Concrete curing box test block placing assembly and mounting structure

A curing box and concrete technology, which is applied to the field of placing components and installation structures of test blocks in concrete curing boxes, can solve the problems of inability to guarantee the stable placement state of test blocks, unable to meet the needs of diversified test blocks, etc., so as to improve the use value and convenience. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

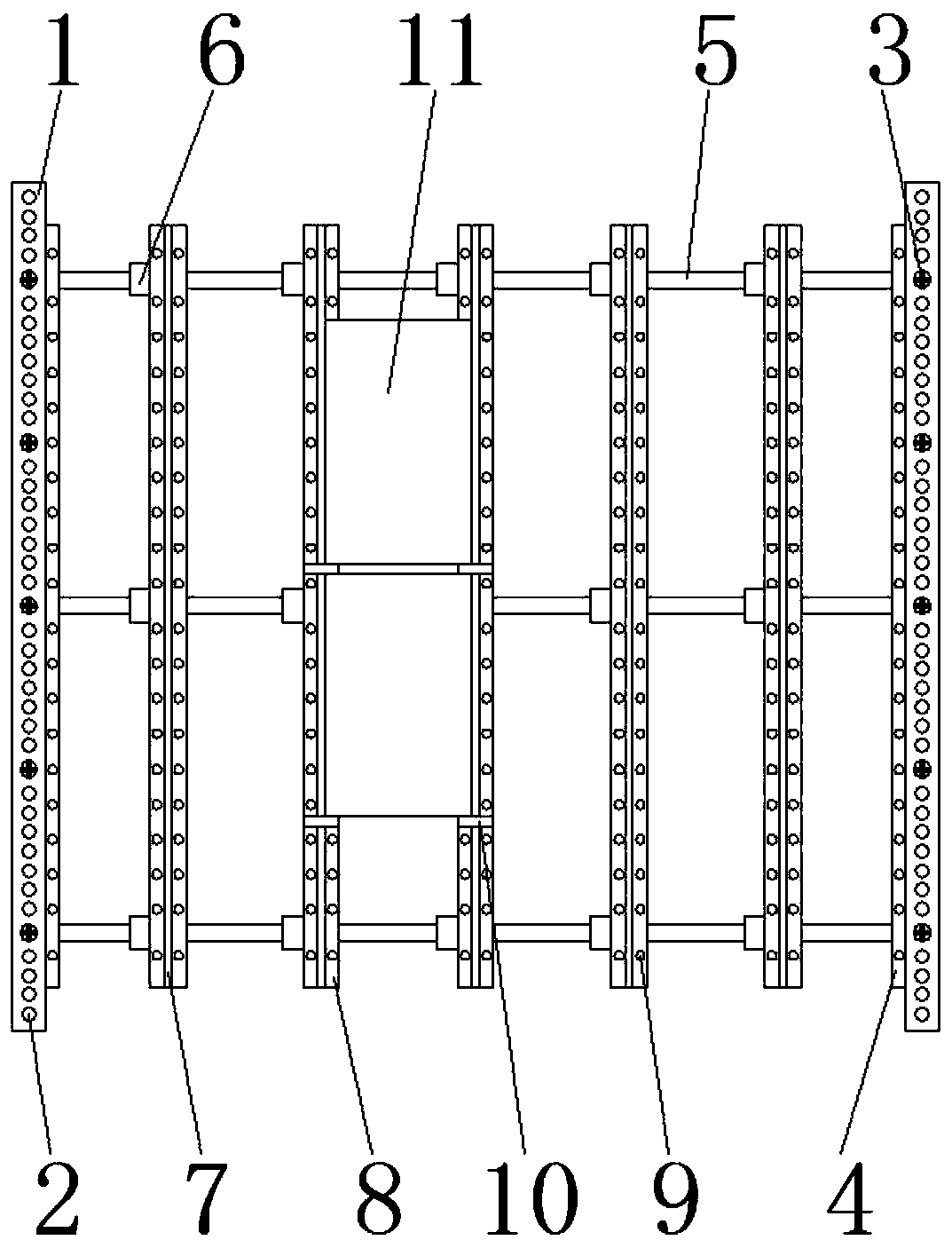

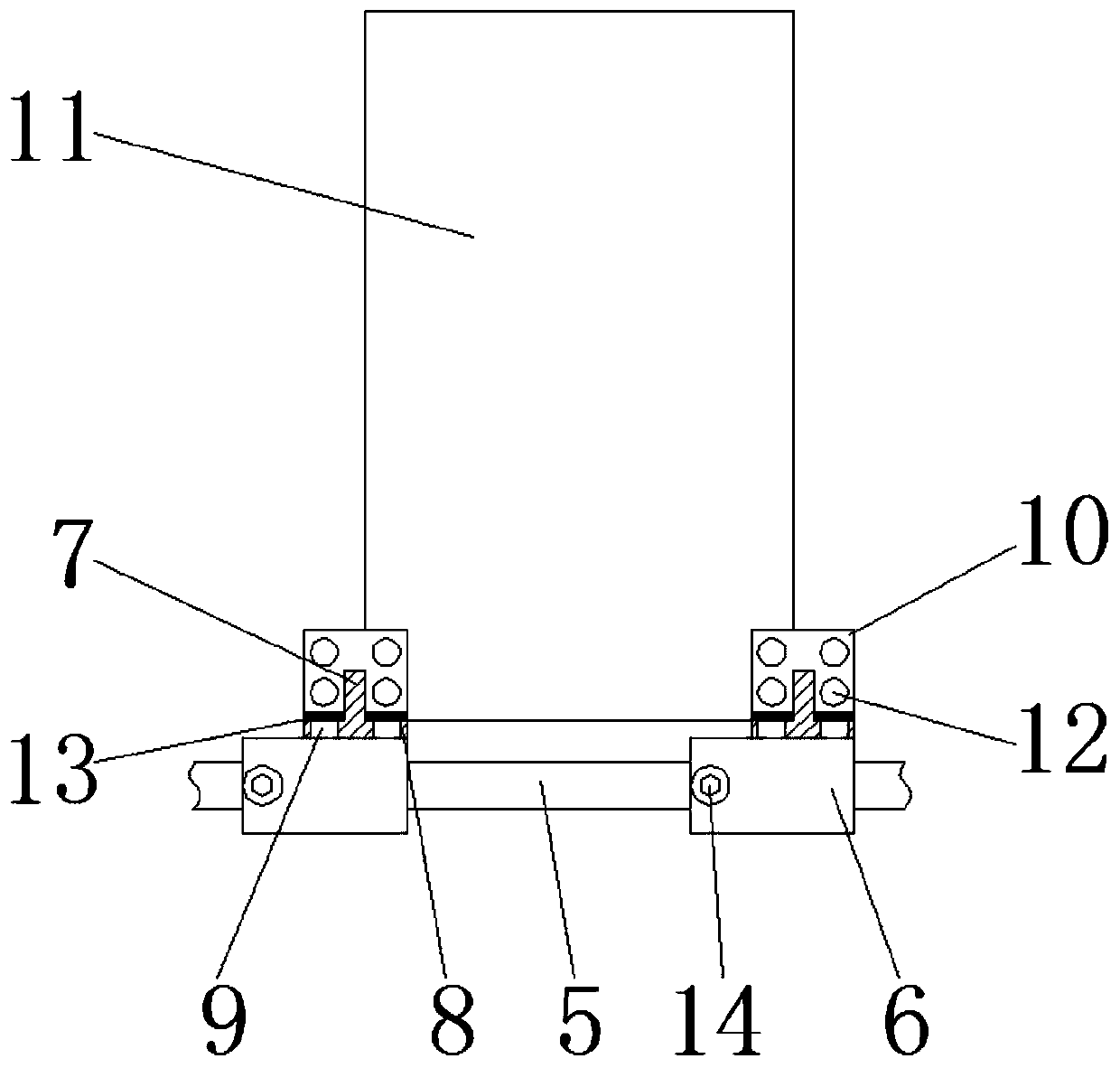

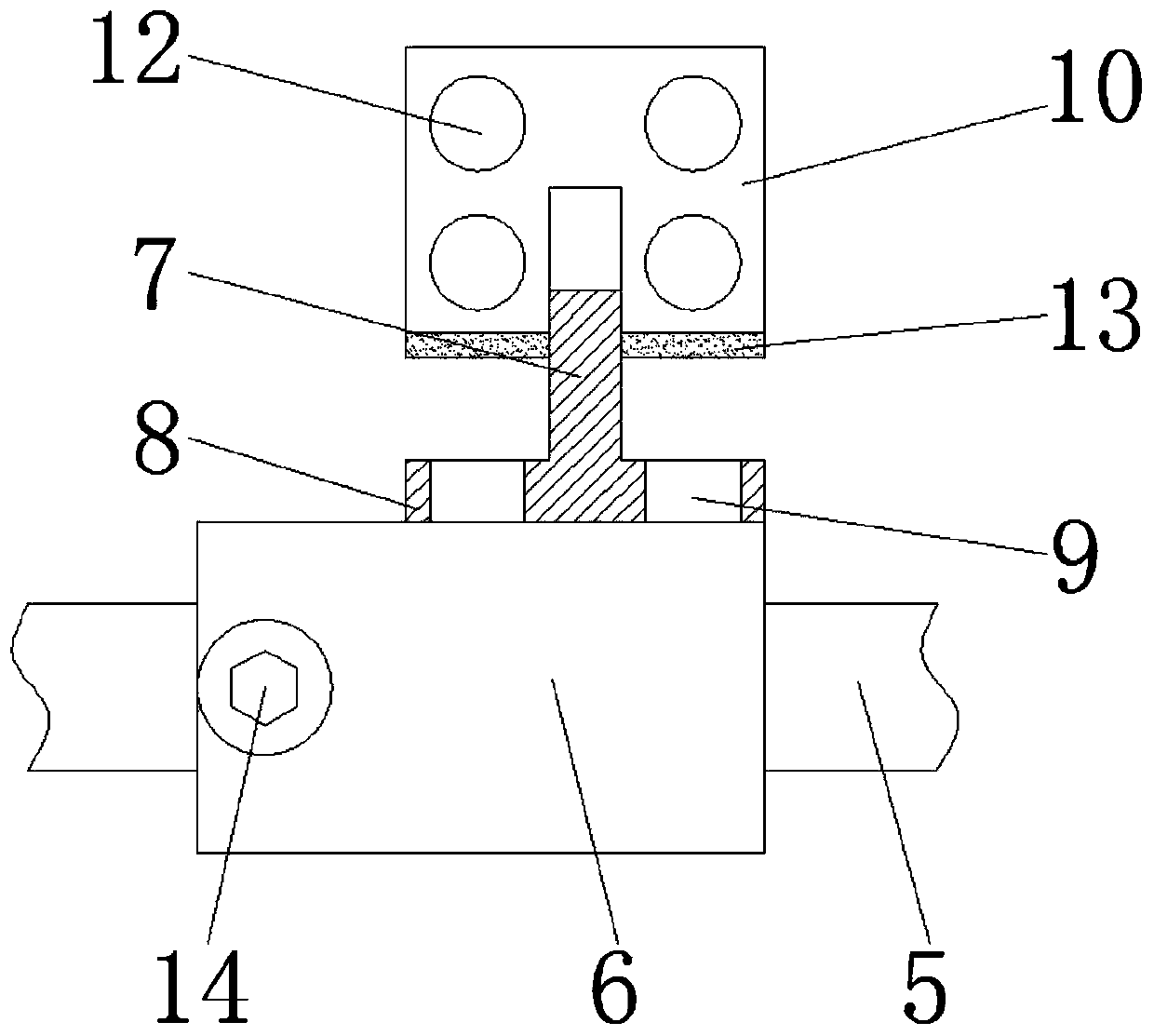

[0030] see Figure 1-7 , a concrete curing box test block placement assembly of the present embodiment, including a limit piece 1, a ball 2, a first fixing bolt 3, a first support piece 4, a support rod 5, a connecting seat 6, a first spacer 7, The second support piece 8, the