Mop cleaning barrel capable of isolating dirty water from clean water

A mop cleaning bucket, dirty water technology, applied in the field of cleaning buckets, can solve the problem of flat mop cleaning effect decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

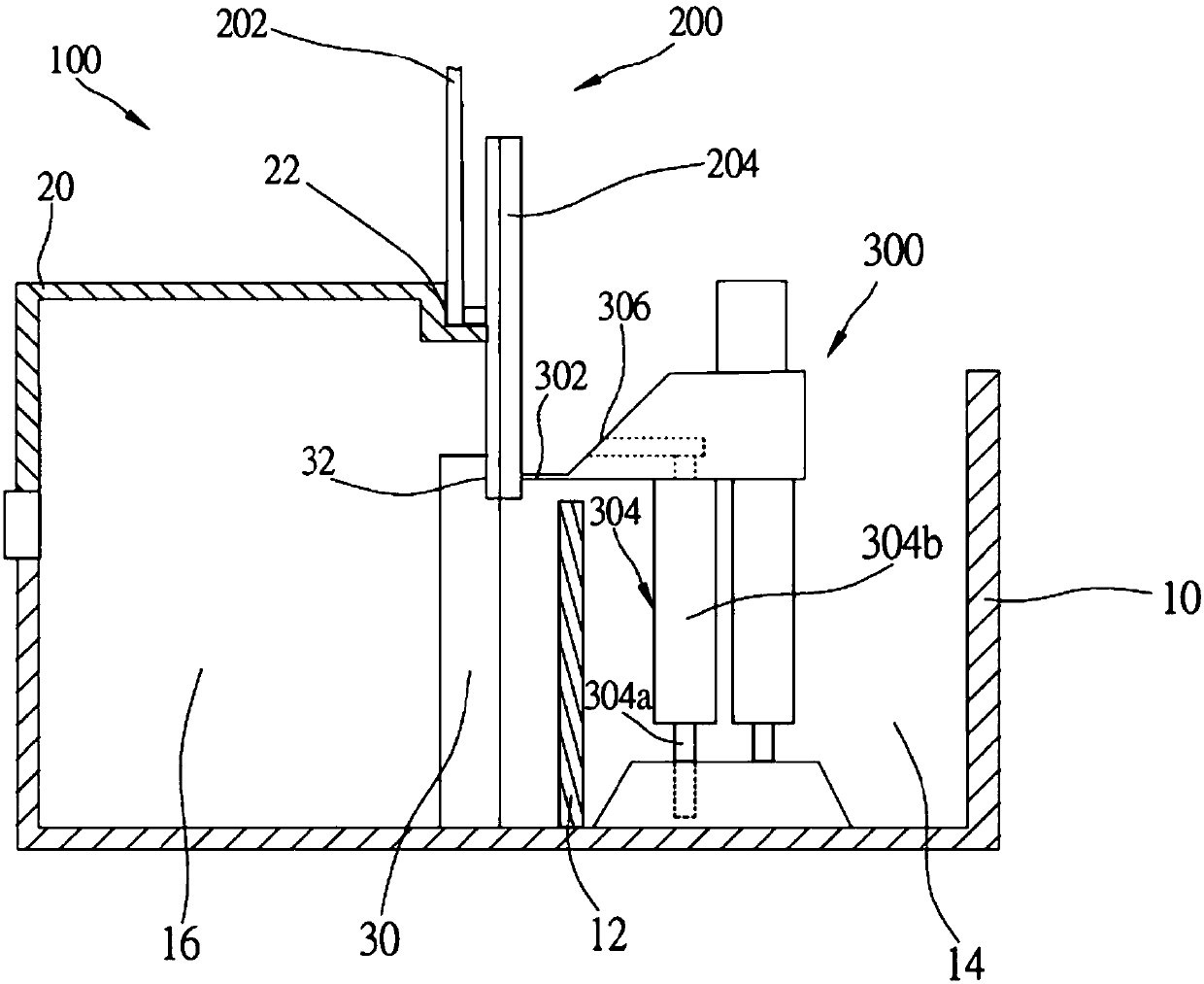

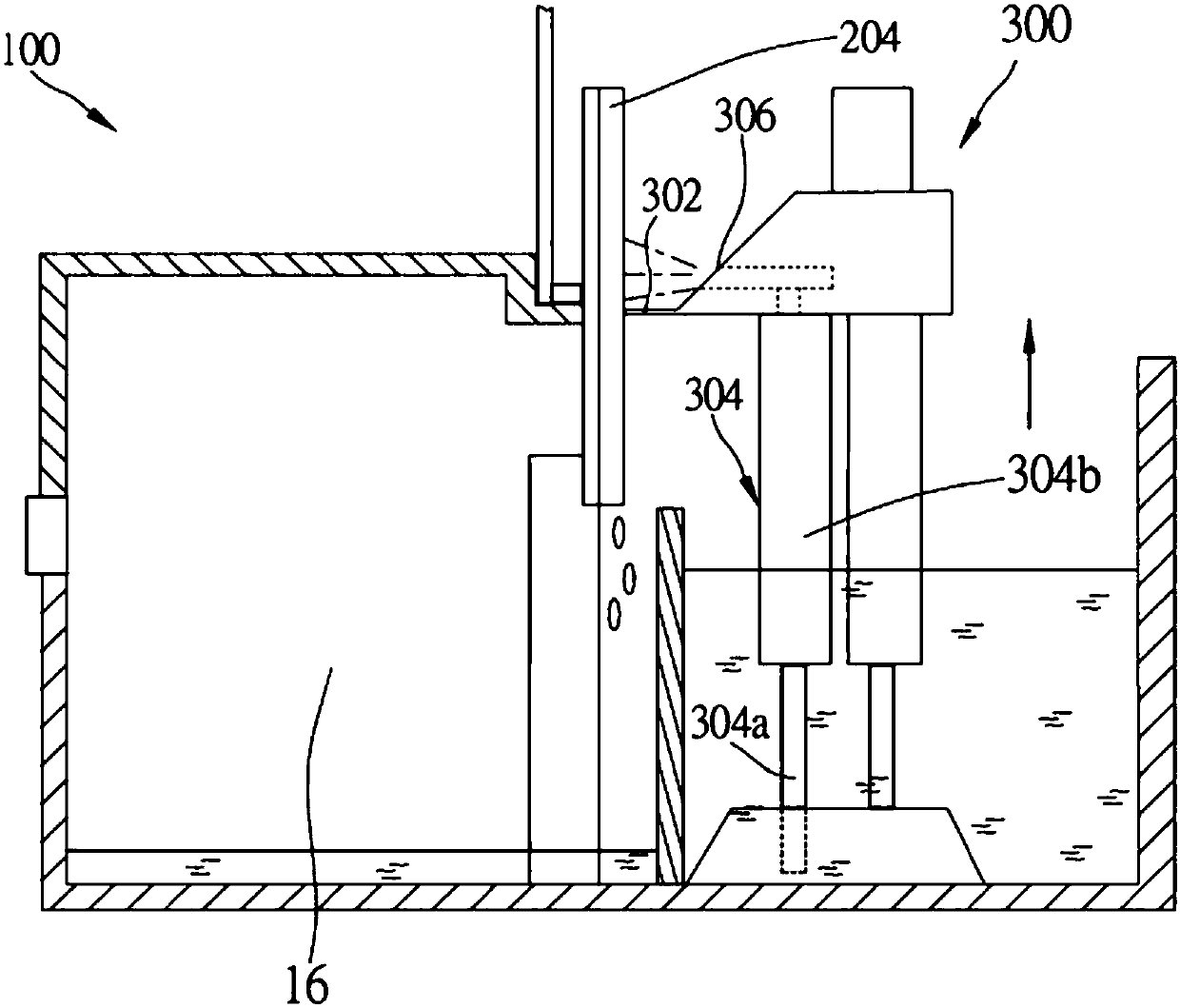

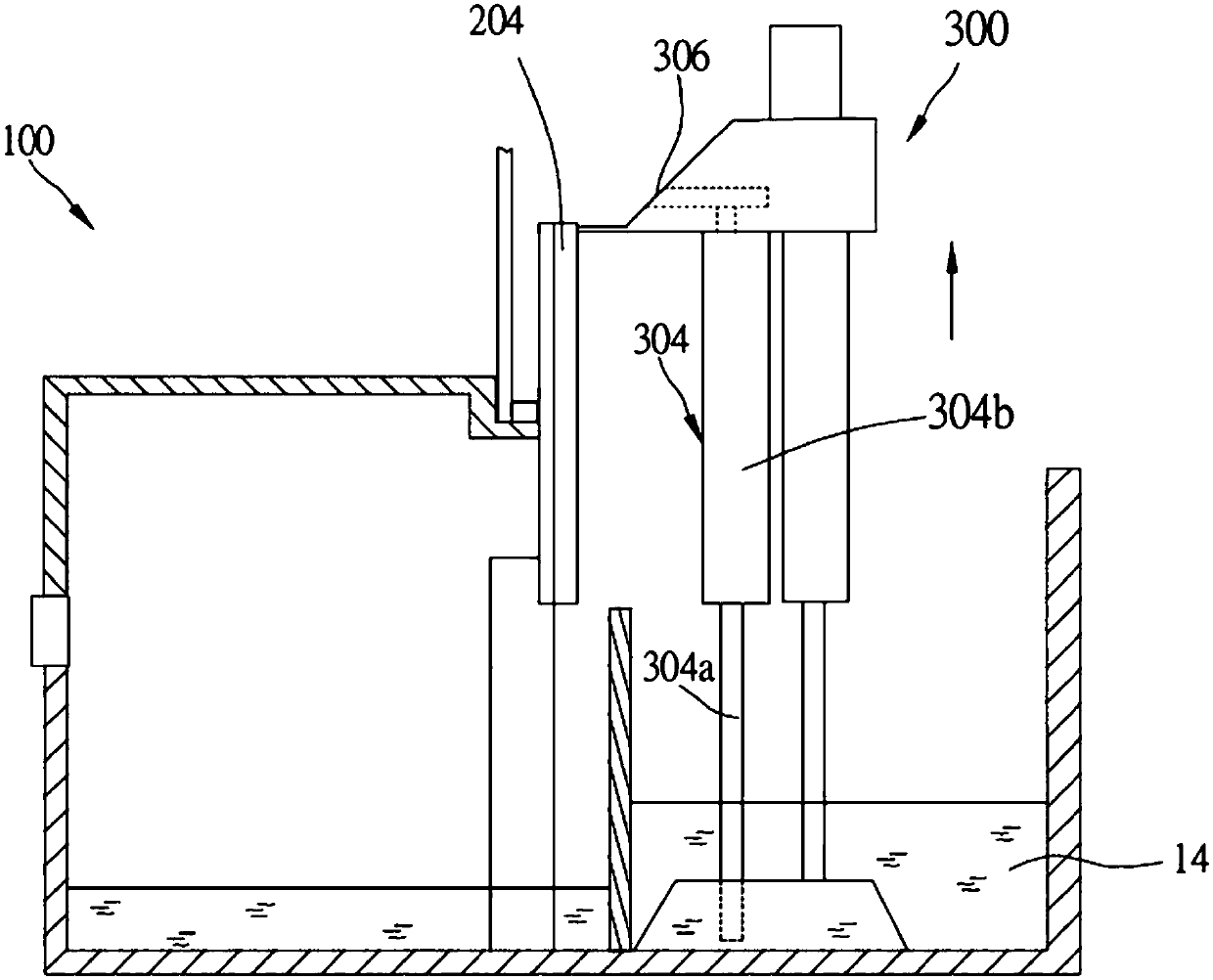

[0026] In order to illustrate the present invention more clearly, the following preferred embodiments are given in detail with reference to the accompanying drawings. Please refer to Figure 1 to Figure 5 As shown, the mop cleaning bucket 100 that can isolate dirty water and clean water according to a preferred embodiment of the present invention is used to clean a flat mop 200, and the flat mop 200 is wet-cleaned through a cleaning structure 300, wherein The mop cleaning bucket 100 includes a bucket body 10, an upper cover 20 and a support member 30, wherein the inside of the bucket body 10 is connected to the bucket body 10 through a partition plate 12 to separate a clean water tank 14 that does not communicate with each other. and a drain tank 16; and the flat mop 200 includes a handle 202 and a flat brush 204, wherein the handle 202 is held by the user's hand, and one end of the handle 202 is pivotally connected to the flat brush 204; And this cleaning device 300 comprise...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap