Puncture template based on optical positioning, auxiliary radiotherapy constant force tracking system realized by applying same, and constant force tracking method

An optical positioning and puncture template technology, which is applied in X-ray/γ-ray/particle irradiation therapy, etc., can solve the problems of uneven weight distribution of 3D printing templates, difficulty in tracking optical balls, and inability to track with constant force. The effect of high force tracking accuracy, easy maintenance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

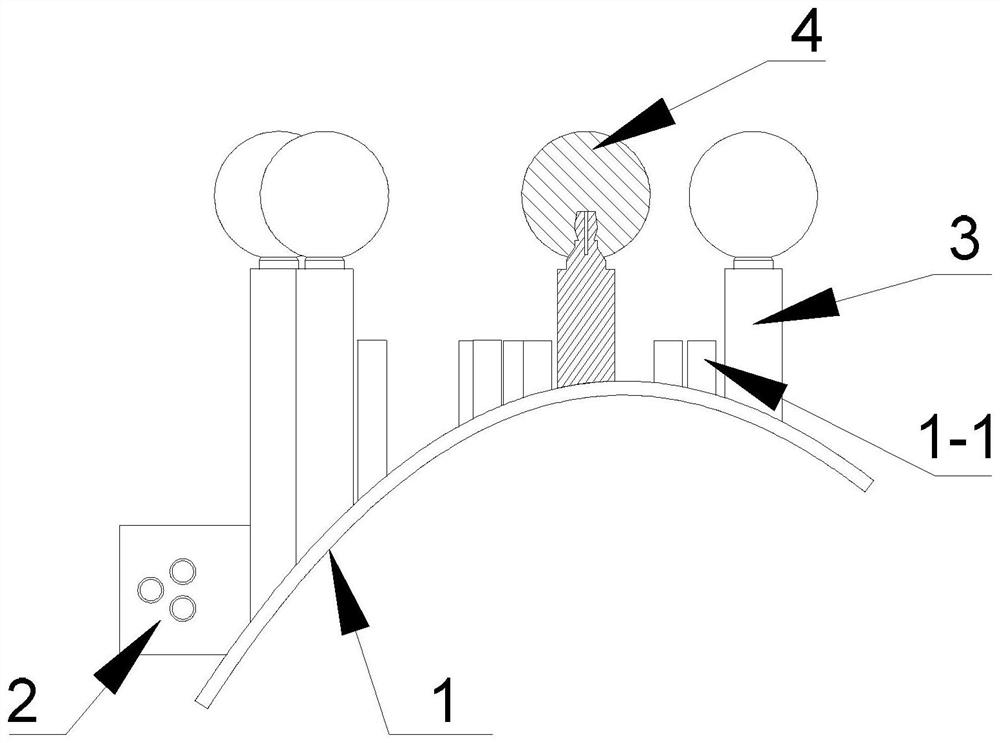

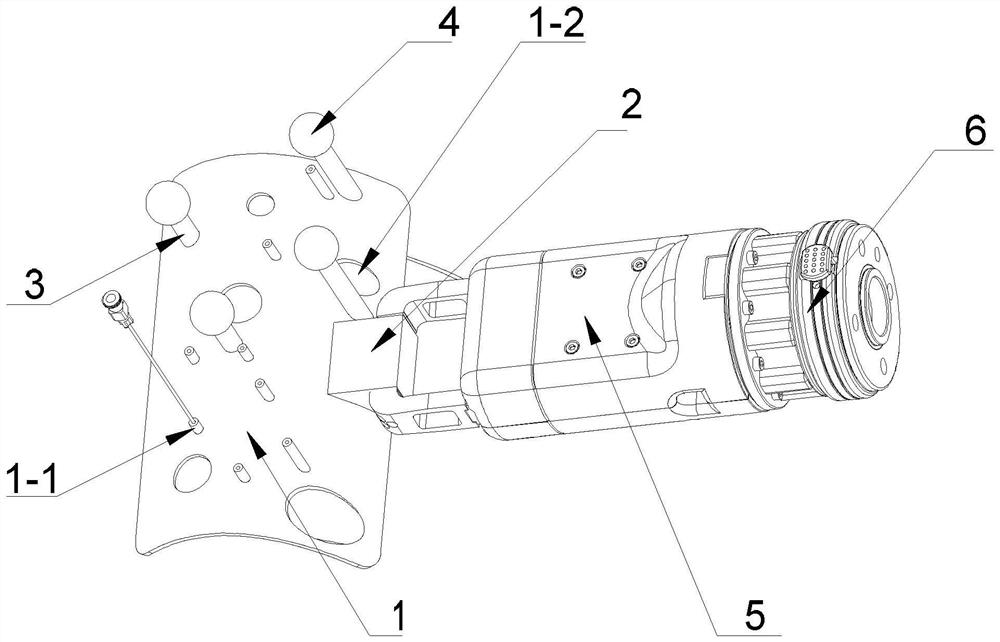

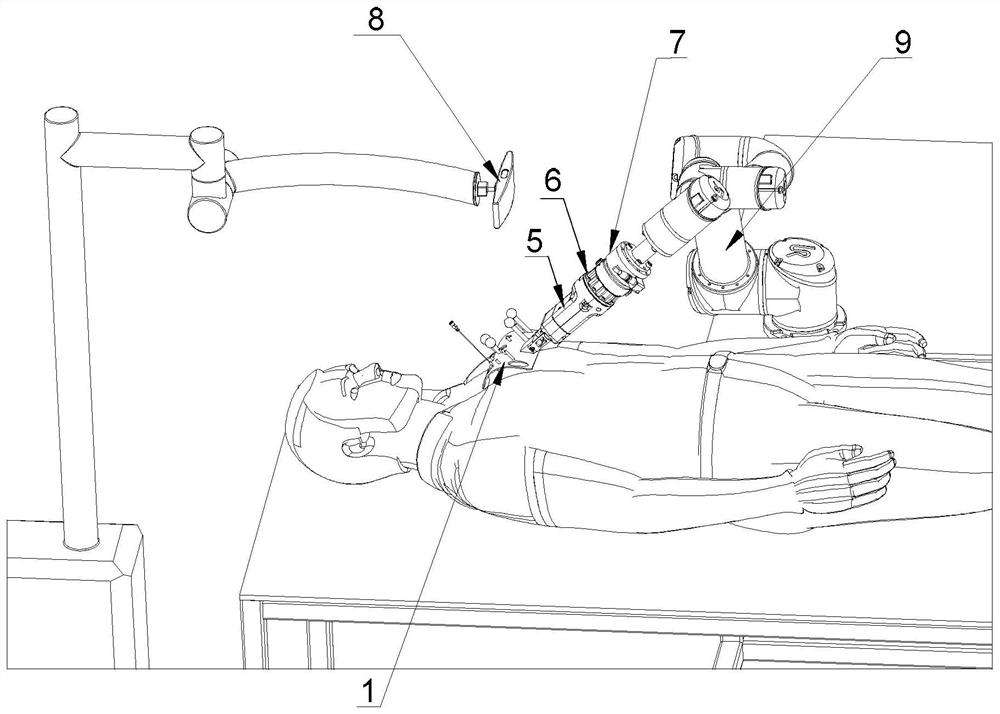

[0029] Specific implementation mode one: the following combination figure 1 with figure 2 Describe this embodiment. The puncture template based on optical positioning described in this embodiment includes a 3D printing template 1 and a clamping connector 2, and also includes N positioning reference columns 3 and N optical balls 4; N is an integer;

[0030] The clamping connector 2 is fixed at the middle part of the lower end of the 3D printing template 1;

[0031] The 3D printing template 1 is a curved surface structure, and a plurality of puncture needle tracks 1-1 are arranged on it;

[0032] N positioning reference columns 3 are fixed on the upper surface of the 3D printing template 1, and an optical ball 4 is fixed on the top of each positioning reference column 3;

[0033] The middle part of the lower end of the 3D printing template 1 is provided with a clamping connector 2 , and the clamping connector 2 is used for fixed connection with the clamping jaw 5 on the mecha...

specific Embodiment approach 2

[0035] Specific implementation mode two: the following combination figure 1 with figure 2 This embodiment will be described. This embodiment will further describe the first embodiment. The upper surface of the 3D printing template 1 is provided with a plurality of hollow holes 1-2.

[0036] In this preferred embodiment, by adding hollow holes 1-2, the weight of the 3D printing template 1 is further reduced, which is convenient for operation. In a specific application, the sizes of the multiple hollow holes 1-2 are different, and the center of mass of the balanced 3D printing template 1 is at the center of the 3D printing template 1 as a reference.

specific Embodiment approach 3

[0037] Specific implementation mode three: the following combination figure 1 This embodiment will be described. This embodiment will further describe the first embodiment. The top end of the positioning reference column 3 and the optical ball 4 are fixed by plugging.

[0038] In this preferred embodiment, the top end of the positioning reference column 3 and the optical ball 4 are fixed through a plugging connection, so that the structure is simple and the assembly and disassembly are convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com