chimney dust filter

A technology of dust filtration and chimney, which is applied in the direction of dispersed particle filtration, separation method, dispersion particle separation, etc. It can solve the problems of affecting the filtering effect, easy accumulation of dust, unfavorable dust cleaning, etc., so as to avoid blocking the passage of exhaust gas and achieve high filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

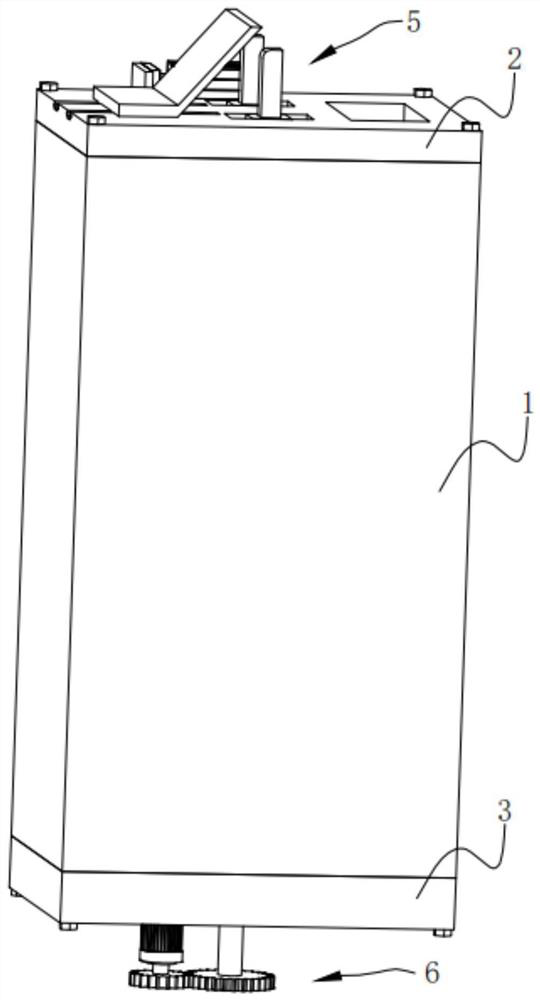

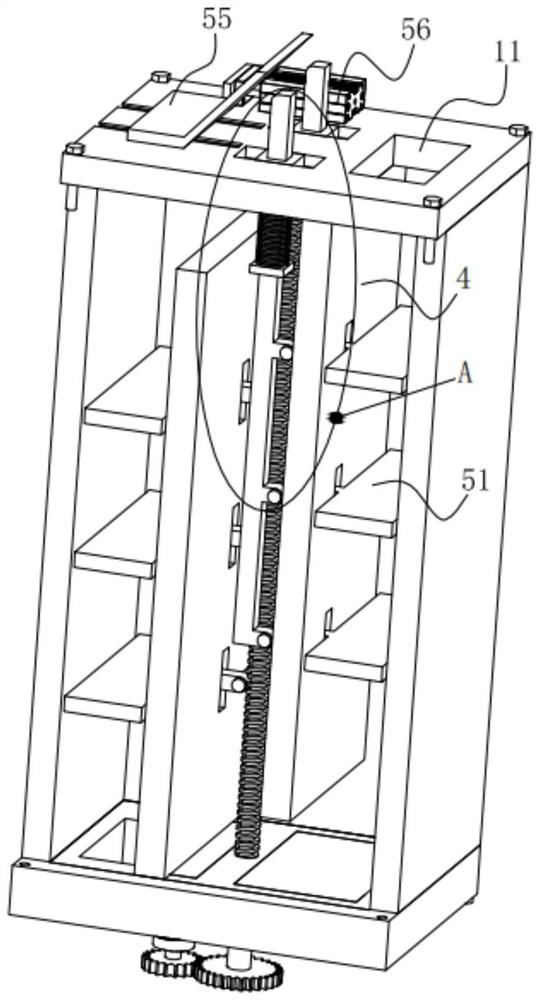

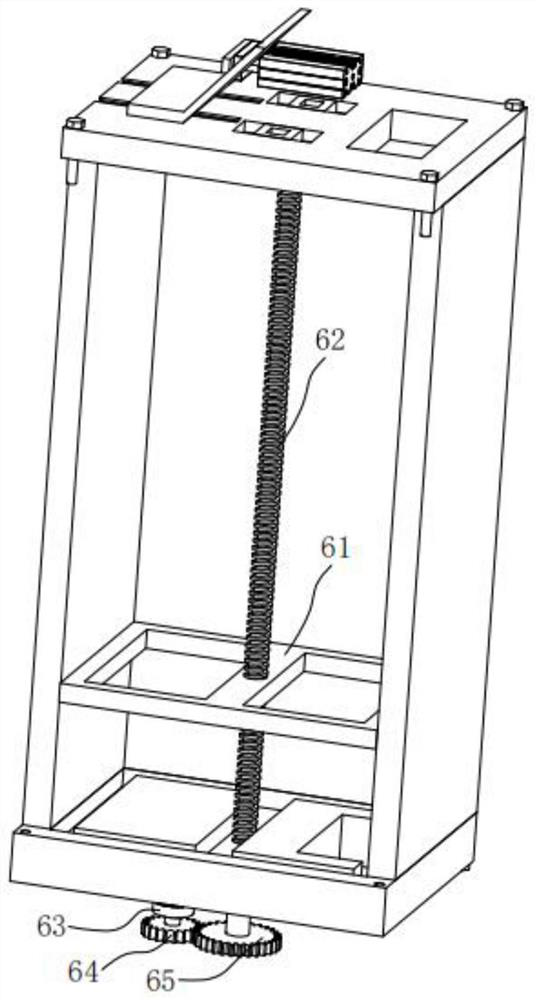

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0024] A chimney dust filtering device, comprising a chimney 1, an upper cover plate 2, a lower cover plate 3, a baffle plate 4, a filter mechanism 5 and an ash removal mechanism 6, wherein:

[0025] The upper end of the chimney 1 is provided with an upper cover plate 2, and the lower end is provided with a lower cover plate 3, wherein the upper cover plate 2 and the lower cover plate 3 are respectively installed on the upper and lower ends of the chimney 1 by bolts, and the upper cover plate 2 and the lower cover plate 3 and the chimney 1 are provided with a sealing ring, wherein the lower cover plate 3 is provided with a mounting groove 31, and the two baffles 4 are respectively installed inside the chimney 1 by bolts and divide the inside of the chimney 1 into three chambers, Both the upper cover plate 2 and the lower cover plate 3 are provided with ventilation holes 11, the ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com