Method and system for analyzing red fire layer migration velocity in sintering pot test

A technology of migration speed and sintering cup, which is used in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of large amount of data, long time consumption, poor accuracy of results, etc., to achieve accurate measurement results and simple measurement methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

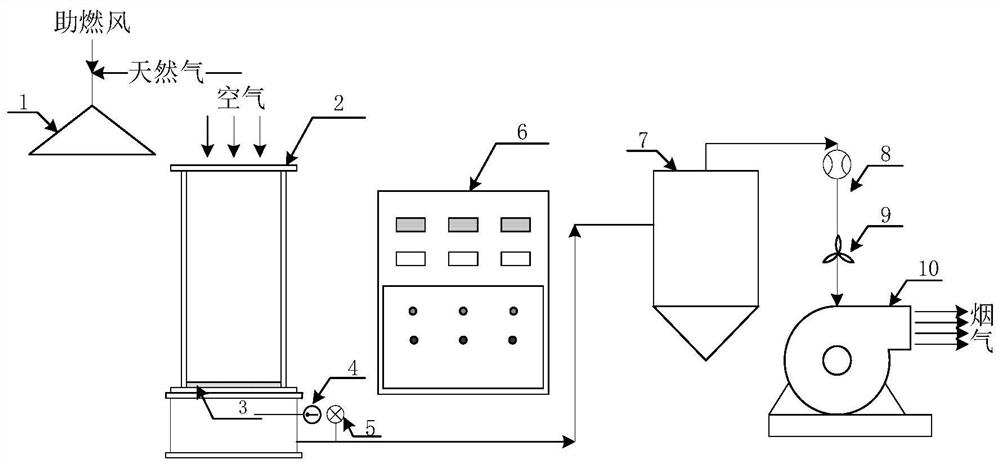

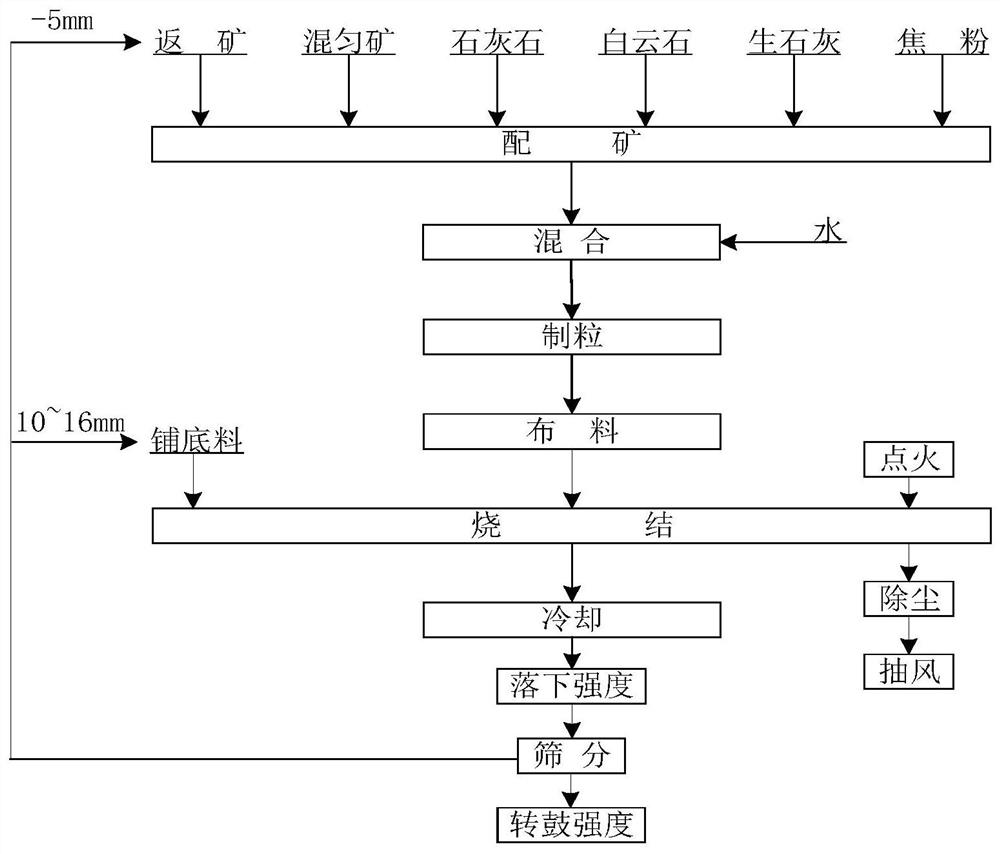

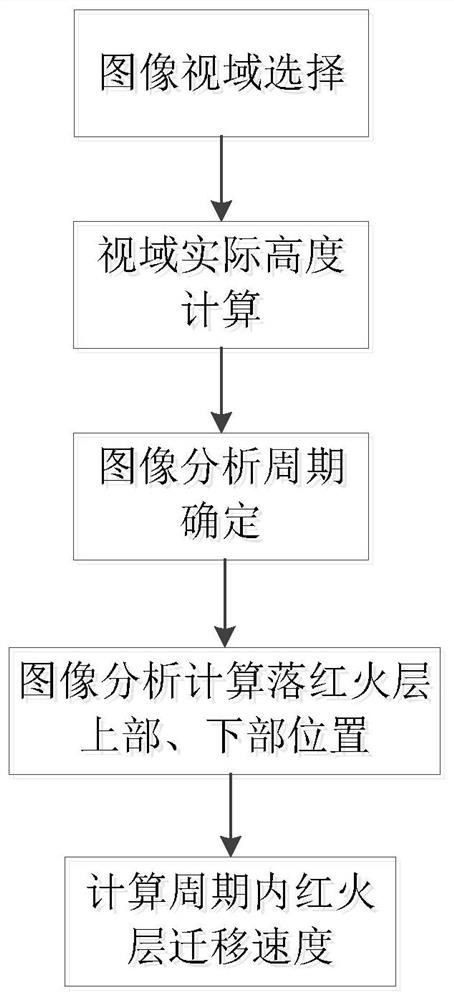

[0052]The technical scheme of the present invention is a method of collecting video images of the sintering process of a special sintering cup, and then analyzing and calculating the migration of the sintering red fire layer through a method for image recognition of the collected video (using VS2010 to develop a sintering cup test red fire layer migration image recognition software) speed. Include the following steps:

[0053] Step 1: Selection of the field of view of the lens image; see image 3 , Figure 4 , the camera is fixed with a bracket, and the line of sight is parallel to the ground surface. The entire field of view is shot on the side wall of the glass strip of the sintering cup, and the change of the sintering red fire layer can be observed through the glass strip. The selection of the lens image field of view is as follows: Figure 4 shown. The shooting direction of the camera is parallel to the horizon and passes through the side wall of the glass strip toward...

Embodiment 2

[0065] The actual height H of the field of view 实际 =0.74m, T=10s

[0066] t 1 , the upper position h of the red fire layer 上 =75.4cm, lower position h 下 =68.4cm

[0067] t 2 = t 1+ At time T, the position h in the upper part of the red fire layer 上 ’=74.4cm, lower position h 下 '=67.2cm

[0068] but:

[0069] t 1 ~t 2 During this cycle, the migration speed of the red fire layer

[0070] Example 2:

[0071] This embodiment provides a computer system, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the computer program, the steps of the foregoing embodiments are implemented.

[0072] In summary, the present invention analyzes and calculates the migration speed of the sintering red fire layer through the video image of the special sintering cup sintering process collected, through the method of image recognition (using VS2010 to develop the red fire layer migration image recognit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com