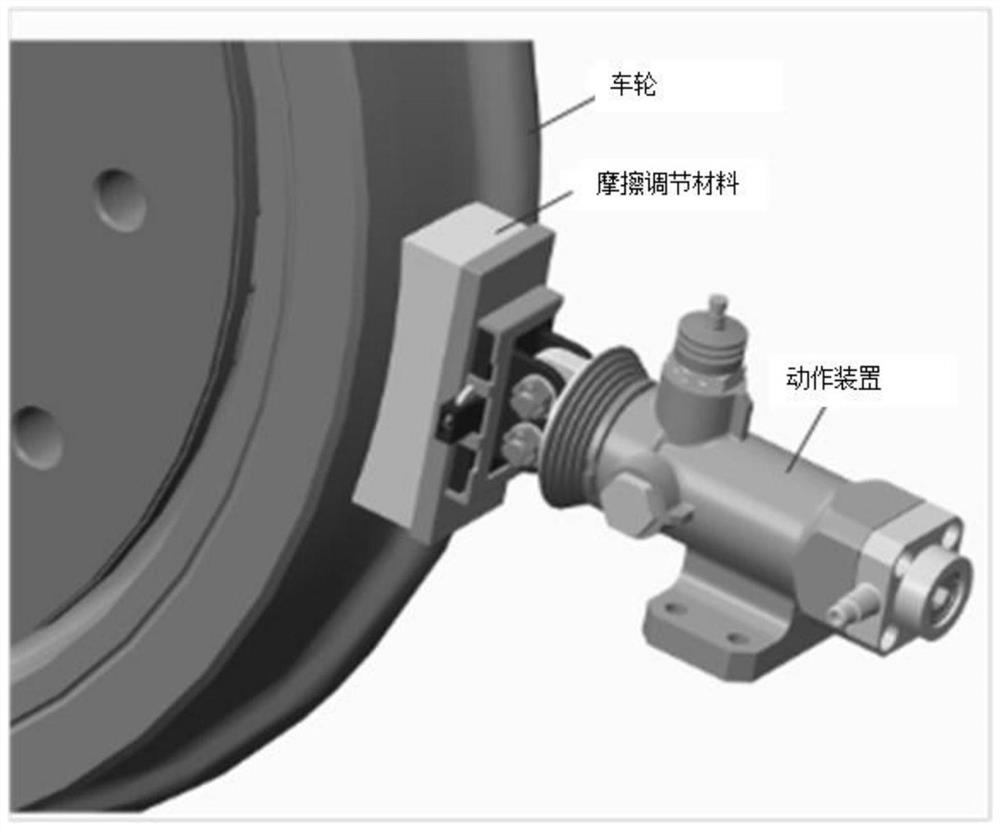

Wheel-rail friction adjusting material and preparation method thereof

A wheel-rail and friction coefficient technology, applied in the field of rail transit, can solve problems such as limiting the service life of solid wheel-rail tread friction agents, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a formula for preparing the wheel-rail friction regulating material, and the product is mainly used on heavy-duty trains with larger axle loads, providing a coefficient of friction of 0.3-0.4, and its product components are: polytetrafluoroethylene The mass fraction is 25, the mass fraction of graphite is 35, the mass fraction of silicon dioxide is 14, the mass fraction of phenolic formaldehyde is 18, and the mass fraction of paraffin is 8.

Embodiment 2

[0050] The present embodiment provides a kind of formula for preparing wheel-rail friction regulating material, and this product is mainly used in traditional passenger car and train set, provides the coefficient of friction of 0.25-0.35, and its product component is: polytetrafluoroethylene mass parts 34, the mass fraction of graphite is 34, the mass fraction of silicon dioxide is 10, the mass fraction of phenolic formaldehyde is 16, and the mass fraction of paraffin wax is 6.

Embodiment 3

[0052] The present embodiment provides a kind of formula for preparing wheel-rail friction regulating material, and this product is mainly used on the subway train, provides the coefficient of friction of 0.2-0.3, and its product component is: polytetrafluoroethylene mass fraction is 40, The mass fraction of graphite is 30, the mass fraction of silicon dioxide is 15, the mass fraction of phenolic formaldehyde is 12, and the mass fraction of paraffin is 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap