A Design Method of High Durability Spoke Bottom

A design method and durability technology, applied in the direction of wheels, spoke-plate wheels, rolling resistance optimization, etc., can solve the problems of reduced stiffness and durability of the bottom of the spoke and spoke, the outer mounting surface cannot be completely attached to the loading plate, and the contact area is reduced. problems, to achieve the effect of improving durability

Active Publication Date: 2022-05-31

东风汽车车轮随州有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

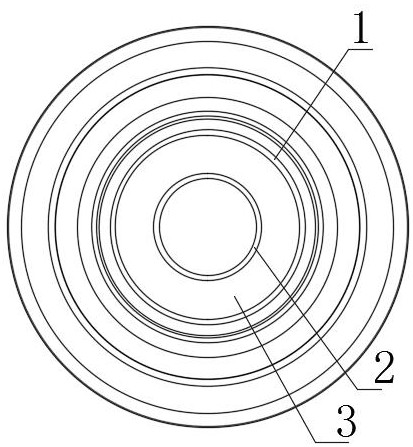

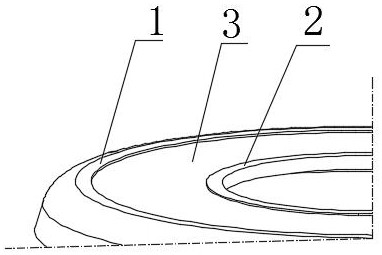

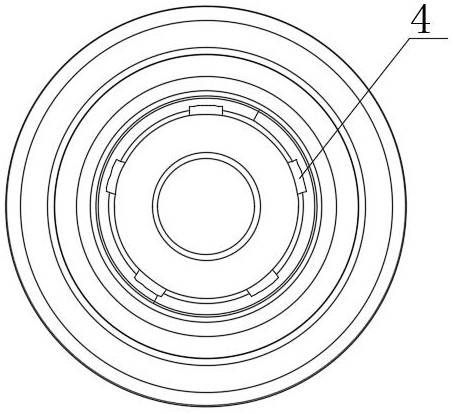

[0002] The wheel is a key part of the car, and its durability directly affects the fatigue life of the wheel and the safety performance of the vehicle. The spokes are mainly composed of two parts: a non-rotating structure at the spoke bottom and a rotating structure other than the spoke bottom. There are basically 3-5 inherent structural forms of the spoke bottom of steel wheels. When product developers design products, the spoke bottom generally adopts one of these forms directly. When doing structural optimization design, only the parameters of the rotary structure are selected. Optimization, to find the optimal gyration curve structure, and achieve the purpose of light weight by reducing the thickness of the spoke material under the premise of satisfying the fatigue performance of the product. However, for several common spoke bottom structures, reducing the material thickness can ensure the spoke The durability of the rotating body structure outside the bottom may not be able to meet the durability of the non-rotating body structure at the spoke bottom. The spoke bottom will fail first, and the durability of the spoke bottom will become the bottleneck of the entire spoke lightweight. How to design a high Durable spoke bottom structure, so that the failure point avoids the bottom of the spoke, the optimal state is obtained by optimizing the structural curve of the gyratory body outside the bottom of the spoke, and the technology that design engineers have been paying attention to is to minimize the thickness of the material to achieve the purpose of reducing the weight of the spoke difficulty

The outer mounting surfaces of the existing spoke bottoms are designed horizontally, but in reality, after loading the bolt pre-tightening force, the spoke bottoms will be deformed to a certain extent, resulting in the outer mounting surface not being able to fully attach to the loading plate, and the contact area is reduced, making the The stiffness and durability of the spoke base will be reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical fields of automobiles and mechanical engineering, in particular to a design method for spoke bottoms with high durability. The invention can greatly improve the durability of the spoke bottom through the unique design method of the spoke bottom, so that the failure point will not appear at the bottom of the spoke and spoke like the existing design method, avoiding the design bottleneck, and further optimizing the curve of the gyrator To achieve the purpose of lightweight.

Description

A design method for high-durability wheel spoke base technical field The present invention relates to automobile and mechanical engineering technical field, relate in particular to a kind of design method of high-durability wheel spoke bottom. Law. Background technique [0002] The wheel is a key component of an automobile, and its durability directly affects the fatigue life of the wheel and the safety performance of the entire vehicle. The wheel spoke is mainly composed of two parts: the non-rotating body structure at the base of the spoke and the rotating body structure outside the base of the spoke, while the existing steel cars on the market There are basically 3-5 inherent structural forms of the wheel spoke base. When product developers are designing products, the spoke base generally Directly use one of these forms, and only optimize the parameters for the structure of the rotating body in the structural optimization design to find the optimal design. On the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60B3/00B60B3/12

CPCY02T10/86

Inventor 袁飞王贤付华迎春刘旭

Owner 东风汽车车轮随州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com