Debugging bracket and method for infrared laser emitting head

A technology of infrared laser and debugging method, which is applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of human injury, inconvenient operation of infrared laser emitting head, and increase the scrapping rate of infrared laser emitting head, and achieve high debugging accuracy and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other if there is no conflict.

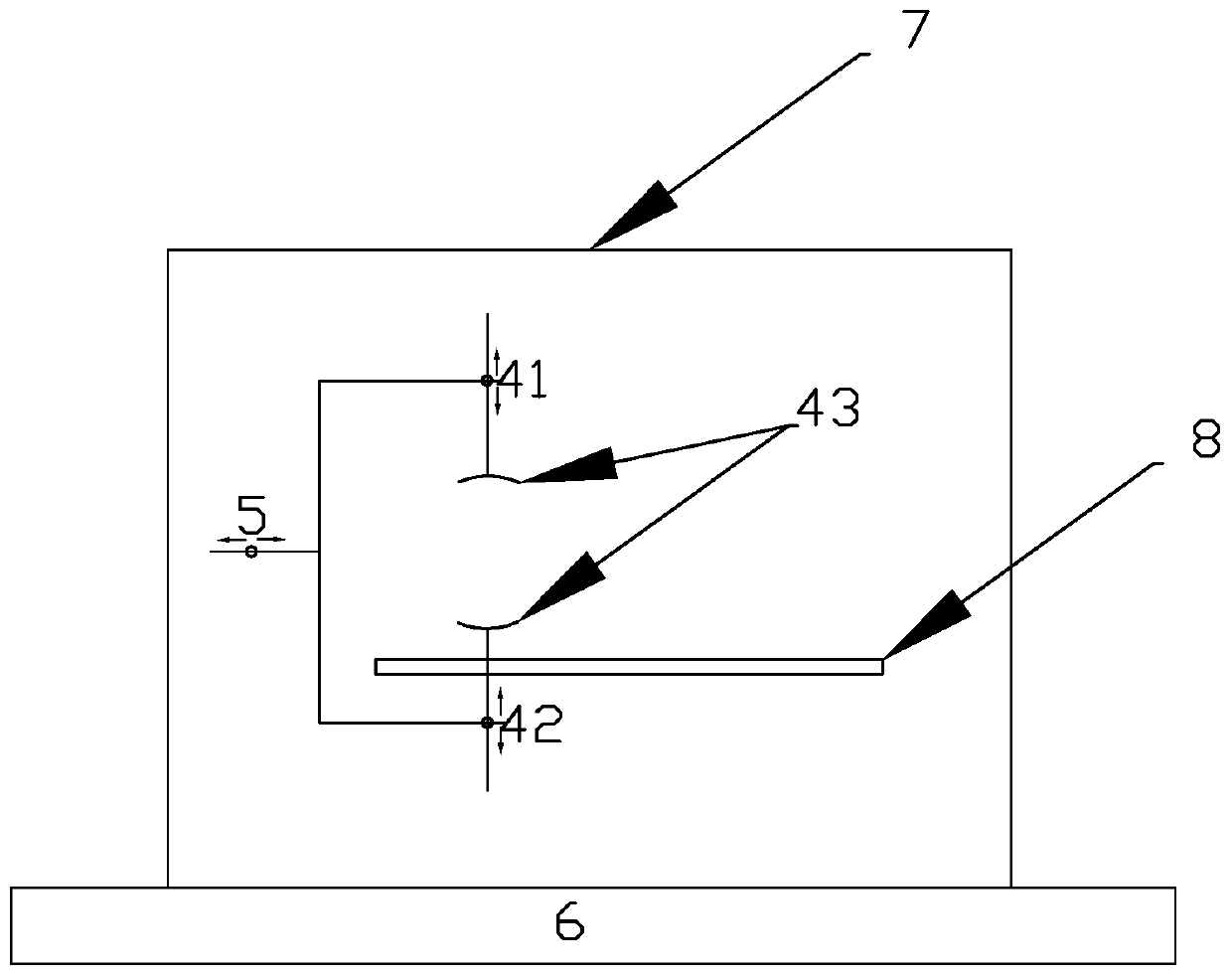

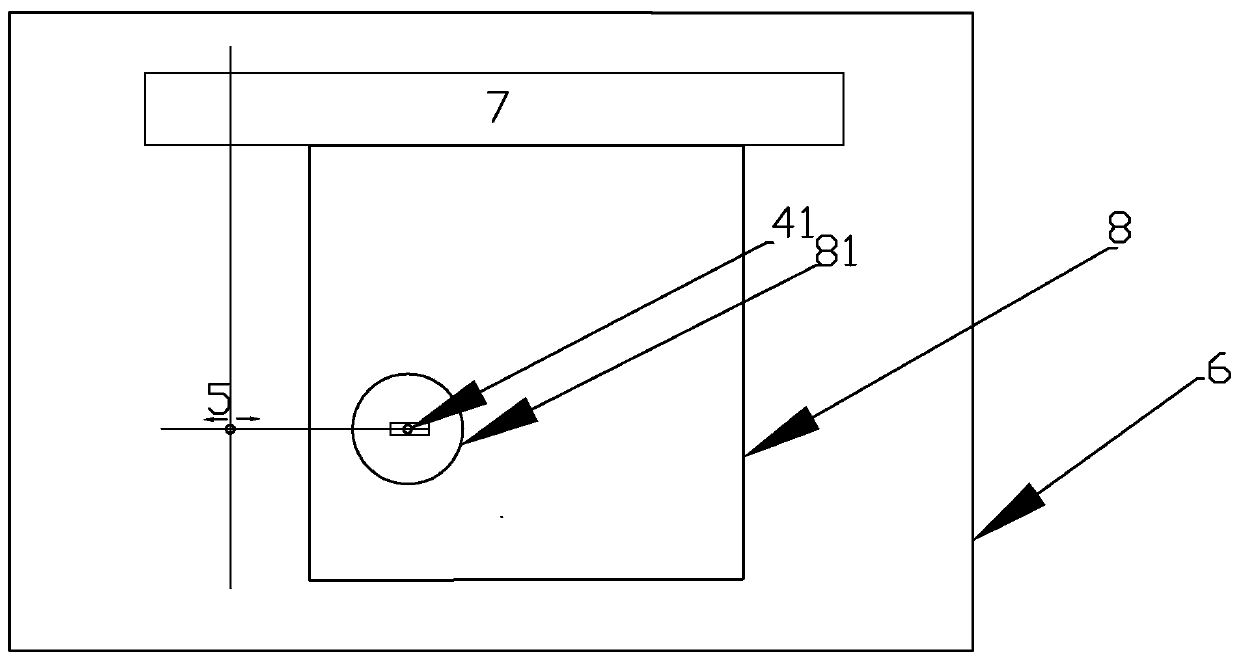

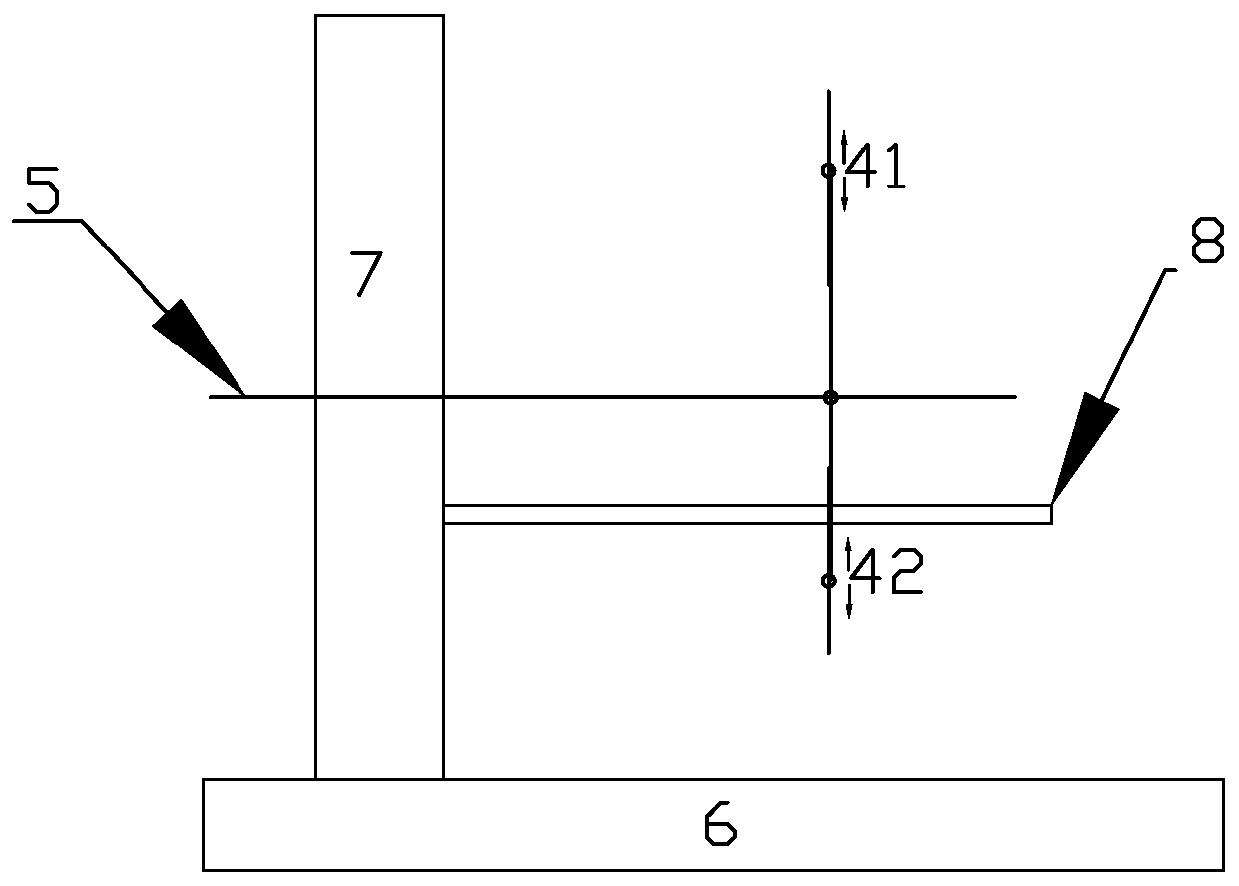

[0042] Such as figure 1 As shown, an infrared laser emitting head debugging support in the present invention includes: a base 6, a vertical support 7, a carrying support 8, a probe support 5, a first debugging probe 41 and a second debugging probe 42; , The vertical support 7 is vertically fixed above the base 6, the load support 8 is fixed on the vertical support 7, and the load support 8 is parallel to the base 6, the probe support 5 is fixed on the vertical support 7, the first debugging probe 41 Both and the second debugging probe 42 are fixed on the probe holder 5.

[0043] Specifically, refer to Figure 1 to Figure 3 , The end of the first debugging probe 41 and the end of the second debugging probe 41 are both provided with an arc-shaped clamping structure 43, the radii of the two arc-shaped clamping structures 43 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com