Sewing method of fancy stitch seam and electronic sawtooth sewing machine

A sewing machine and stitch technology, which are applied to the sewing method of fancy stitch seams and the field of electronic sawtooth sewing machines, can solve the problems of wrong spacing and pattern breakage, and achieve the effect of solving pattern breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

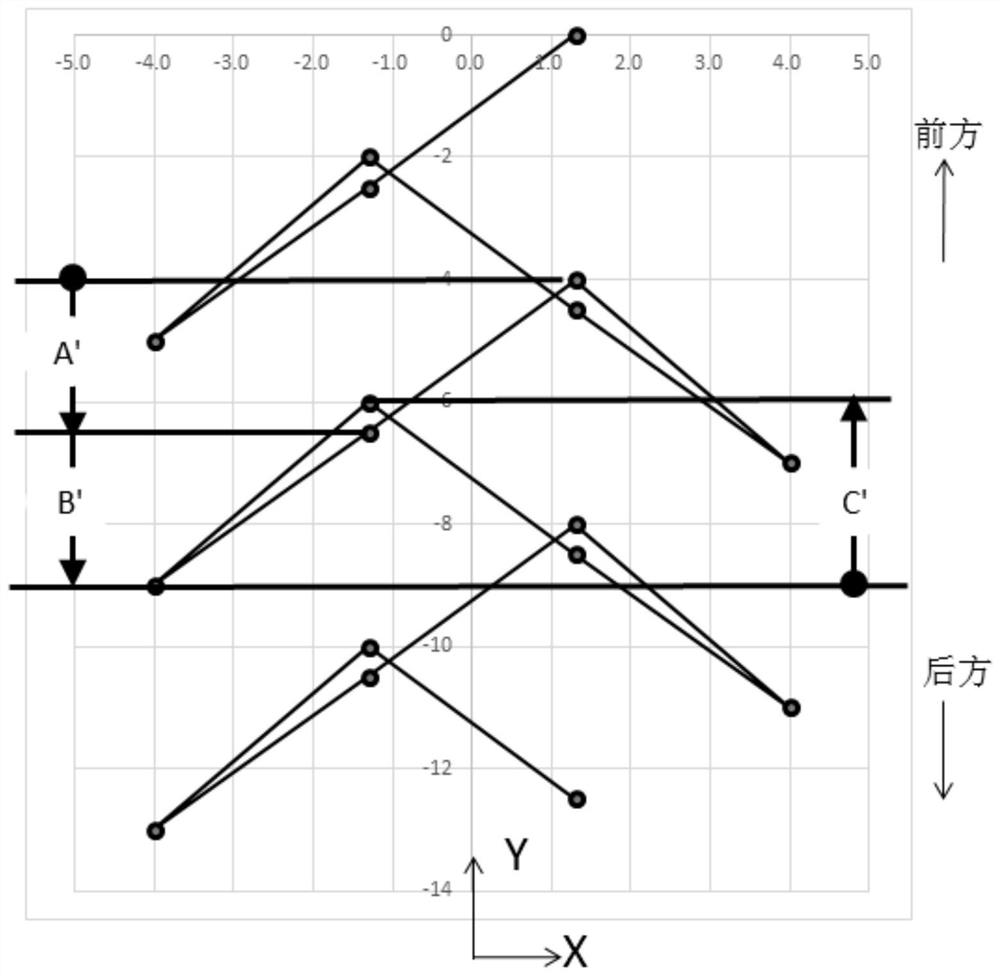

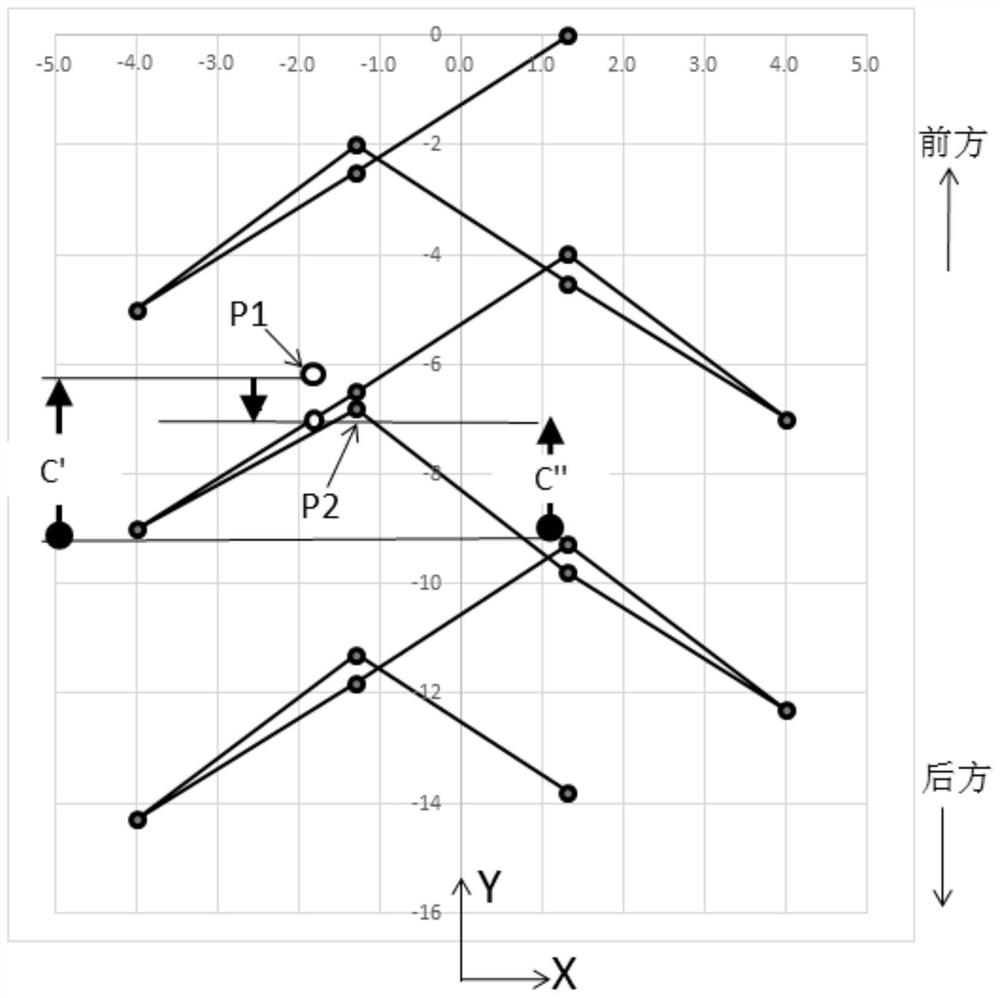

[0039] The present invention will be further described below with reference to the accompanying drawings.

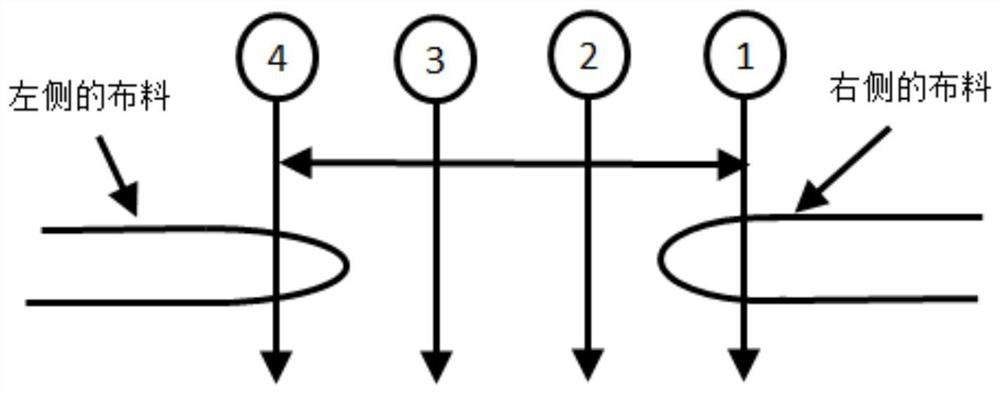

[0040] According to a first aspect of the present invention, the present invention provides a method for sewing fancy stitch seams using fabrics capable of changing and adjusting the pitch of the fed fabrics on a stitch-by-needle (stitch) basis A fancy stitch sewing method used in an electronic zigzag sewing machine that forms stitches on a cloth by cooperating with a feeding device and a needle oscillating mechanism that oscillates the needle in a direction intersecting the feeding direction of the cloth.

[0041] First, the direction of the present invention is defined. It can be understood that the definitions of these directions are only used to understand the present invention and should not limit the present invention.

[0042] The above cloth feeding direction is Figure 5 Y-axis direction shown. More specifically, along Figure 5 The positive Y-axis direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com