Semi-automatic turbocharger shell casting production line

A turbocharger and casting production line technology, applied in foundry workshops, casting equipment, casting molding equipment, etc., can solve problems such as high labor intensity, production errors, quality impact, and complicated processes, and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

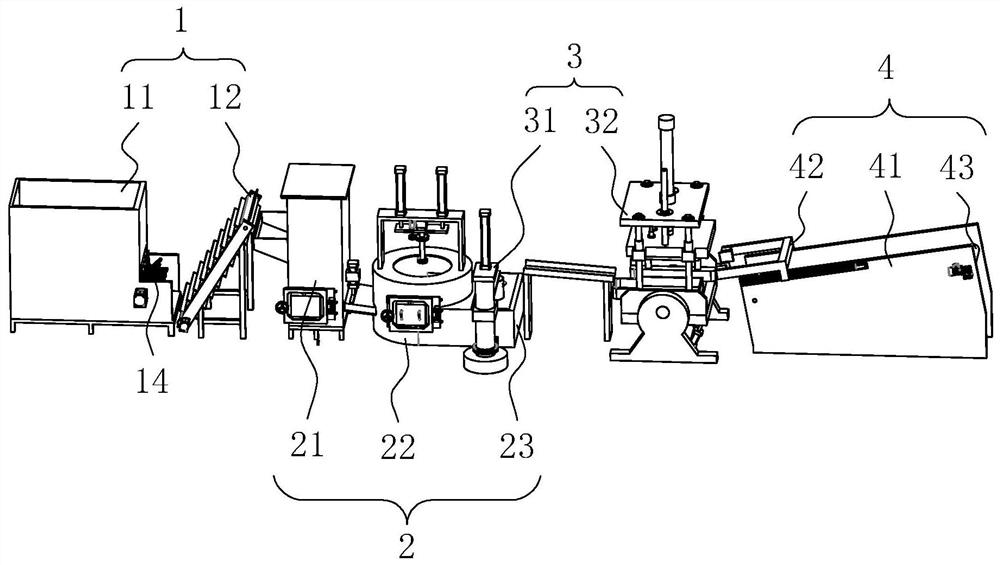

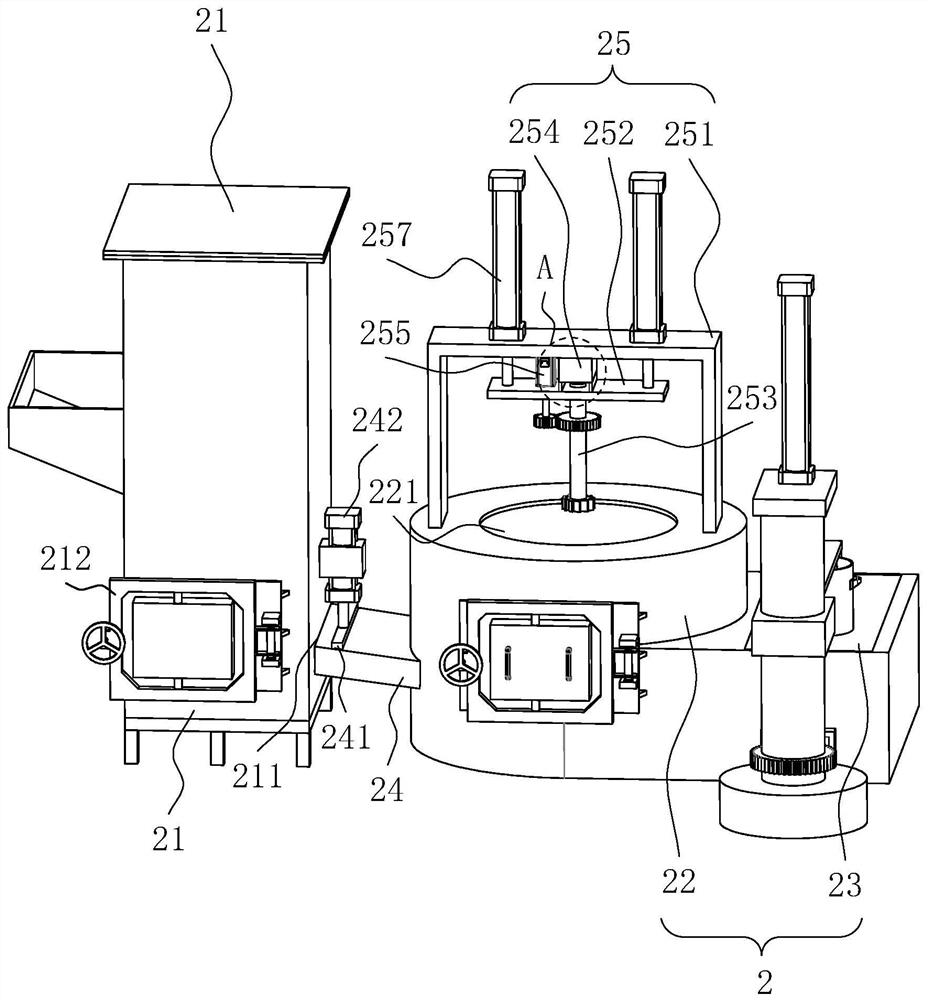

[0041] The following is attached Figure 1-9 The application is described in further detail.

[0042] The embodiment of the present application discloses a semi-automatic turbocharger shell casting production line. refer to figure 1 , a semi-automatic turbocharger casing casting production line includes a feeding