Automobile glass detection system and detection method

A technology of automobile glass and detection system, which is applied in sorting and other directions, and can solve problems such as insufficient detection methods of automobile glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

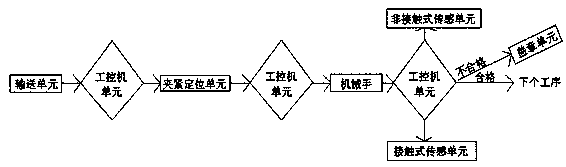

[0034] Embodiment 1: The conveying unit transports the automobile glass to be detected to the designated place, and sends a clamping glass instruction to the industrial computer unit;

[0035] The clamping and positioning unit is set on the workbench, accepts the clamping glass instruction issued by the industrial computer unit, and sends the clamping and positioning completion command to the industrial computer unit, receives the glass on the conveying unit, and performs clamping and positioning on the glass;

[0036] A set of touch sensor units, each touch sensor unit is set on the positioning tool through a pneumatic slide table, used to move around the edge of the glass, detect the data value of the edge of the glass by contact, detect the shape and size of the glass, and store the data of the edge of the glass The value is sent to the industrial industrial computer unit;

[0037] The non-contact sensor unit is set on the working end of the manipulator and above the glass ...

Embodiment 2

[0057] Embodiment 2: The glass is transmitted to the clamping and positioning unit through the transmission line, and the transmission line issues a clamping glass command. After the glass is clamped, a detection command is sent to the manipulator. The manipulator drives a high-precision laser sensor to scan the glass detection point, and at the same time detects the glass. The shape and size touch probes are extended and begin to inspect the glass shape and size. The detection data of the contact size probe is synchronously transmitted to the PC through the data collector. The industrial computer unit reads the real-time value of the laser sensor through the bus. At the same time, each time the laser sensor sends the measured value, it will use its own crystal oscillator to send a synchronous pulse output signal. The pulse signal is directly sent to the KUKA manipulator, and the manipulator receives the pulse. After the signal, send the current real-time position of the manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com