Impurity removing method of sticky rice

A technology for removing impurities and glutinous rice, applied in application, grain processing, grain milling, etc., can solve the problems of excessive heavy metals in glutinous rice, heavy metal pollution, etc., and achieve the effect of ensuring cleanliness and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

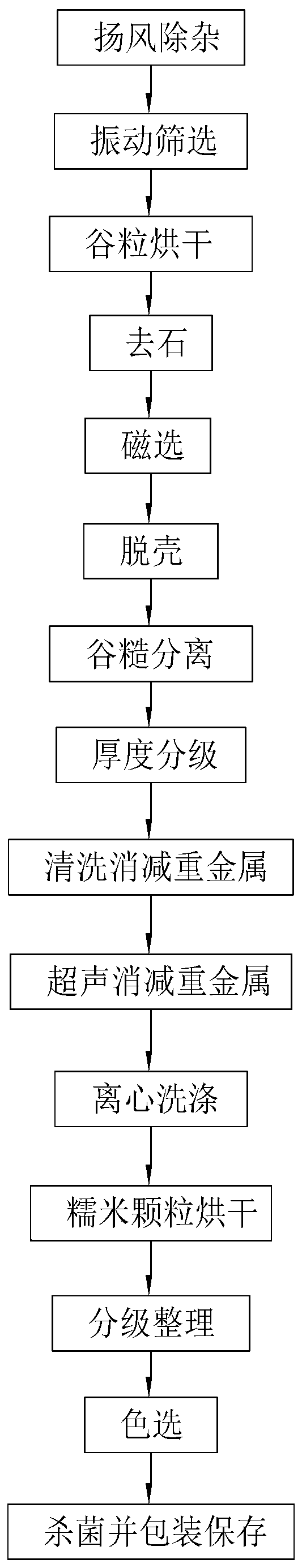

[0031] Such as figure 1 As shown, a method for removing impurities from glutinous rice comprises the following method steps:

[0032] Step 1, passing the threshed paddy through a fan to remove weeds and dust;

[0033] Step 2: Preliminary screening of the paddy after blowing the wind with a vibrating sieve to remove large debris;

[0034] Step 3, sending the rice after preliminary screening into the dryer for drying treatment;

[0035] Step 4, the dried rice is sent to the de-stoner to remove gravel;

[0036] Step 5, the stone-removed rice passes through the permanent magnet cylinder of the magnetic separator to remove the metal substances in it to ensure the quality of glutinous rice;

[0037] Step 6, transporting the magnetically separated ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com