Energy storage rebounding fruit picking equipment

A kind of equipment and fruit-picking technology, which is applied in the direction of picking machines, agricultural machinery and implements, etc., can solve the problems of high labor cost, low return rate, and fruit damage, and achieve the effect of avoiding fruit damage and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

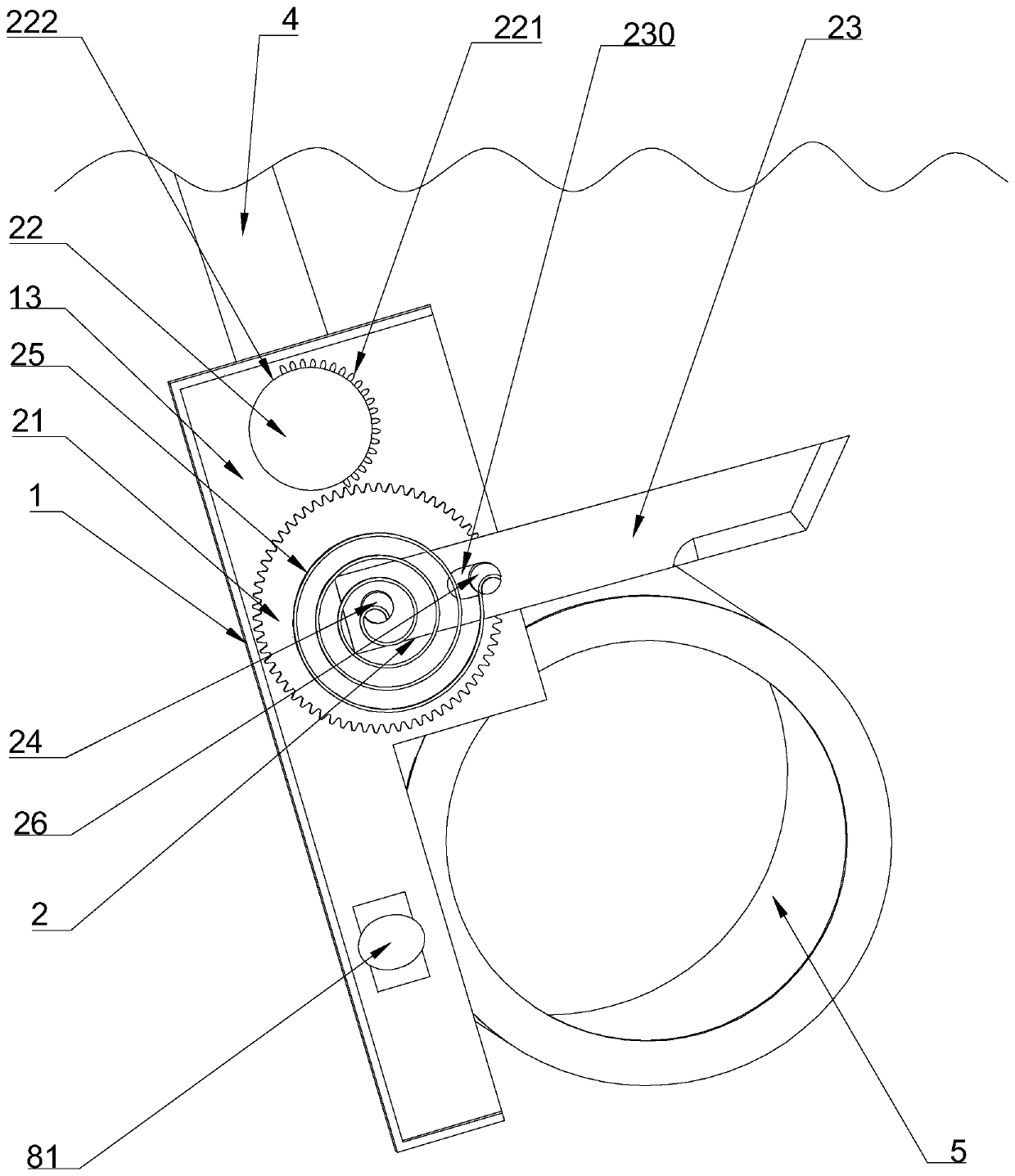

Method used

Image

Examples

specific Embodiment approach

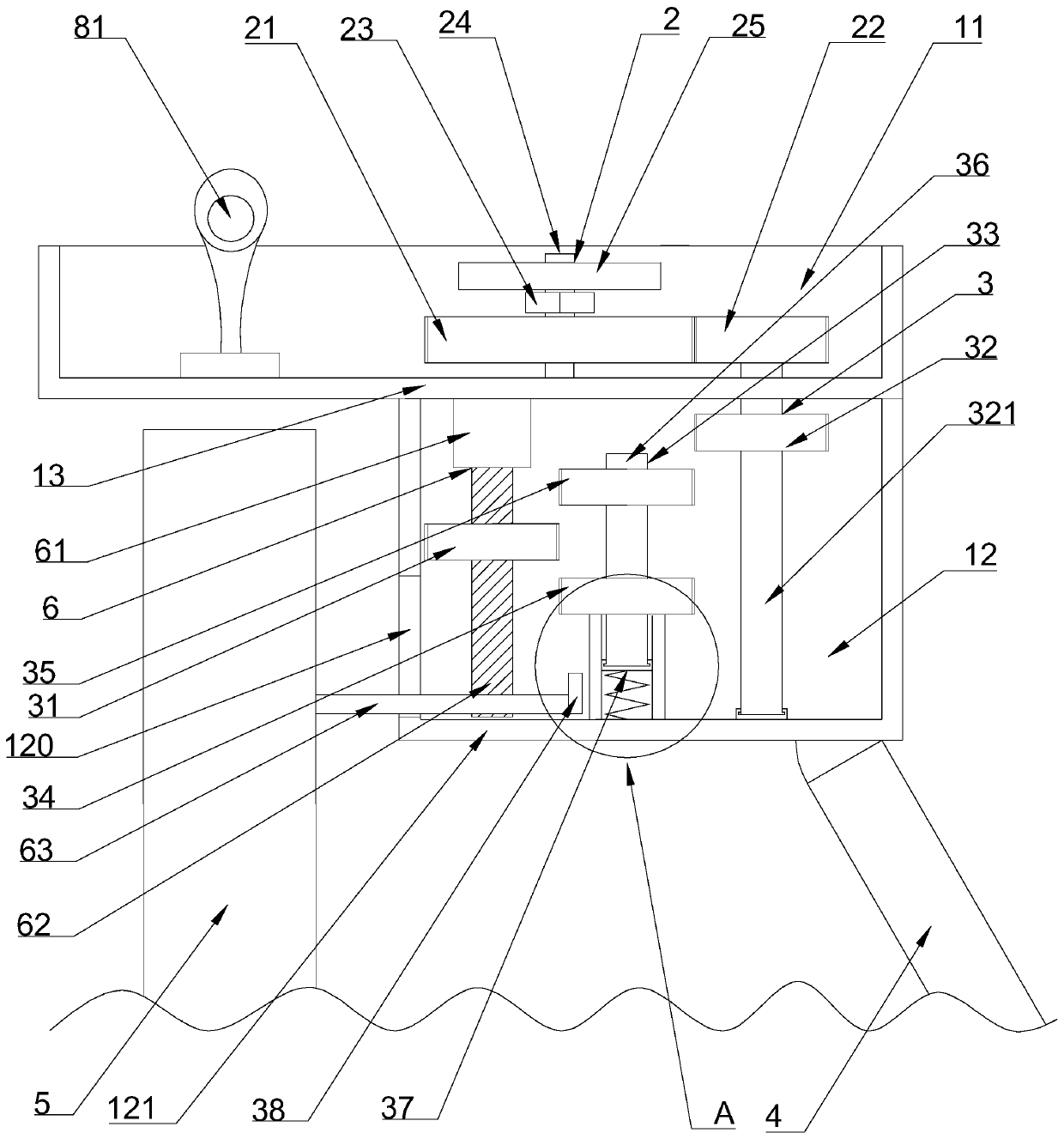

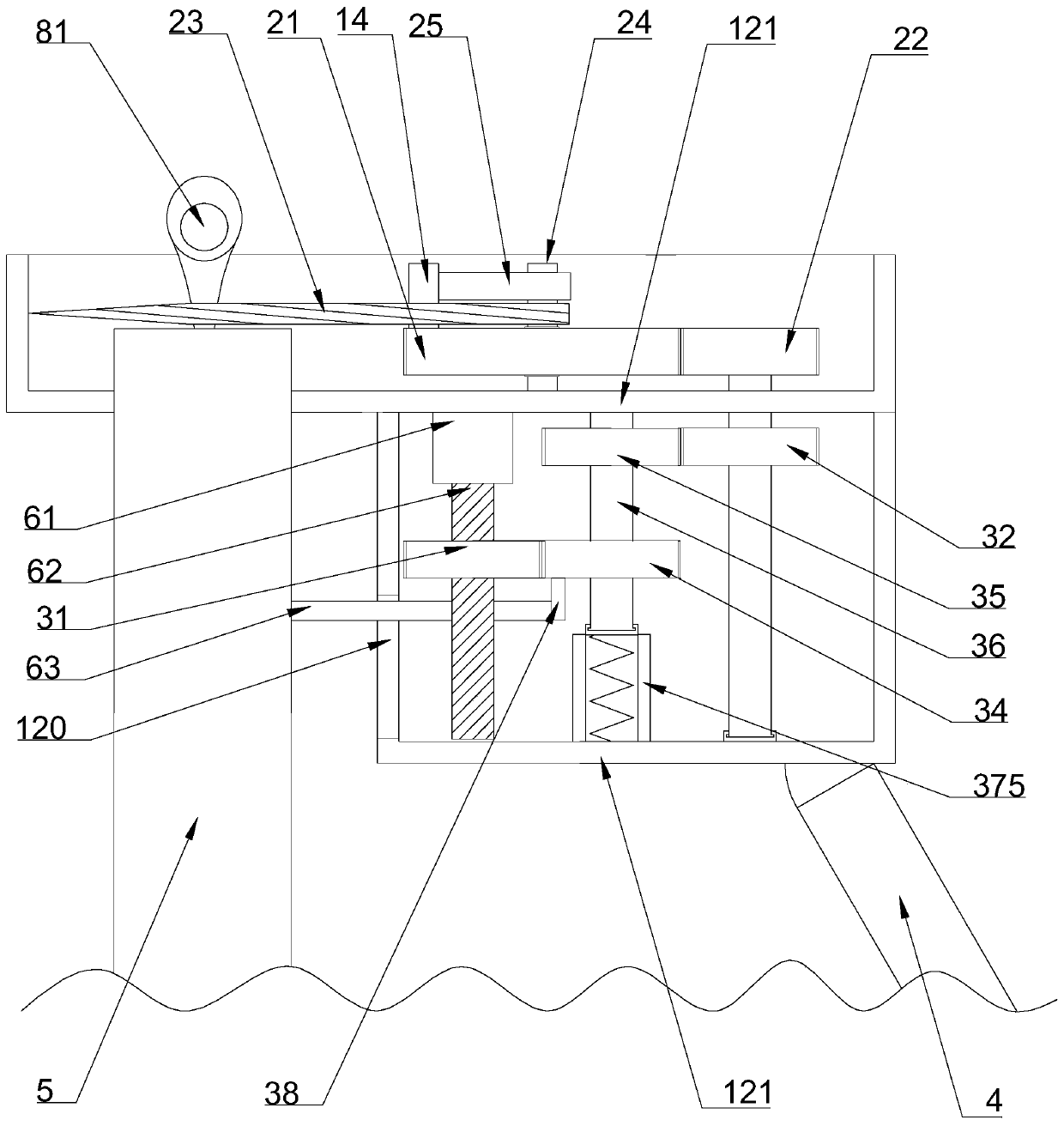

[0026] As an improved specific embodiment, the drive mechanism 3 includes a first pulley 31, a second pulley 32, and a transmission assembly 33, and the first pulley 31 is fixedly sleeved on the output shaft 62 of the rotating motor 61. The second pulley 32 includes a rotating shaft 321 arranged on the