Two-axis orthogonal rotation system and method for CVD equipment

A kind of technology of equipment and rotating shaft, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of poor deposition quality and stability of epitaxial layer, and cannot be effectively controlled, so as to improve coating quality and production Efficiency, improvement of flow velocity distribution, and effect of improving CVD efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

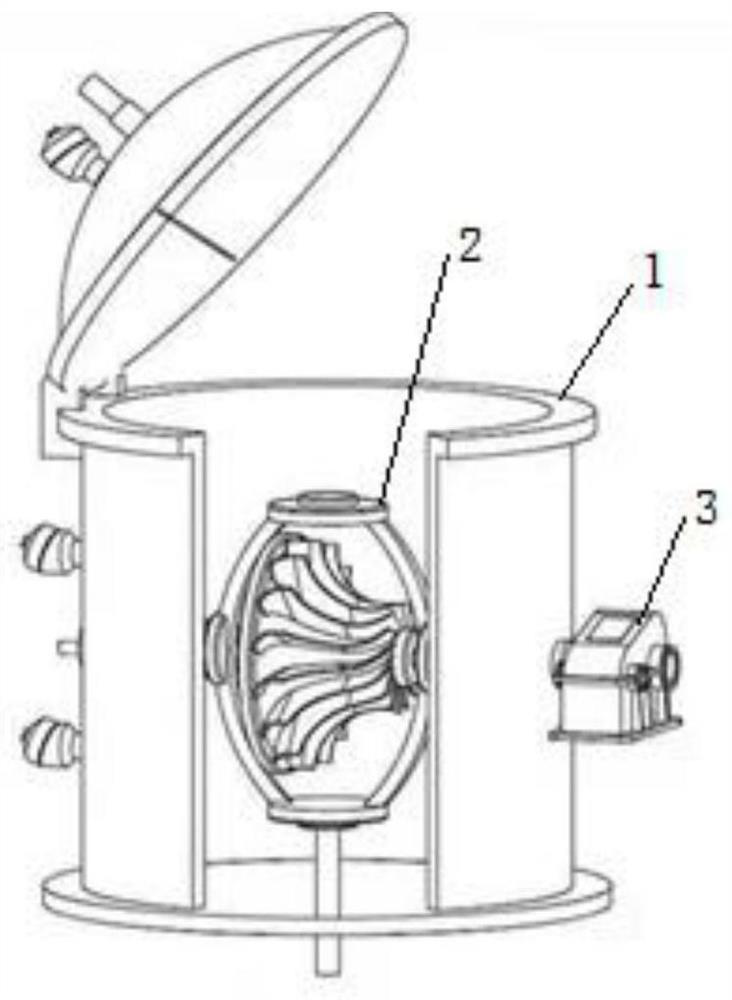

[0042] refer to figure 1 , 2 and 9, the central position of the constant temperature zone in the CVD deposition furnace body 1 is set as the coordinate origin, the xoy plane of the coordinates is perpendicular to the central axis of the constant temperature zone, and the z axis of the coordinates coincides with the central axis of the constant temperature zone; Three sleeves 13 pass through the CVD deposition furnace furnace body 1 and the graphite insulation pipe 11 along the positive and negative directions of the coordinate X axis and the negative direction of the Z axis respectively, and one end of the three sleeves 13 is connected to the CVD deposition furnace furnace body 1 respectively. Seamlessly welded, the other end is respectively fixed and sealed with the graphite insulation pipe 11, such as connected by threaded rotation;

