Net bag and method for folding and packaging space rope net

A net bag and rope net technology, applied in the aerospace field, can solve the problems of uneven friction force between the rope net and the wall surface of the net bag, affect the stability of the rope net, and affect the waiting time, etc., and achieve practicability and optimized structural layout , fully functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

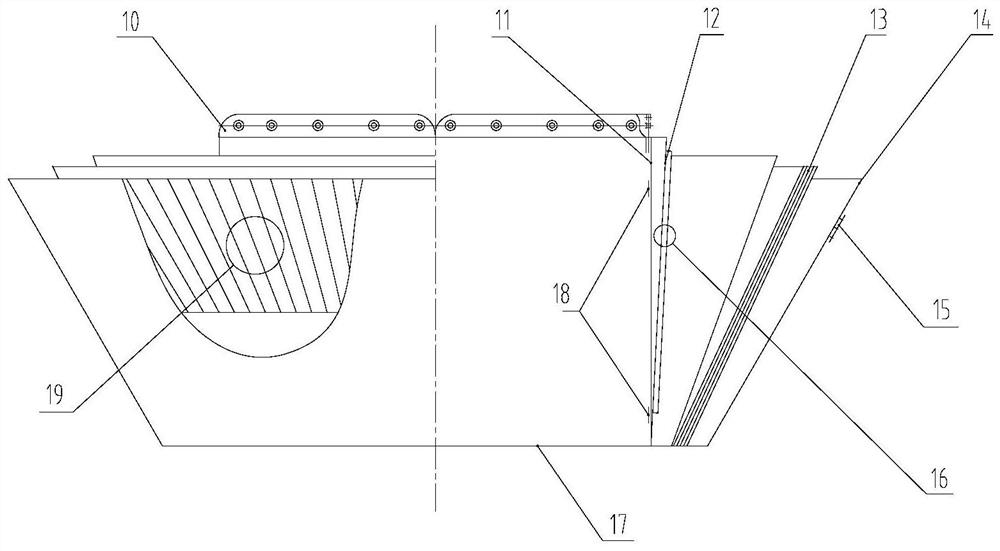

[0101] Example 1 is applicable to space capture rope net in space field

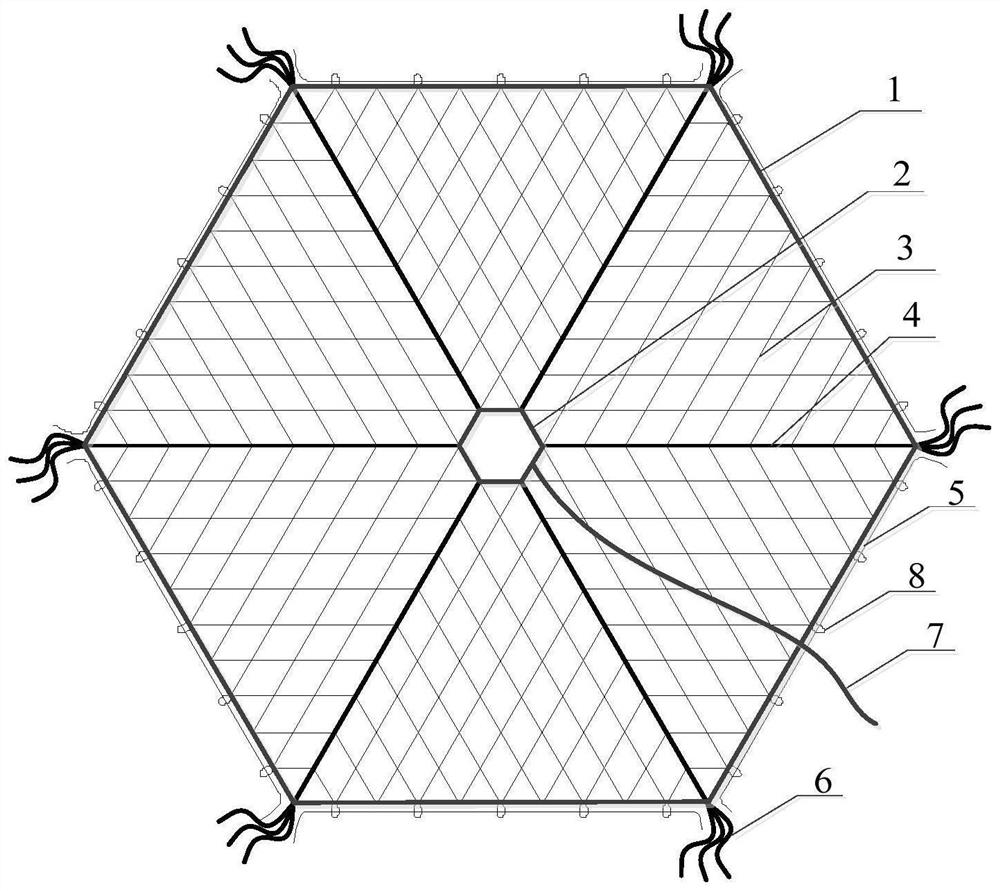

[0102] The space rope net is made of Fang III fiber, in which the frame rope is a 12-strand braided rope with a diameter of 3mm; the secondary rope is a 6-strand braided rope with a diameter of 1.5mm;

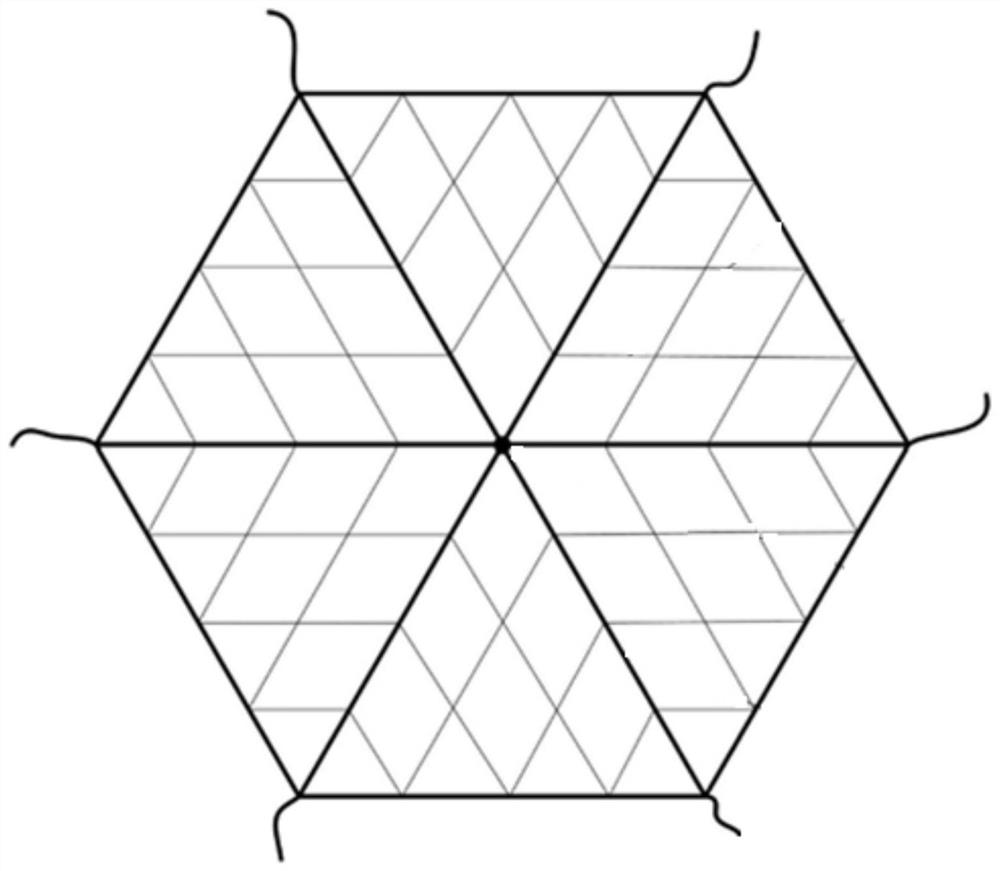

[0103] The whole net is a regular hexagon with an outer rope length of 18000mm, the center of the net is a regular hexagon with a length of 600mm, and the side length of the mesh is 600mm. The whole net is composed of 29 rings from the outside to the inside except the inner and outer ropes;

[0104] Cut 37500mm long diameter 3mm frame rope according to Figure 4 Do a single radial rope arrangement, a total of 3 groups;

[0105] Cut 3 sections of 610mm long frame rope with a diameter of 3mm as the inner ring rope to connect 3 groups of radial ropes;

[0106] Cut the 110000mm long frame rope with a diameter of 3mm as the outer ring rope and connect the 3 sets of radial ropes at the outermost layer;

[01...

example 2

[0112] Example 2 is applicable to space capture rope net in space field

[0113] Polyimide fiber is used to make netting ropes, in which the frame rope is 16-strand braided rope with a diameter of 2mm; the secondary rope is 8-strand braided rope with a diameter of 1mm;

[0114] The whole net is a regular hexagon with an outer side length of 15500mm, the center of the net is a regular hexagon with a length of 250mm, and the side length of the mesh is 250mm.

[0115] Cut 32500mm long frame rope with a diameter of 2mm to make a single group of radial rope arrangement, a total of 3 groups;

[0116] Cut 3 sections of 260mm long frame rope with a diameter of 2mm as the inner ring rope to connect 3 groups of radial ropes;

[0117] Cut the 95000mm long frame rope with a diameter of 2mm as the outer ring rope and connect the 3 sets of radial ropes at the outermost layer;

[0118] Use the secondary rope with a diameter of 1mm as the middle rope to start the outermost arrangement, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com