Imide covalent organic framework material and preparing method and application thereof

A covalent organic framework and imide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, carbon monoxide, etc., to achieve high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

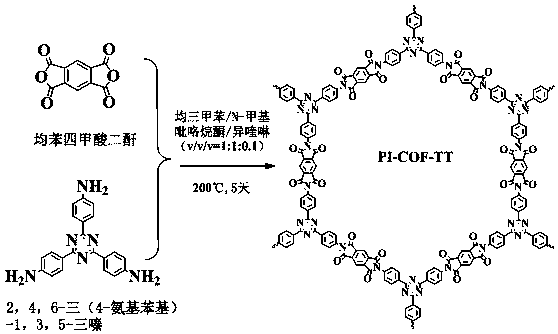

[0020] Put pyromellitic dianhydride (0.15 mmol) and 2,4,6-tris(4-aminophenyl)-1,3,5-triazine (0.10 mmol) in a Pyrex tube, add N-methyl Pyrrolidone / mesitylene / isoquinoline (volume ratio 1:1:0.1, total volume 1.05 mL), sonicate for 10 minutes. The Pyrex tubes were then snap frozen in a liquid nitrogen bath, evacuated to an internal pressure of 0 mbar and flame sealed. After warming to room temperature, the Pyrex tube was placed in an oven at 200 °C for 5 days. Soak in anhydrous THF for 8 h to activate, and then collect the precipitate by suction filtration with THF. The obtained powder was vacuum-dried at 80 ºC overnight to obtain PI-COF-TT.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap