Shipping methods for centrifugal compressors

A centrifugal compressor, packaging box technology, applied in the direction of machine containers, packaging food, assembling machines, etc., can solve problems such as packaging box damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

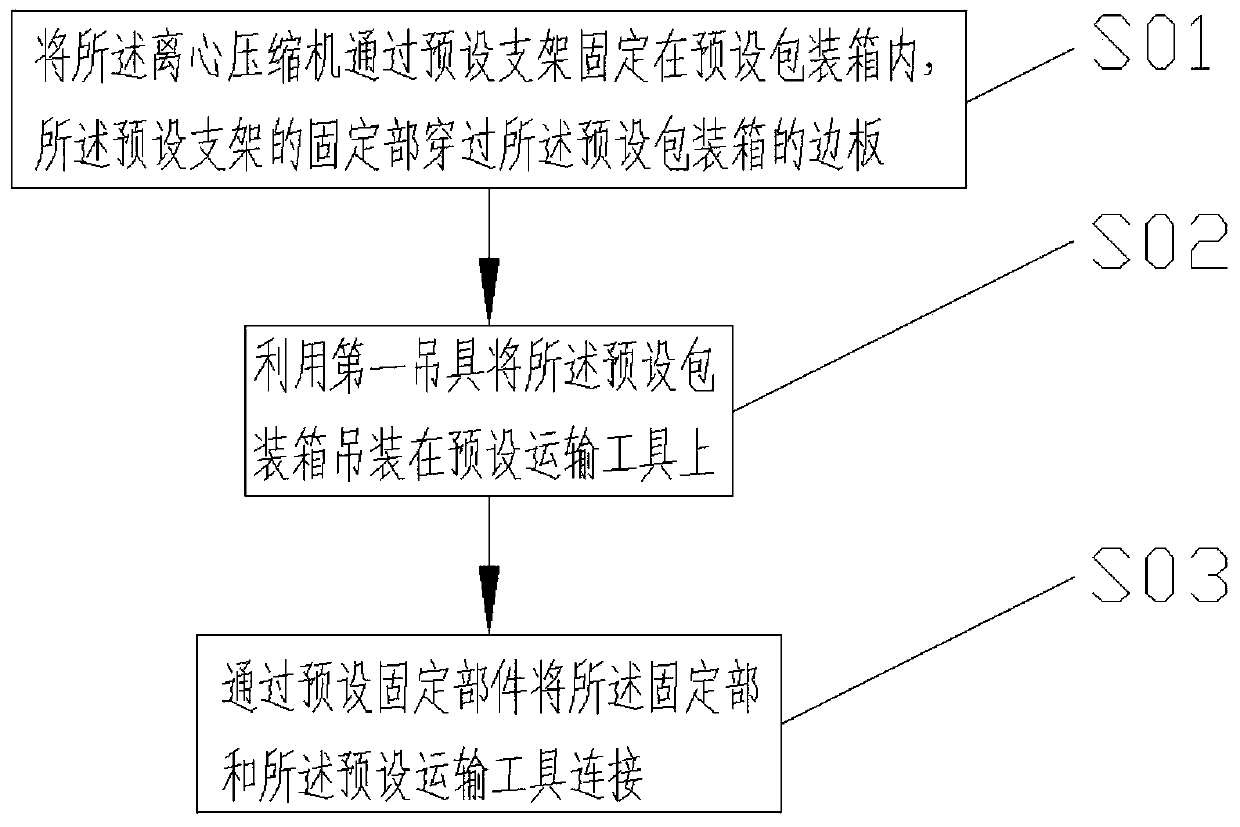

[0058] see figure 1 , in order to solve the technical problem that the centrifugal compressor is packaged in the prior art packaging box, and the packaging box is prone to damage during hoisting or transportation, the present invention provides a packaging method for the centrifugal compressor, including:

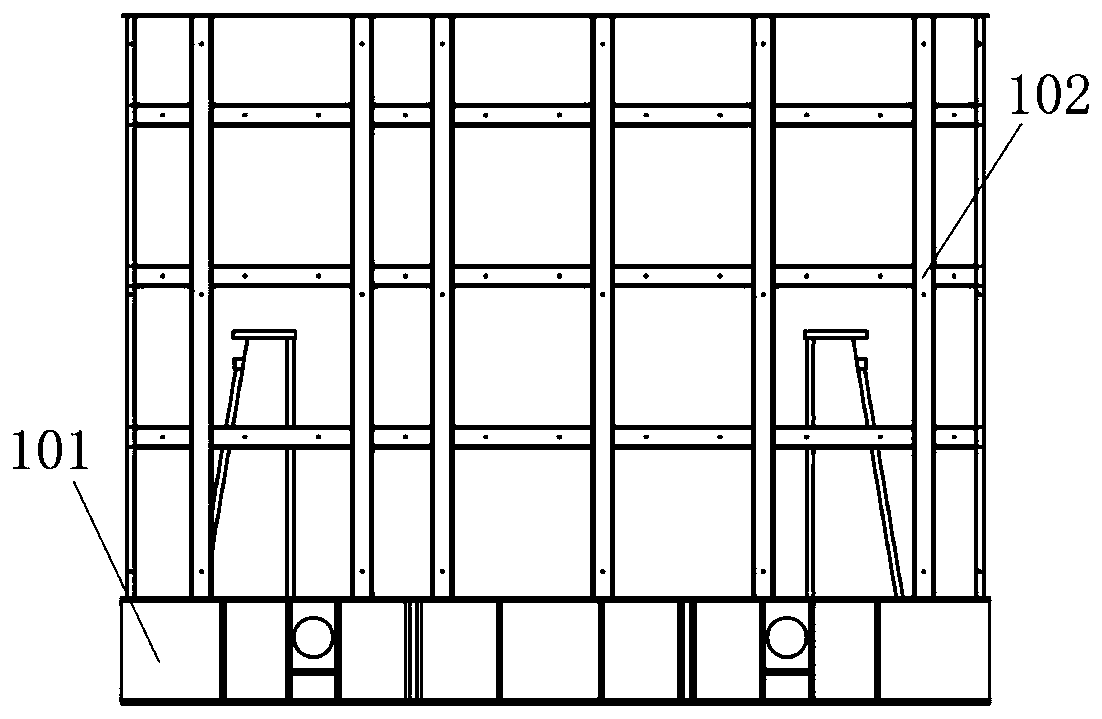

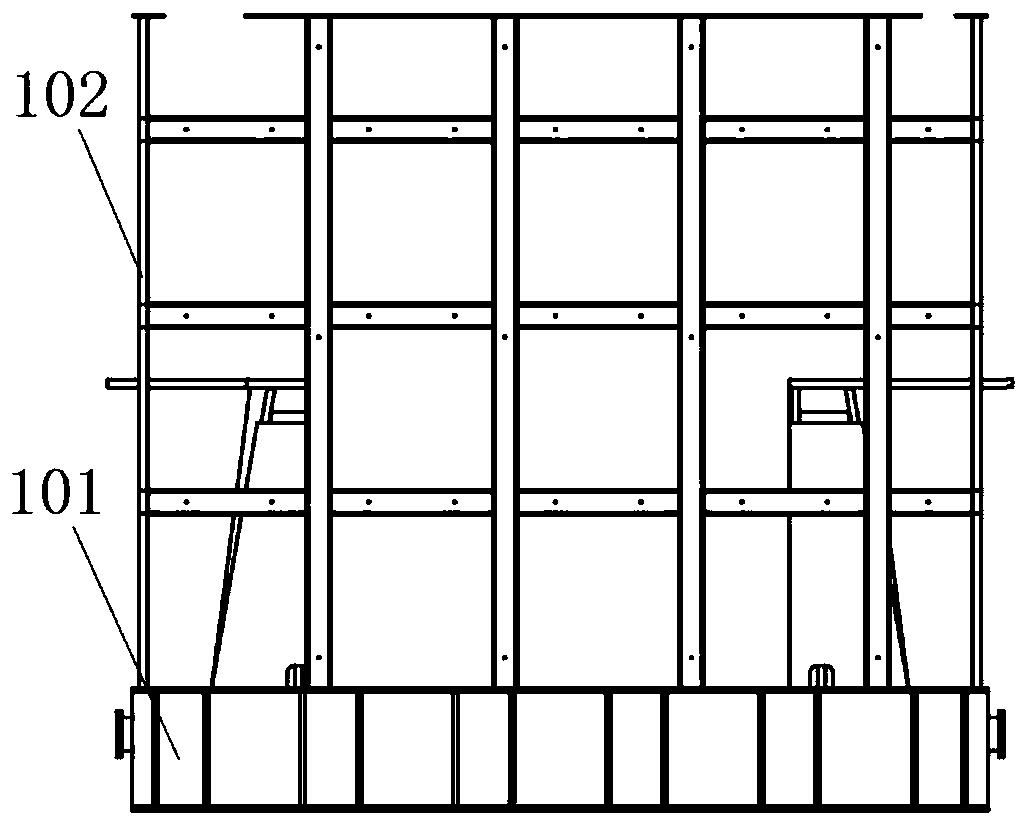

[0059] S01: Fix the centrifugal compressor in the preset packing box through the preset bracket, and the fixed part of the preset bracket passes through the side plate of the preset packing box. Wherein, the preset bracket should be made according to the volume and weight of the centrifugal compressor, and the size of the preset packing box and the size of the centrifugal compressor. When the centrifugal compressor is fixed on the base of the preset packing box through the preset bracket, the lower half of the casing of the centrifugal compressor should be able to be accommodated in the space surrounded by multiple preset brackets, thereby reducing the centrifugal compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com