Transformer oil pillow realizing replacement of vent hole resistance through rotation

A technology of transformer oil and air outlet, which is applied in the field of transformer oil conservator, which can solve the problems of deterioration of cooling oil, deterioration of cooling effect of transformer cooling oil, and reduction of cooling effect of transformer, so as to avoid oxidative deterioration and make it easy to rotate the outer ring layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

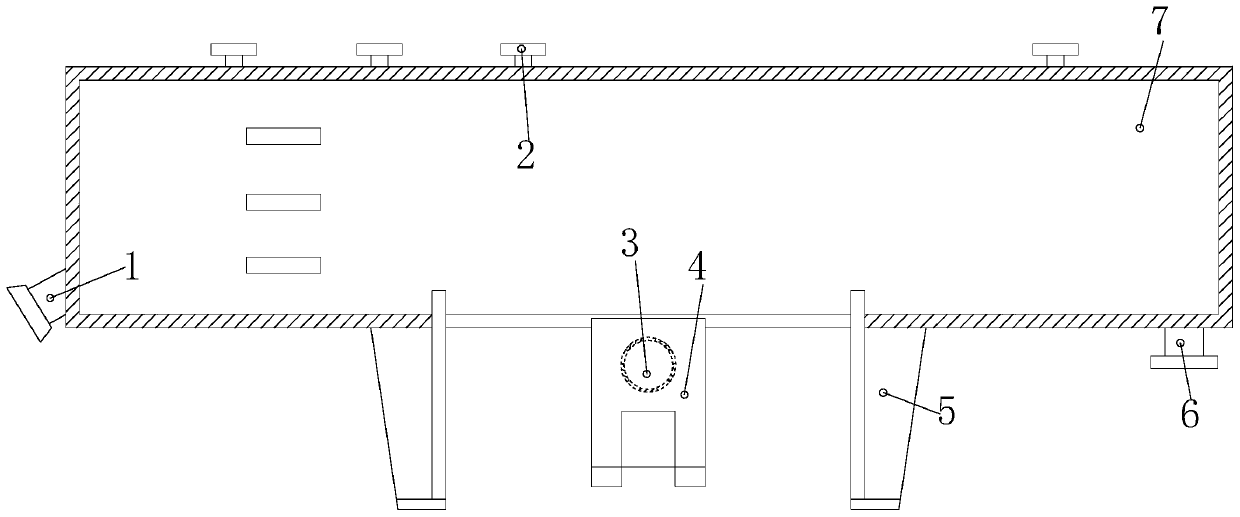

[0022] see Figure 1-Figure 3 , the present invention provides a transformer oil conservator that realizes the replacement of air outlet through rotation. Box 6 and shell 7, the pointer oil gauge 1 and the dirt collection box 6 are respectively installed on the two ends of the shell 7, the pointer oil gauge 1 and the dirt collection box 6 both run through the shell 7, the said The moisture absorber pipe joint 2 is arranged on the top of the casing 7, the gas collecting box 4 is installed in the center of the bottom of the casing 7, and the support feet 5 are provided with two symmetrical structures and arranged on the bottom of the casing 7. The support feet 5 is mechanically welded with the shell 7, and the gas collecting box 4 is provided with an oil conservator air outlet 3, and the oil conservator air outlet 3 communicates with the inner cavity of the shell 7.

