A steam turbine low-pressure cylinder shaft seal dimple processing device and method

A processing method and processing device technology, applied to feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting the safe and economical operation of the unit, vacuum degree drop, air leakage, etc., and achieve stable and reliable spindle operation without Jamming, eliminating the effect of excessive meshing clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

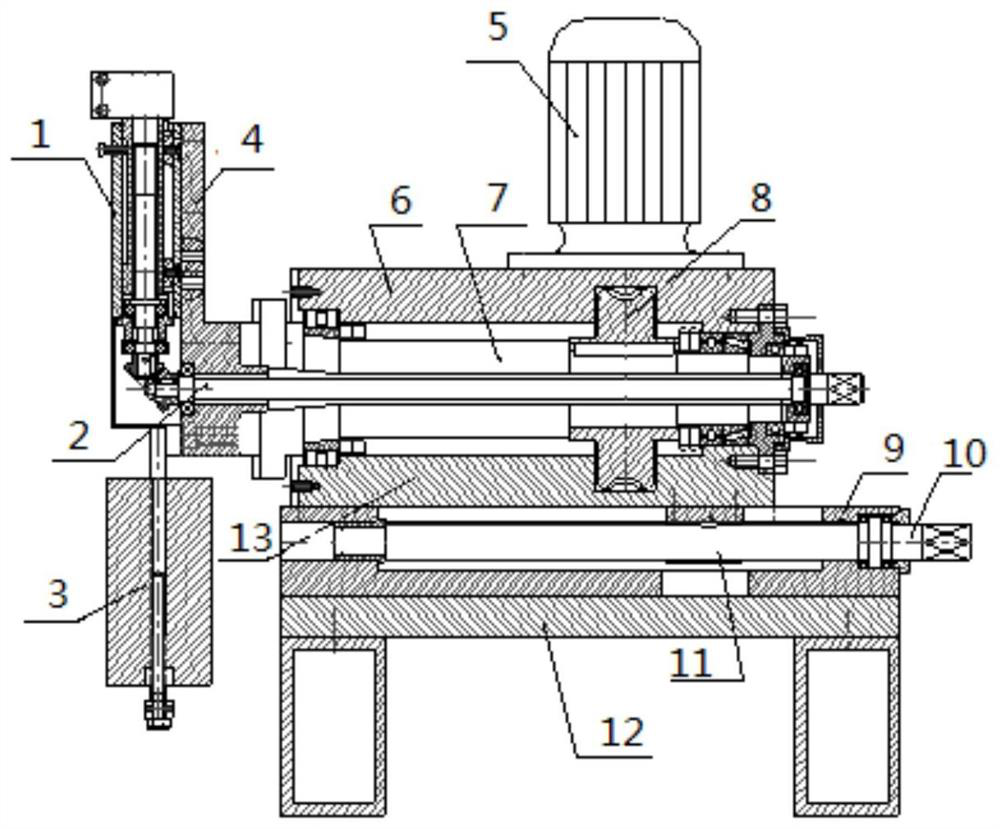

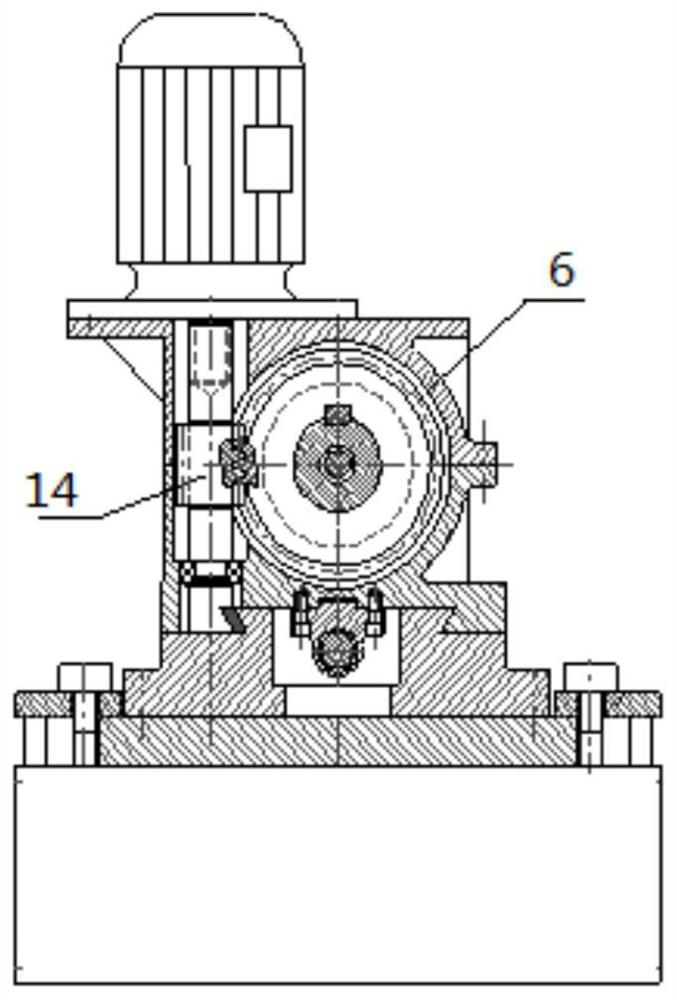

[0025] see Figure 1-2 , the present invention provides a steam turbine low-pressure cylinder shaft seal dimple processing device, including a tool holder assembly 1, an upper box 6 and a lower box 13, the lower box 13 is installed below the upper box 6, and the upper box 6 A hollow main shaft 7 is installed between the lower box body 13, and a drive shaft 2 is installed inside the hollow main shaft 7. The tool holder assembly 1 is installed on the outer wall of the upper box body 6 and the lower box body 13. The tool holder assembly 1 is equipped with a boring arm 4, a counterweight 3 is installed at the bottom of the tool holder assembly 1, a motor 5 is installed on the top of the upper box 6, a worm wheel 8 is installed inside the upper box 6, and the bottom of the lower box 13 A base 9 is installed, and the inside of the base 9 is equipped with an axial feed screw nut 11, and the internal thread of the axial feed screw nut 11 is equipped with an axial feed screw 10, and th...

Embodiment 2

[0033] see Figure 1-2 , the present invention provides a steam turbine low-pressure cylinder shaft seal dimple processing device, including a tool holder assembly 1, an upper box 6 and a lower box 13, the lower box 13 is installed below the upper box 6, and the upper box 6 A hollow main shaft 7 is installed between the lower box body 13, and a drive shaft 2 is installed inside the hollow main shaft 7. The tool holder assembly 1 is installed on the outer wall of the upper box body 6 and the lower box body 13. The tool holder assembly 1 is equipped with a boring arm 4, a counterweight 3 is installed at the bottom of the tool holder assembly 1, a motor 5 is installed on the top of the upper box 6, a worm wheel 8 is installed inside the upper box 6, and the bottom of the lower box 13 A base 9 is installed, and the inside of the base 9 is equipped with an axial feed screw nut 11, and the internal thread of the axial feed screw nut 11 is equipped with an axial feed screw 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com