Hoisting system used for overall transportation of Bailey bridge and construction method of hoisting system

A technology of integral transportation and Bailey bridge, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem that the overall stability of Bailey bridge is not easy to guarantee, repeated lifting work cannot be performed, and high safety cannot be guaranteed , high efficiency and other issues, to achieve the effect of overcoming the lack of stability, high utilization rate of safety and stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

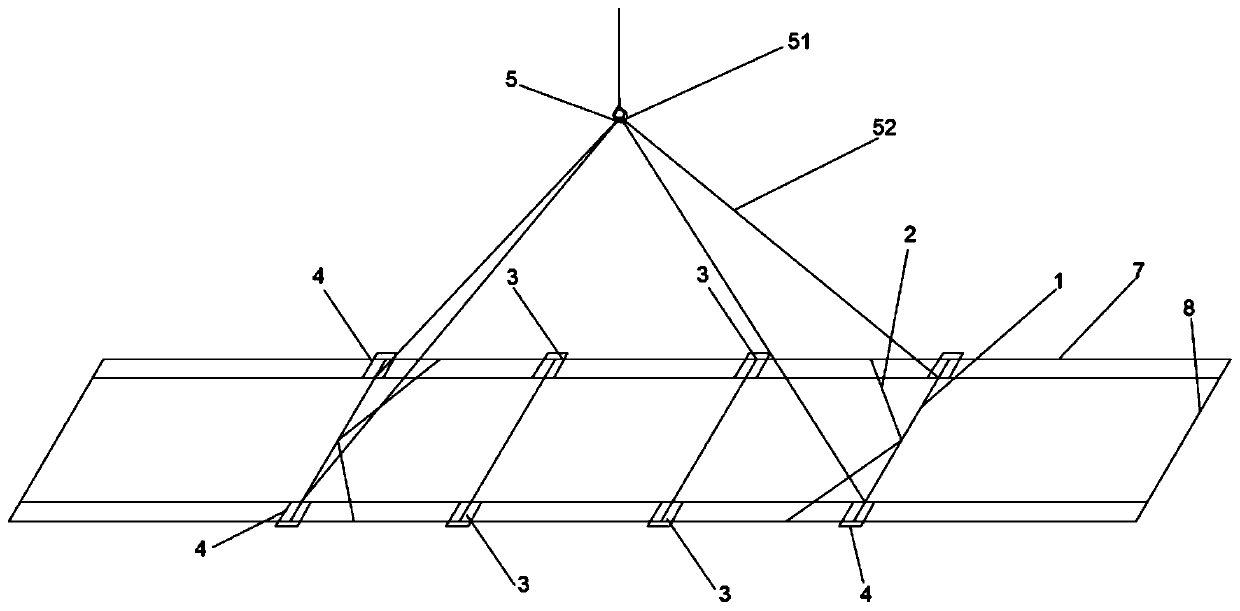

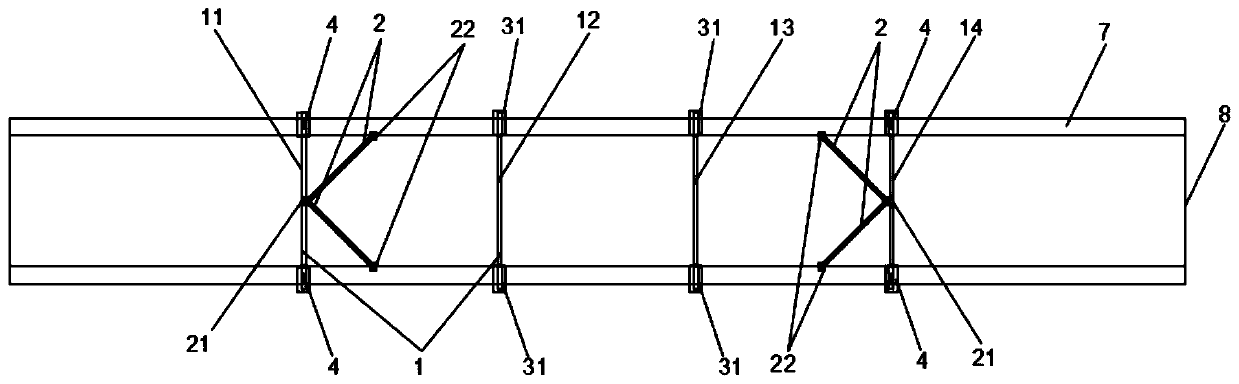

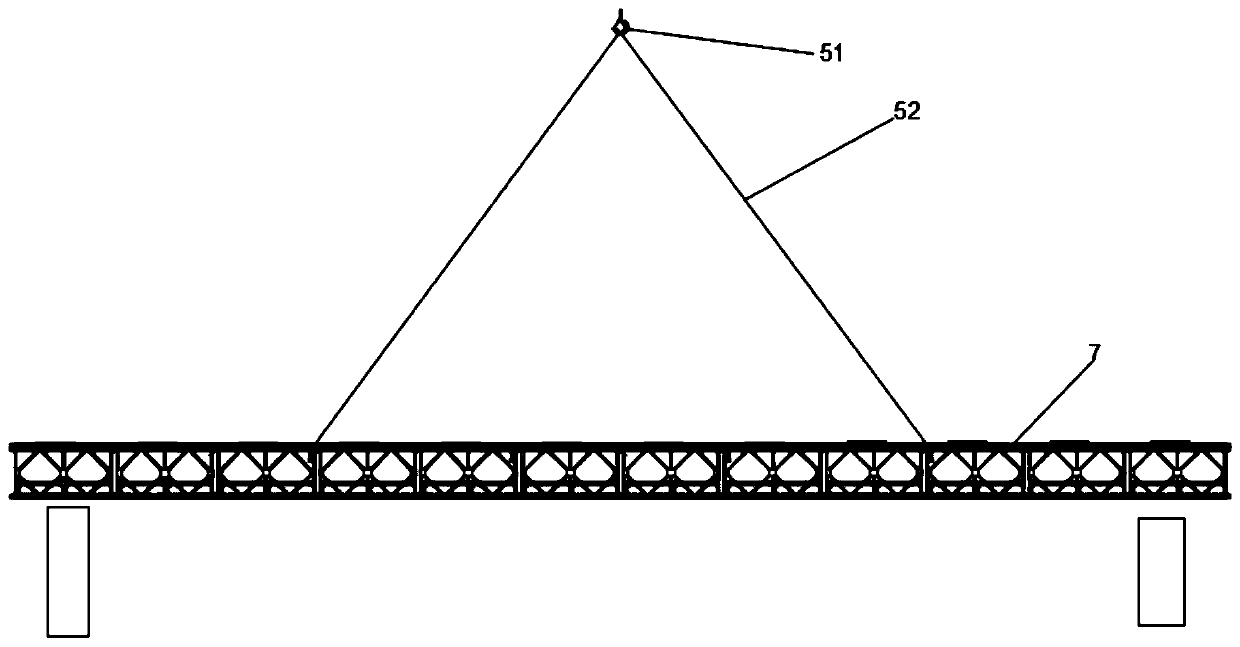

[0038] A hoisting system for the overall transportation of the Bailey Bridge. The Bailey Bridge is divided into a long-side truss 7 and a wide-side truss 8 according to its length and width. The hoisting system mainly includes a brace structure 1, a diagonal brace structure 2, and a reinforcement structure 3. Lifting member 4 and lifting device 5;

[0039]The braced structure 1 includes at least two braced steel parts, which are horizontally installed on the long side truss 7 of the Bailey Bridge and parallel to the wide side truss 8 of the Bailey Bridge; the braced steel parts are 25b The cross brace structure is 4300mm in length, and the unilateral wing plate 15 with a length of 150mm is cut off from the two terminal ends of the brace steel piece, and the other side wing plate is left, and the two ends are installed on the shell through the lifting member 4 or the fixing member 31. On the long side truss 7 of Leiqiao; said pair of brace steel parts is provided with four, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com