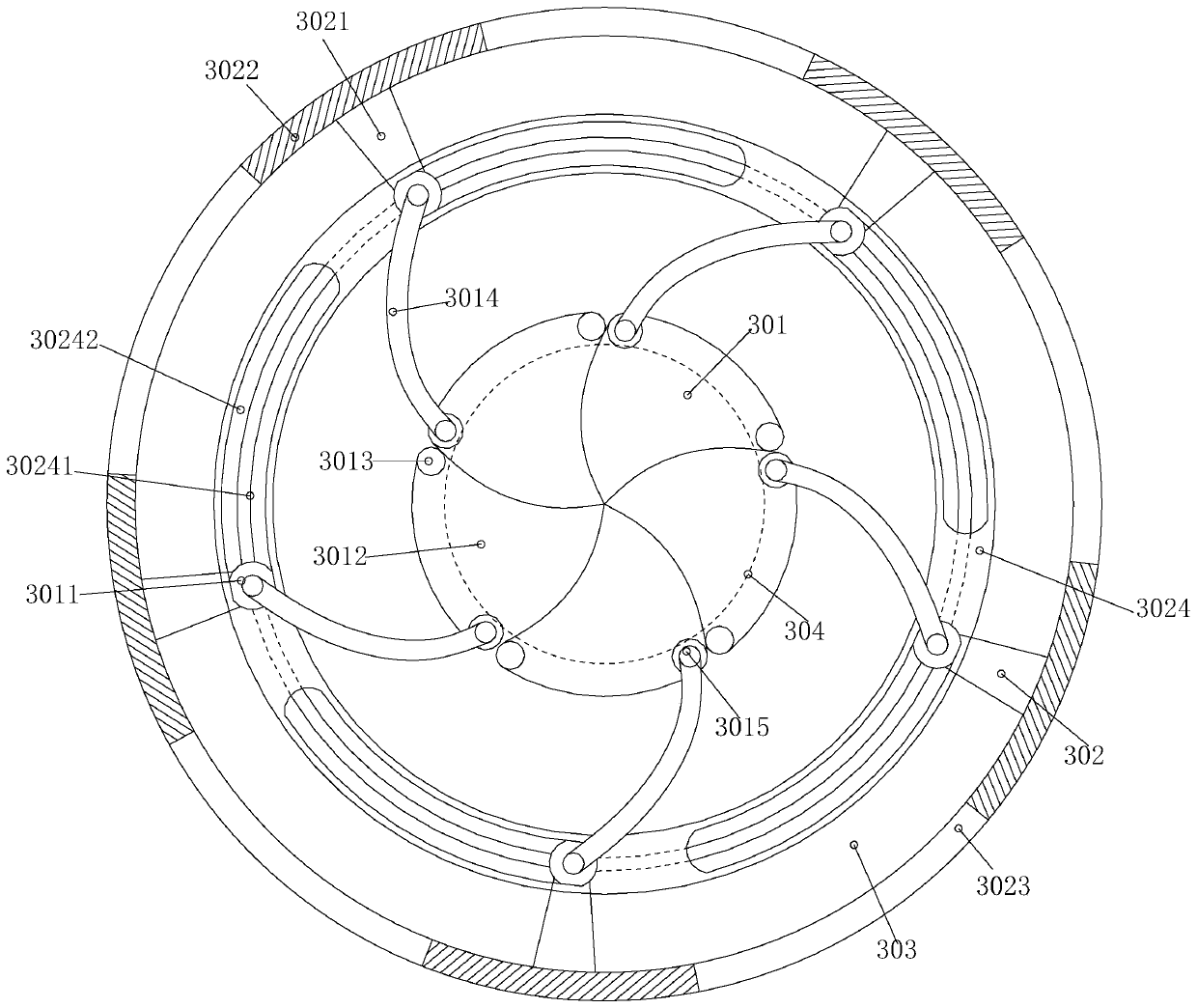

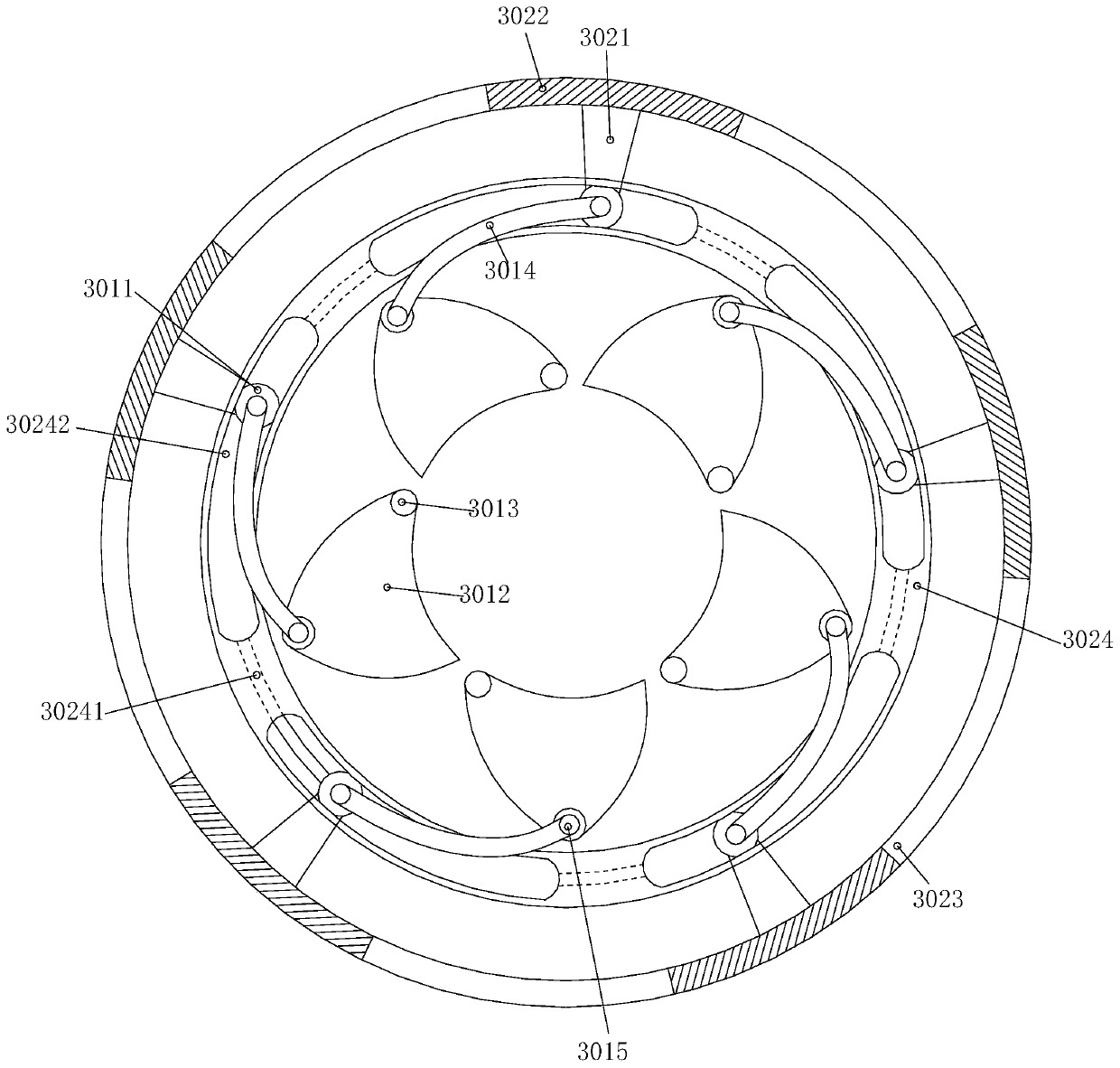

[0023] The air outlet hole 3 of the oil conservator is composed of a resistance mechanism 301, a driving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com