A multi-stage stone crushing device

A crushing device and stone technology, applied in separation methods, cleaning methods and utensils, dispersed particle separation, etc., can solve the problems of high electric energy, inconvenient use, reduced crushing efficiency, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

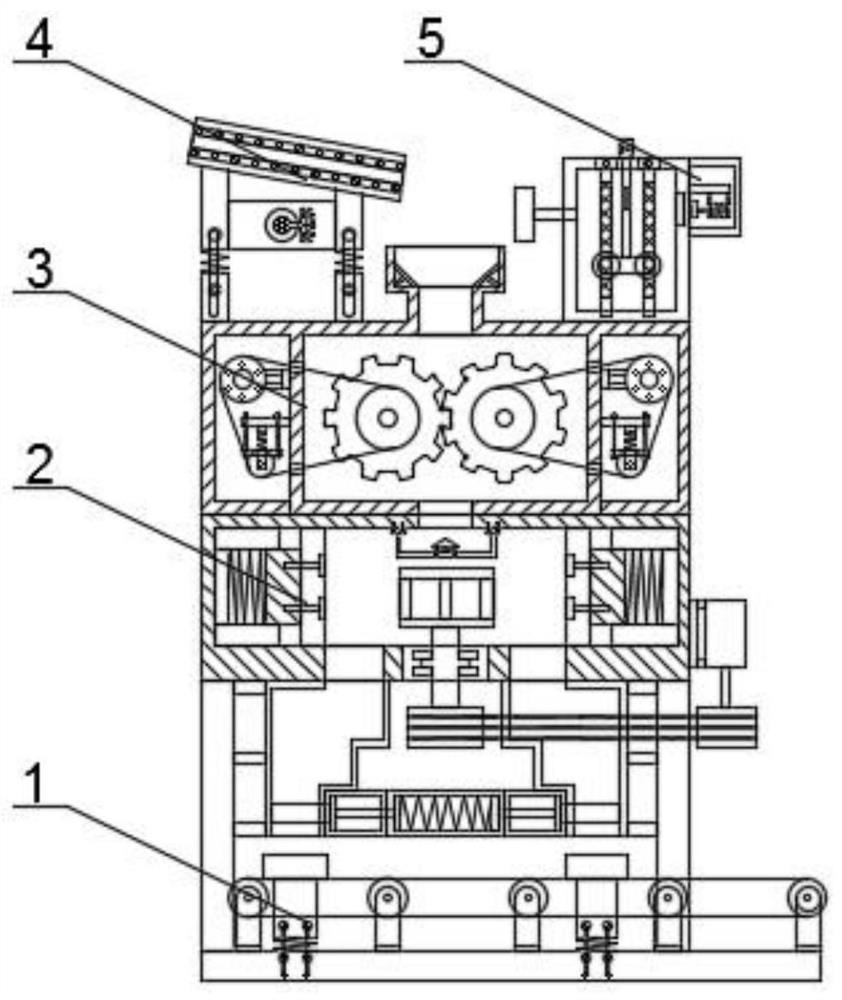

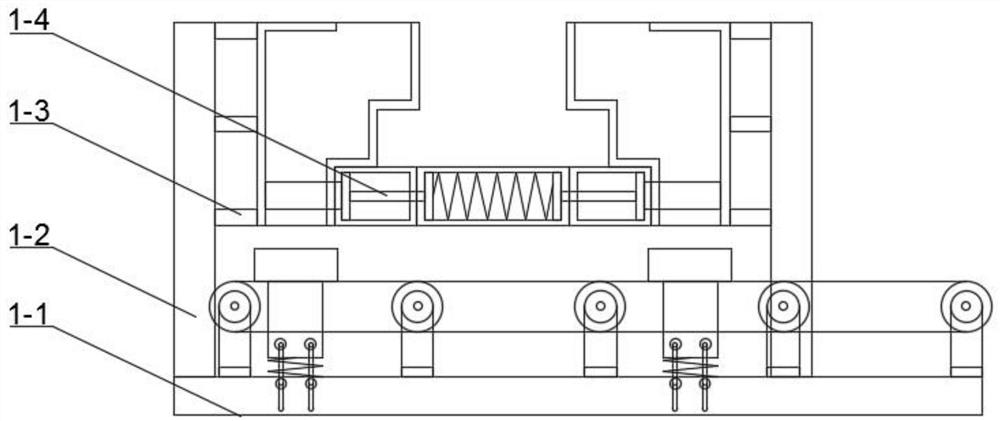

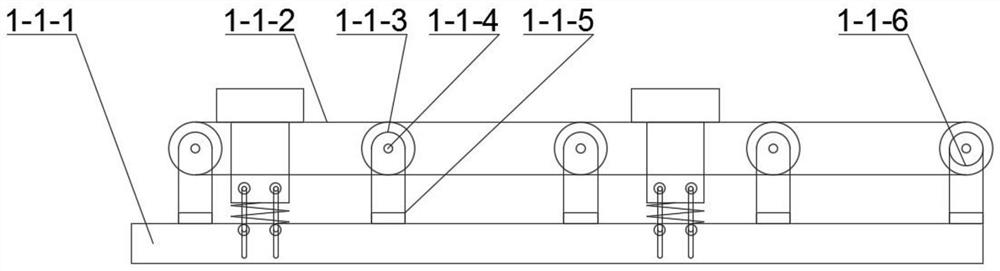

[0048] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 To illustrate this embodiment, the present invention relates to a crushing device, more specifically a multi-stage stone crushing device, including an automatic unloading and feeding mechanism 1, a stone shaping mechanism 2, a stone crushing mechanism 3, an automatic feeding mechanism 4, Dust removal mechanism 5, the device can feed materials automatically, the device can crush the stone, the device can tension the belt, the device can shape the stone, the device can automatically unload the material, the device can prevent the belt from being damaged, and the device can crush the broken stone After transportation, the device can guarantee a long service life, and the device can remove dust.

[0049] The automatic unloadin...

specific Embodiment approach 2

[0067] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 This embodiment will be described. This embodiment will further describe the first embodiment, and the number of the above-mentioned dropping hoppers 1-3 is two.

specific Embodiment approach 3

[0068] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 Describe this embodiment, this embodiment will further explain Embodiment 1, the described drop hopper body 1-3-2, impact plate body 2-1-4, distribution tray 2-2-4, throwing tray 2- 3-1. The material of wear plate A4-3-2 is high manganese steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com