On-line calibration system and method for external parameter of monocular camera

A calibration method and calibration system technology, applied in the field of monocular camera external parameter online calibration system, can solve the problems of difficult processing and maintenance of high-precision three-dimensional calibration objects, poor robustness, etc., to achieve reduced impact, simple implementation, and strong flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

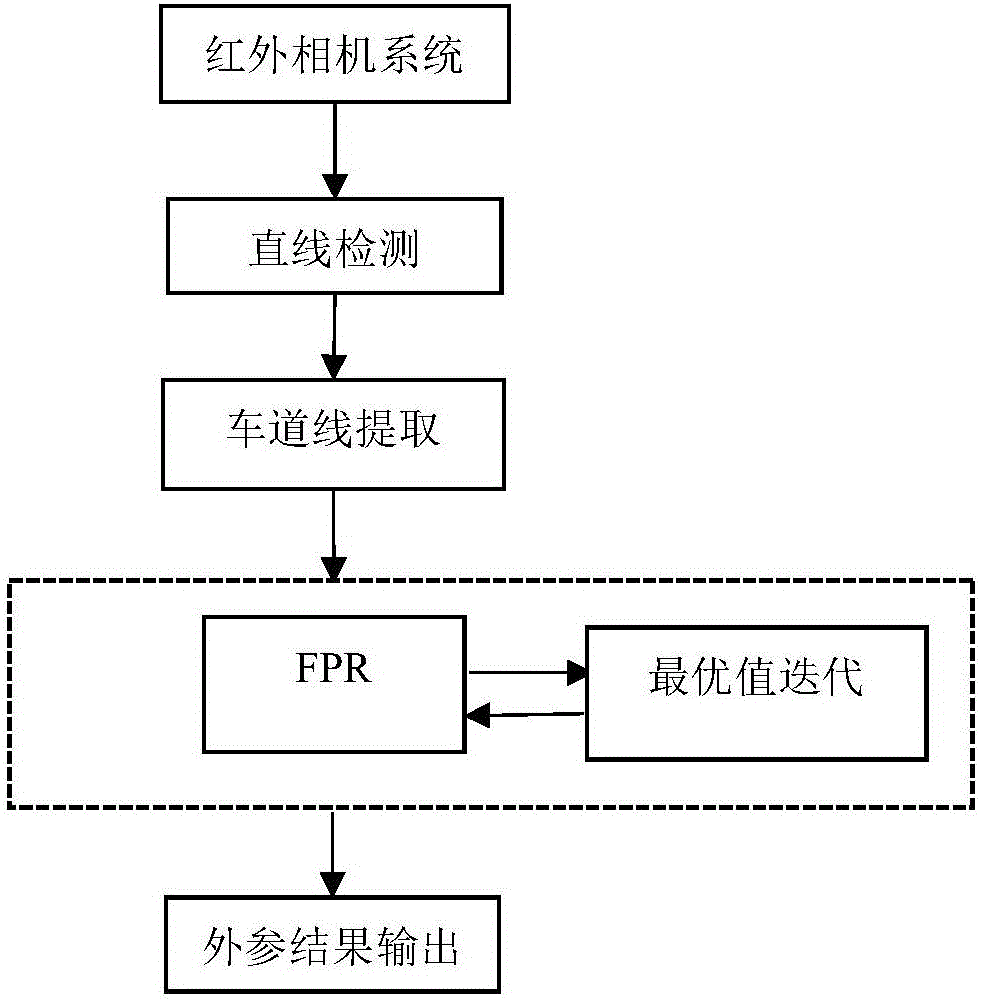

[0059] Aiming at the application of infrared cameras in assisted driving of vehicles, the present invention provides a system and method capable of automatic calibration of camera extrinsic parameters, which can obtain the roll angle, pitch angle and yaw angle of the camera installation in real time, which can be used for possible follow-up Modules such as identification provide data protection.

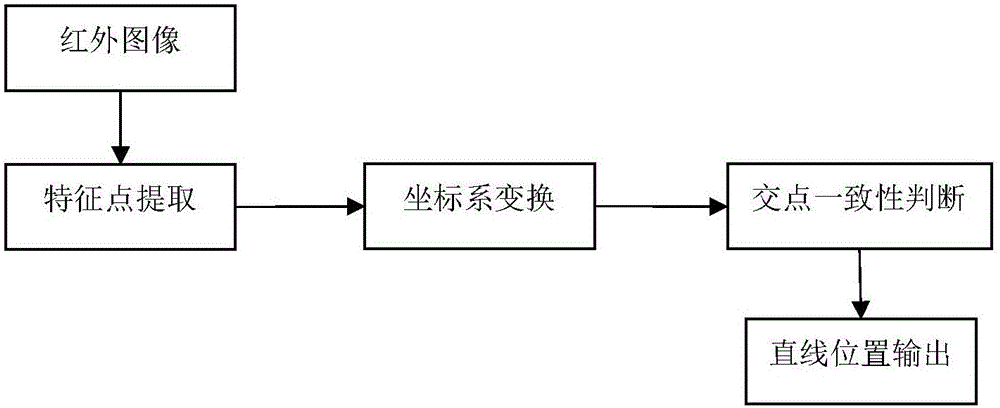

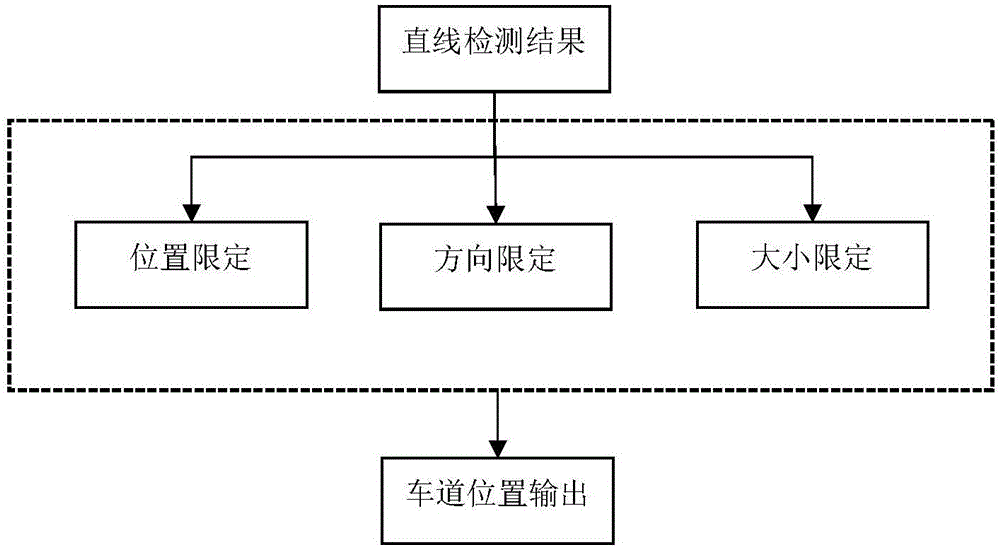

[0060] The present invention uses the real-time image of the infrared camera as the main input, supplemented by the internal reference information of the camera. The infrared image is input at a frame rate of 30 frames, and the self-calibration method is used to perform online calibration of the camera's external parameters a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com