A centrifugal casting machine for special-shaped iron castings

A technology for centrifugal casting machines and iron castings, applied in the field of centrifugal casting machines for special-shaped iron castings, can solve the problem that centrifugal casting machines cannot cast special-shaped parts, etc., and achieve the effects of expanding casting range, ensuring quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

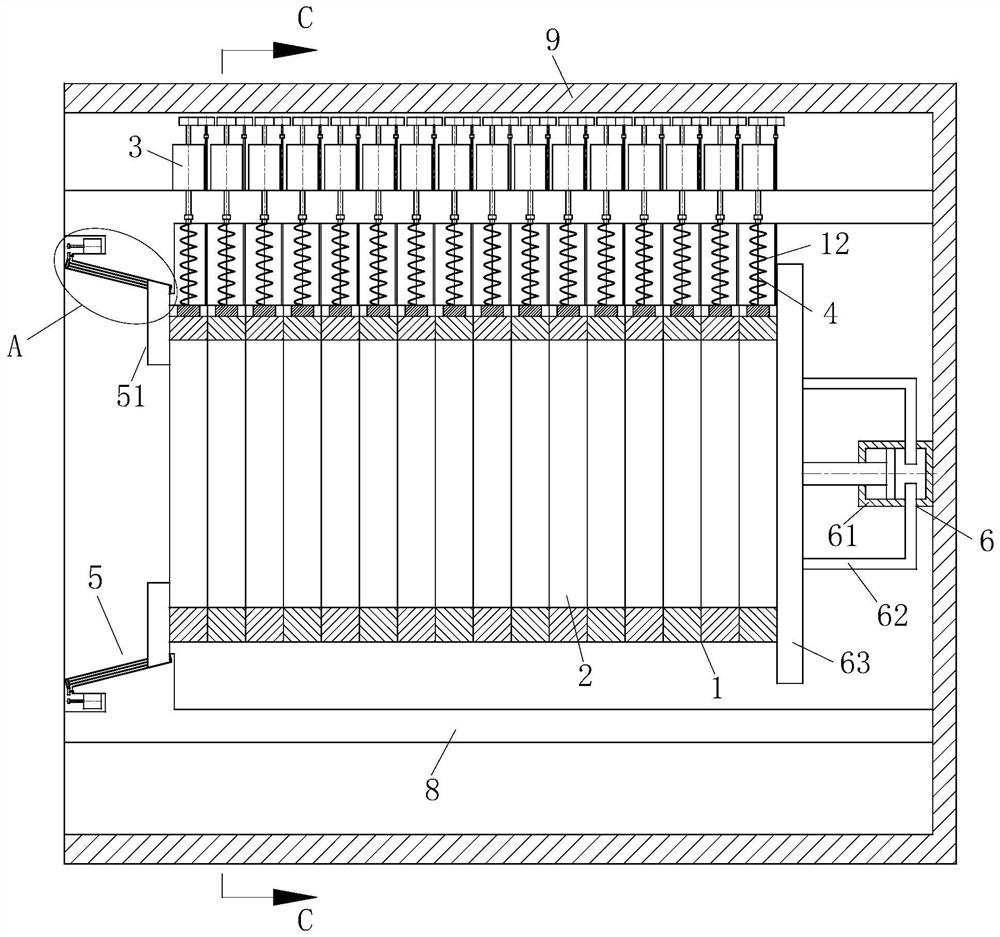

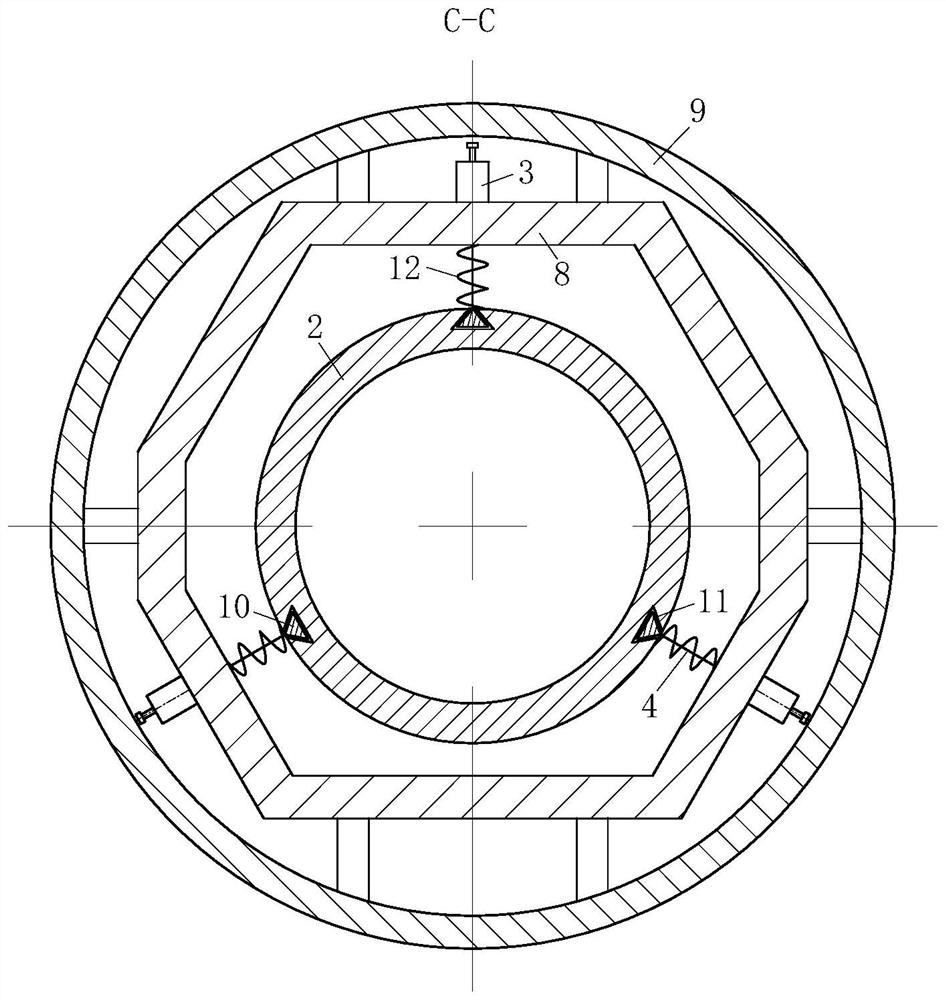

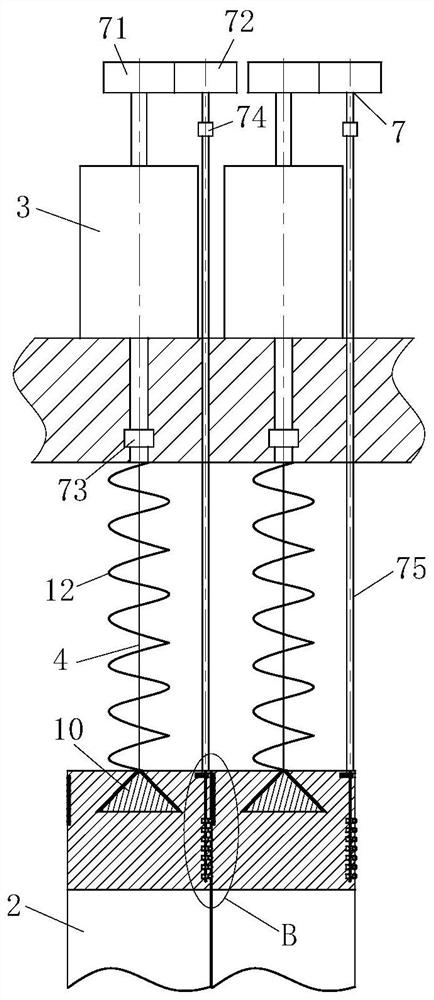

[0024] use Figure 1-Figure 6 A special-shaped iron casting centrifugal casting machine according to an embodiment of the present invention will be described as follows.

[0025] Such as Figure 1-Figure 2 As shown, a centrifugal casting machine for special-shaped iron castings according to the present invention includes an inner casting tube 1, a fixing module 5, a pressing module 6, a locking module 7 and an outer casting tube 9, and the inner casting tube 1 is composed of multiple A combination of two casting rings 2; the outside of the inner casting tube 1 is provided with a fixed frame 8, the outside of the fixed frame 8 is connected with the outer casting tube 9 through a connecting rod, and three sets of first motors are arranged on the outside of the fixed frame 8 at equal angles. 3. The number of first motors 3 in each group is set to be multiple, each first motor 3 corresponds to a casting ring 2, the output shaft of the first motor 3 is connected to the rigid rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com