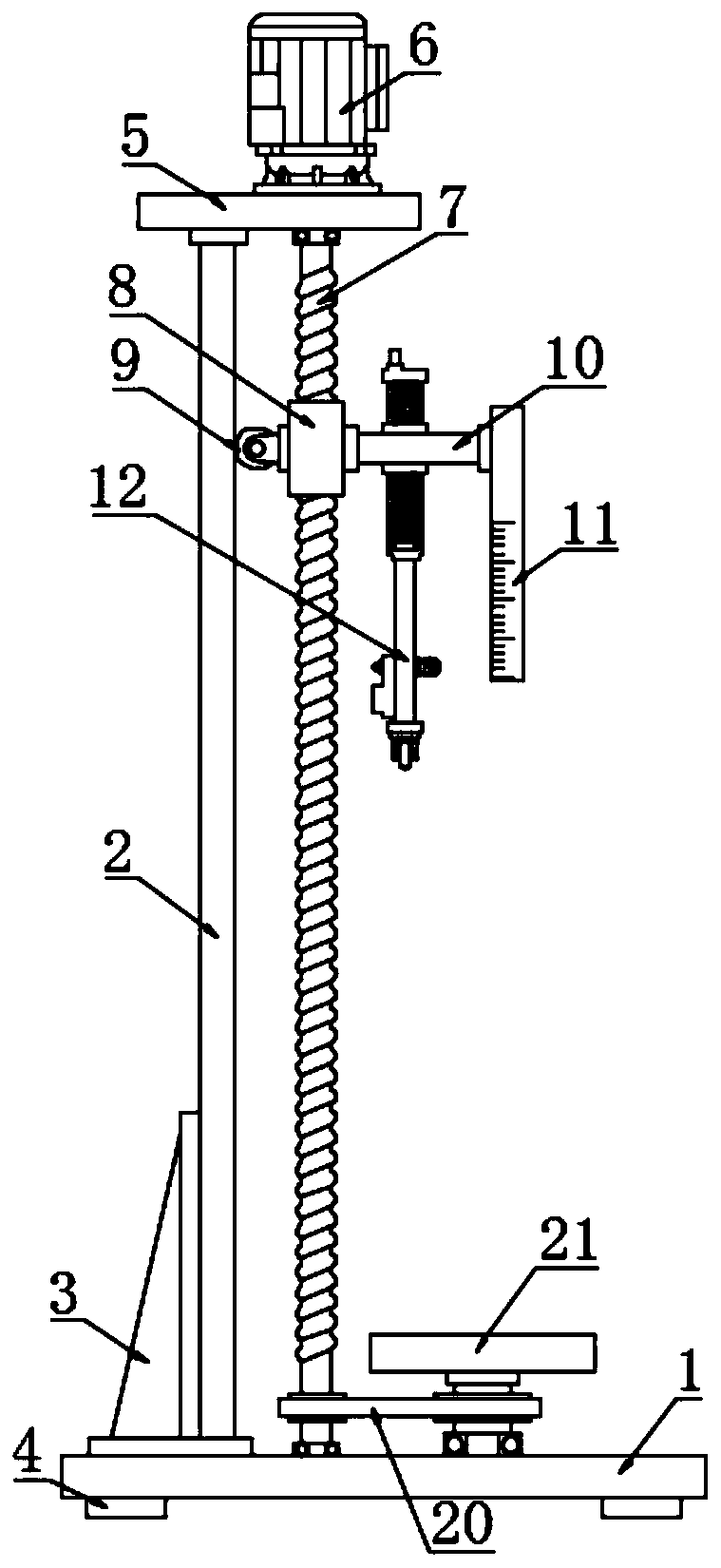

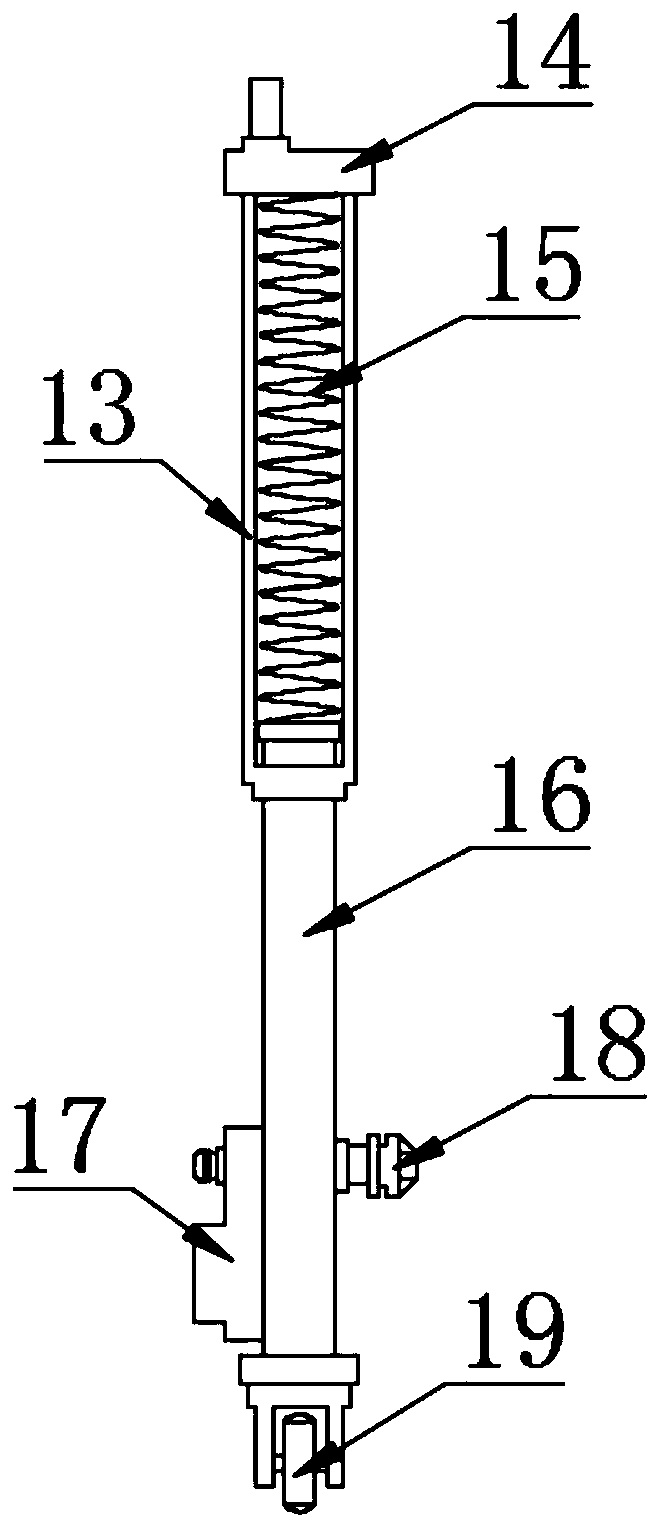

[0021] see Figure 1~3 , in an embodiment of the present invention, an intelligent thickness tester for optical lens production, comprising a base 1, a top plate 5, a screw rod 7, an elastic measuring device 12, and a tray 21; pads 4 are fixed at the four corners below the base 1, Preferably, the spacer 4 is made of soft material, a support plate 2 is fixed above one side of the base 1, the side wall of the support plate 2 is fixedly connected to the base 1 through a reinforcing rib 3, and the upper end of the support plate 2 is fixedly connected with a top plate 5 , the flange above the top plate 5 is fixedly connected with a drive motor 6, the drive motor 6 is a servo motor whose output can be reversed, and the support force between the support plate 2 and the bottom plate 1 is strengthened through the rib 3 to prevent bending; The output end of the drive motor 6 is connected to the screw rod 7, the screw rod 7 passes through the top plate 5 and is connected to the bearing i...