axis of the second pulley 32. The lower chamber 12 has a bottom plate 121. One end of the rotating shaft 321 is connected to the bottom plate 121, and the other end passes through the partition plate 13 to connect to the bottom plate 121. On the axis of the irregular gear 22, the transmission assembly 33 includes a first adjustment wheel 34, a second adjustment wheel 35, a vertical rod 36, and an elastic assembly 37, and the first adjustment wheel 34 and the second adjustment wheel 35 are the same The axis is fixedly sleeved on the vertical rod 36, the first adjustment wheel 34 is located on the side of the second adjustment wheel 35 facing away from the partition 13, one end of ...

Embodiment approach

[0028] As an improved specific embodiment, the elastic assembly 37 includes a connecting plate 371 and a spring 372 , the connecting plate 371 is provided with a slot 373 on one side facing the partition 13 , and one end of the vertical rod 36 facing the bottom plate 121 There is a protrusion 374 embedded in the slot 373, one end of the spring 372 is connected to the bottom plate 121, and the other end is connected to the side of the connecting plate 371 facing away from the slot 373, the spring 372 is used to keep the transmission assembly 33 back Move to partition 13.

[0029] Through the above technical scheme: by setting the slot 373 on the connecting plate 371 and the projection 374 on the vertical bar 36, the vertical bar 36 can be connected to the connecting plate 371, and the vertical bar 36 can rotate in the slot 373 , when the lifting plate 63 on the rotating motor 61 moves toward the bottom plate 121, and when the conflicting rod 38 is separated from the first adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com