first through hole 9, the second spacer 10, the concrete test block 11, the second through hole 12, the magnet piece 13, the second fixing bolt 14, the third through hole 15, the sliding support body 16, The fourth through hole 17 and the fixing groove 18, the lower side of the limiting piece 1 is connected with a sliding support body 16, and a ball 2 is arranged between the sliding supporting body 16 and the limiting piece 1, the limiting piece 1 and the sliding supporting body 16 The first support piece 4 and the support rod 5 are fixed on the inner side of the sliding support body 16, and the support rod 5 is located on the lower side of the first support piece 4, and the support rod 5 is connected wit...

Embodiment 2

[0039] see Figure 1-7 , a concrete curing box test block installation structure of the present embodiment, including a limit piece 1, a ball 2, a first fixing bolt 3, a first support piece 4, a support rod 5, a connecting seat 6, a first spacer 7, The second support piece 8, the first through hole 9, the second spacer 10, the concrete test block 11, the second through hole 12, the magnet piece 13, the second fixing bolt 14, the third through hole 15, the sliding support body 16, The fourth through hole 17 and the fixing groove 18, when using the concrete curing box to place the concrete test block 11, it is necessary to install the placement structure of the concrete test block 11 in the concrete curing box to facilitate the placement of the concrete test block 11 First, the ball 2 needs to be placed between the limiting piece 1 and the sliding support body 16, and then the limiting piece 1 and the sliding supporting body 16 are fixed together by the first fixing bolt 3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com