Embodiment 2

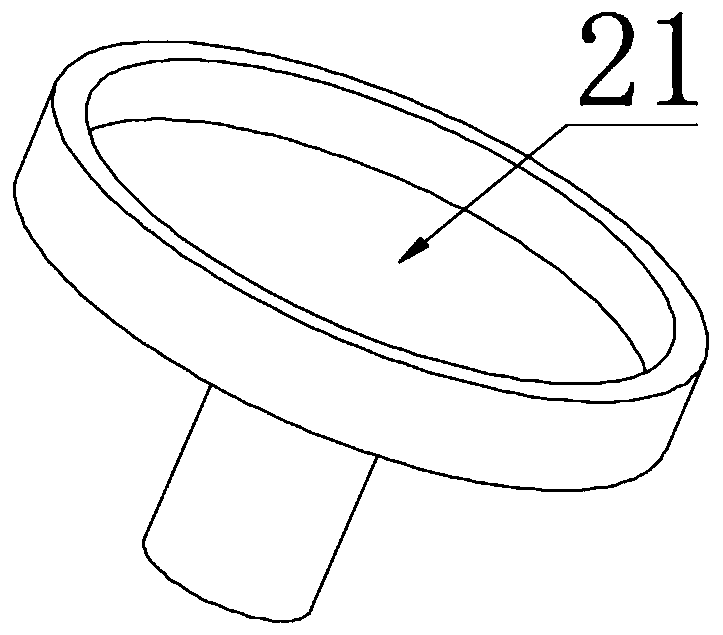

[0024] In order to further explain the above-mentioned intelligent thickness tester for optical lens production, this application provides another embodiment. The intelligent thickness tester for optical lens production in this embodiment has the following technical features: the bottom of the tray 21 passes through the rotating shaft bearing Rotate the connection base 1, the rotating shaft and the lower part of the screw rod 7 are connected through the timing belt 20, and the rotating screw rod 7 drives the rotating shaft and the tray 21 to follow the rotation through the timing belt 20, so as to realize the multi-directional detection function of the lens and the thickness of the lens in all directions For testing, the sample data is larger and more representative, the measurement results are more accurate, and the error is smaller.

[0025] According to the specific description of the above embodiment, it is easy to know that the working principle of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com