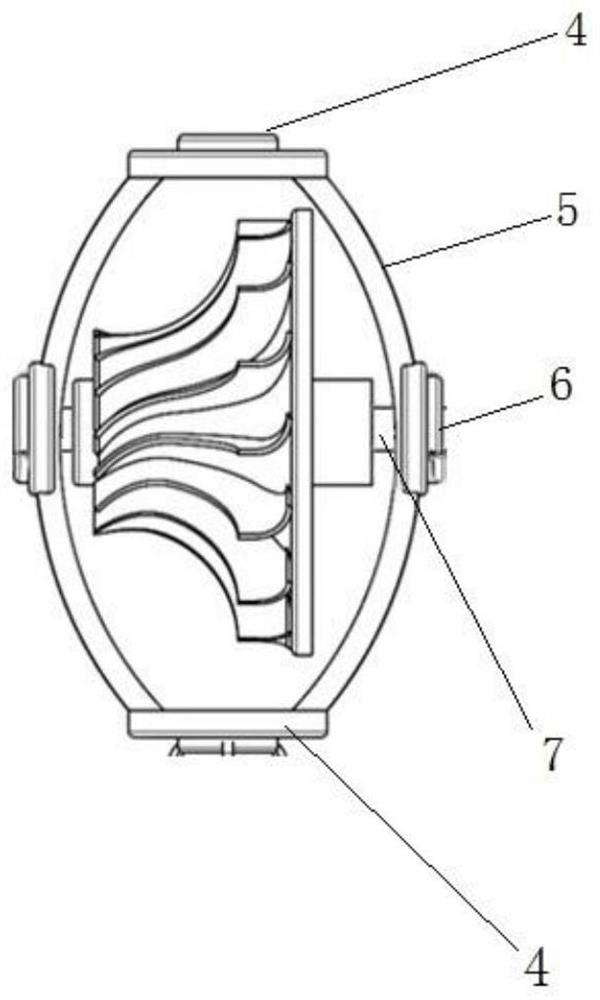

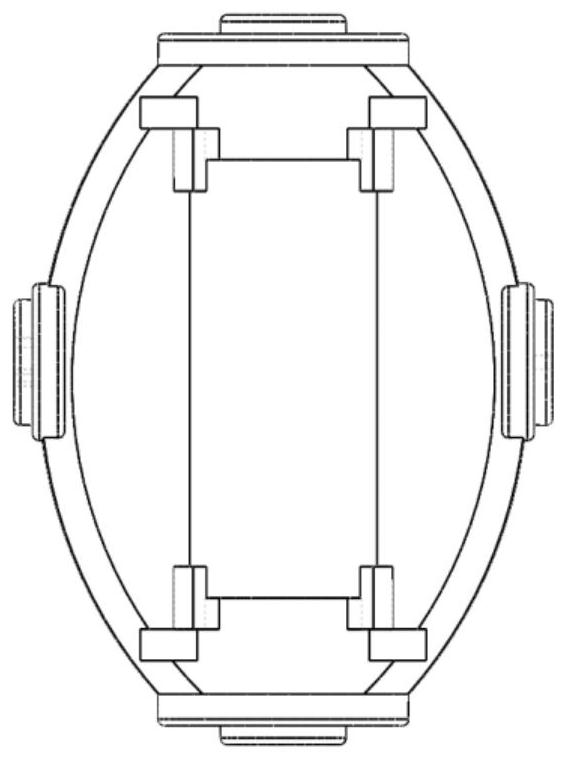

[0043] The component fixture 2 is a hollowed-out frame structure, which is used to fix and install the deposited component. The center point ...

Embodiment 2

[0045] refer to figure 1 , 3 and 9, the central position of the constant temperature zone in the CVD deposition furnace body 1 is set as the coordinate origin, the xoy plane of the coordinates is perpendicular to the central axis of the constant temperature zone, and the z axis of the coordinates coincides with the central axis of the constant temperature zone; Three sleeves 13 pass through the CVD deposition furnace furnace body 1 and the graphite insulation pipe 11 along the positive and negative directions of the coordinate X axis and the negative direction of the Z axis respectively, and one end of the three sleeves 13 is connected to the CVD deposition furnace furnace body 1 respectively. Seamlessly welded, the other end is respectively fixed and sealed with the graphite insulation pipe 11, such as connected by threaded rotation;

[0046] The component fixture 2 is a hollowed-out frame structure, which is used to fix and install the deposited component. The center point ...

Embodiment 3

[0049] refer to figure 1 , 5 and 9, the central position of the constant temperature zone in the CVD deposition furnace body 1 is set as the coordinate origin, the xoy plane of the coordinates is perpendicular to the central axis of the constant temperature zone, and the z axis of the coordinates coincides with the central axis of the constant temperature zone; Three sleeves 13 pass through the CVD deposition furnace furnace body 1 and the graphite insulation pipe 11 along the positive and negative directions of the coordinate X axis and the negative direction of the Z axis respectively, and one end of the three sleeves 13 is connected to the CVD deposition furnace furnace body 1 respectively. Seamlessly welded, the other end is respectively fixed and sealed with the graphite insulation pipe 11, such as connected by threaded rotation;

[0050] The component fixture 2 is a hollowed-out frame structure, which is used to fix and install the deposited component. The center point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com