Novel cylindrical roller bearing of holder structure

A technology for cylindrical roller bearings and cages, applied in rolling contact bearings, bearings for rotational motion, bearings, etc., can solve the problems of shortened bearing life, large impact loads, wear of cages and rolling elements, etc., to reduce wear, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and embodiment:.

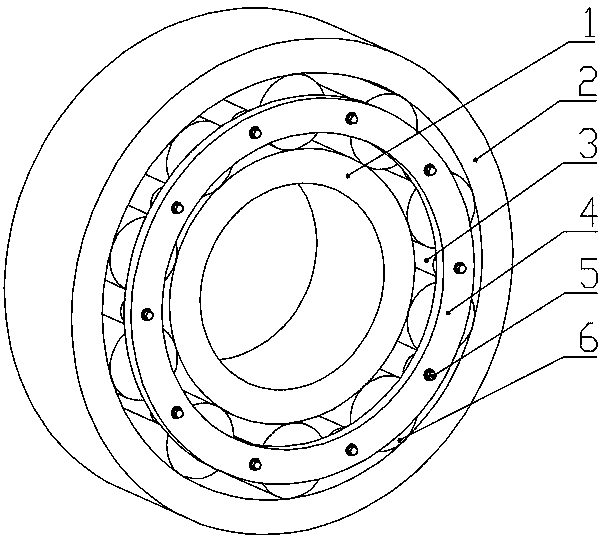

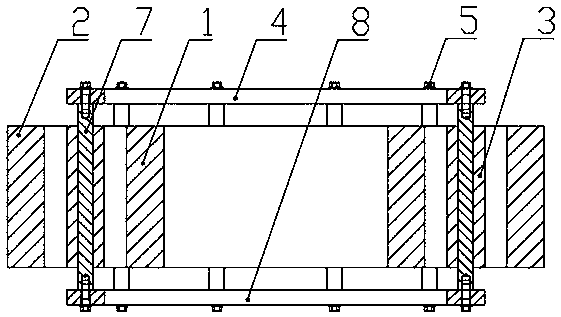

[0012] as attached figure 1 As shown, the present invention includes an inner ring 1, an outer ring 2, a cage roller 3, a side plate I4, a screw 5, a rolling body 6, a pin shaft 7, and a side plate II8. The cage is composed of cage roller 3, side plate Ⅰ4, screw 5, pin shaft 7 and side plate Ⅱ8; Plate Ⅰ4 is connected to side plate Ⅱ8, and pin shafts 7 are distributed at equal intervals in the circumferential direction; rolling elements 6 are placed in holes formed between two cage rollers 3; inner ring 1 is placed on the inner side of side plate Ⅰ4 and side plate Ⅱ8 , connected with the rolling body 6; the outer ring 2 is placed on the outside of the side plate Ⅰ4 and the side plate Ⅱ8, and connected with the rolling body 6. fall.

[0013] Working principle of the present invention is as follows:.

[0014] When the bearing is running, the outer ring 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com