device 1, a smelting device 2, a casting device 3, and a discharging device 4 arranged in sequence. The feeding device 1 transports aluminum blocks to a smelting device 2, and the smelting device 2 The aluminum block is melted into molten aluminum, and then the casting device 3 is used to cast the turbocharger casing, and then the formed turbocharger casing is transported to the next processing area through the discharging device 4 .

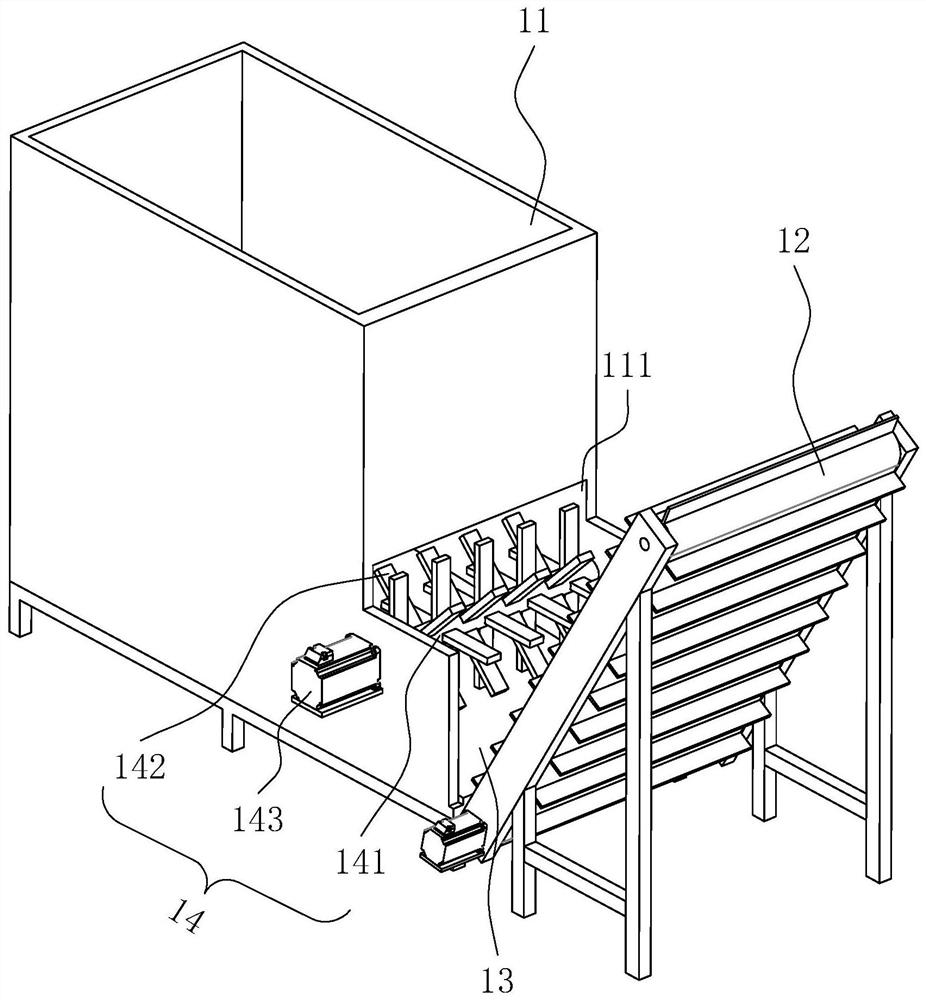

[0043] refer to figure 1 and figure 2 , the feeding device 1 includes a storage bin 11 and a conveyor 12, the storage bin 11 is fixedly arranged on the ground, the conveyor 12 is arranged on the side of the storage bin 11 close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com