Equipment support leg

A technology of equipment and feet, applied in the field of supporting components, can solve the problems of non-adjustable height of the bracket, inconvenient use, uneven ground, etc., and achieve the effect of reducing workload, fast height, and height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

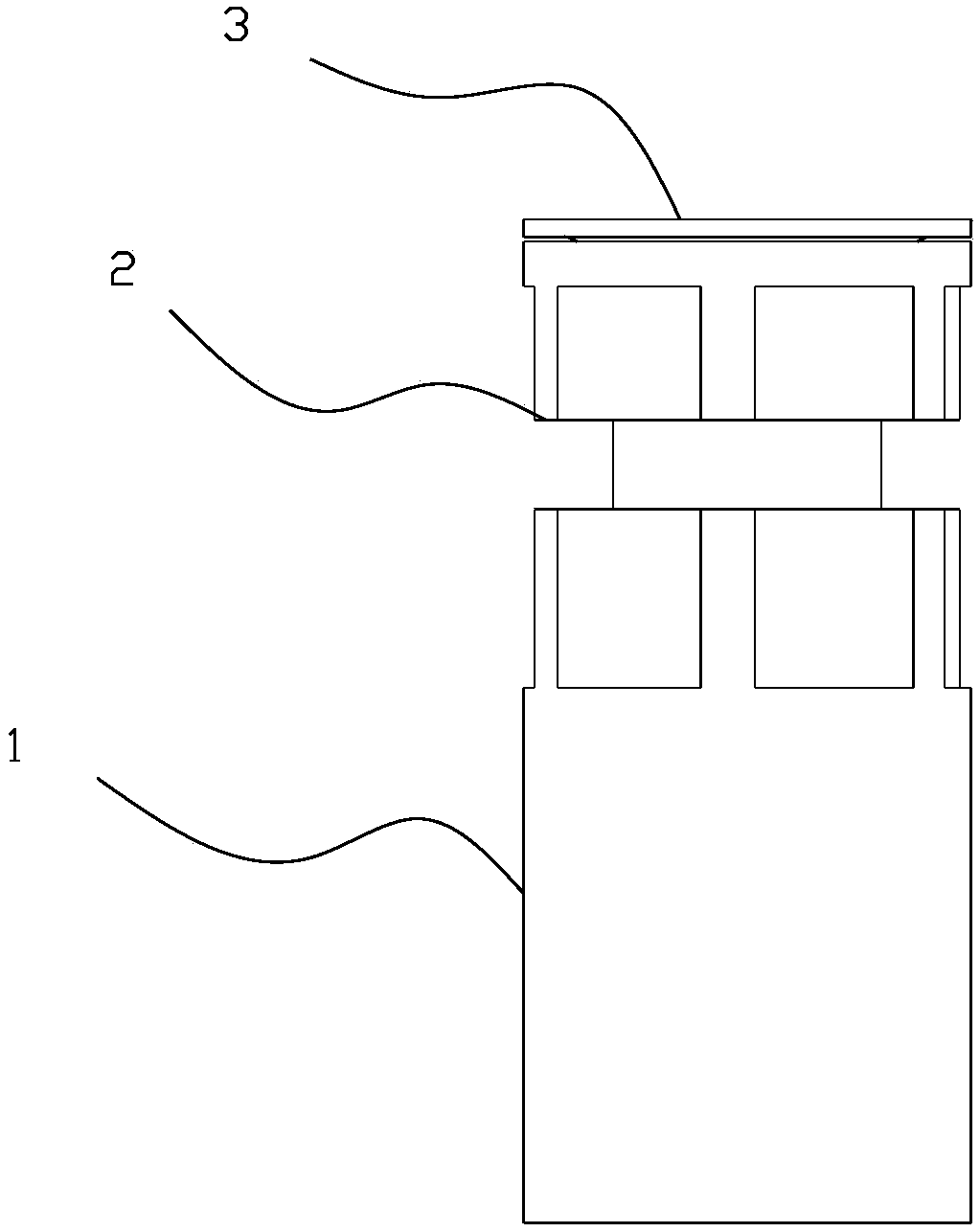

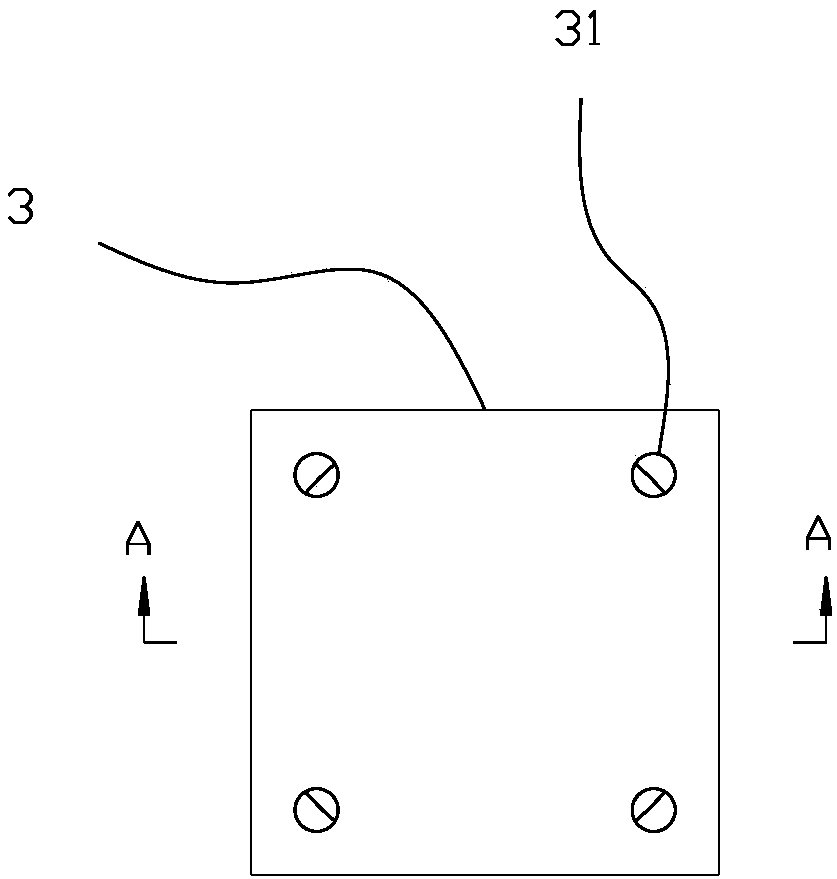

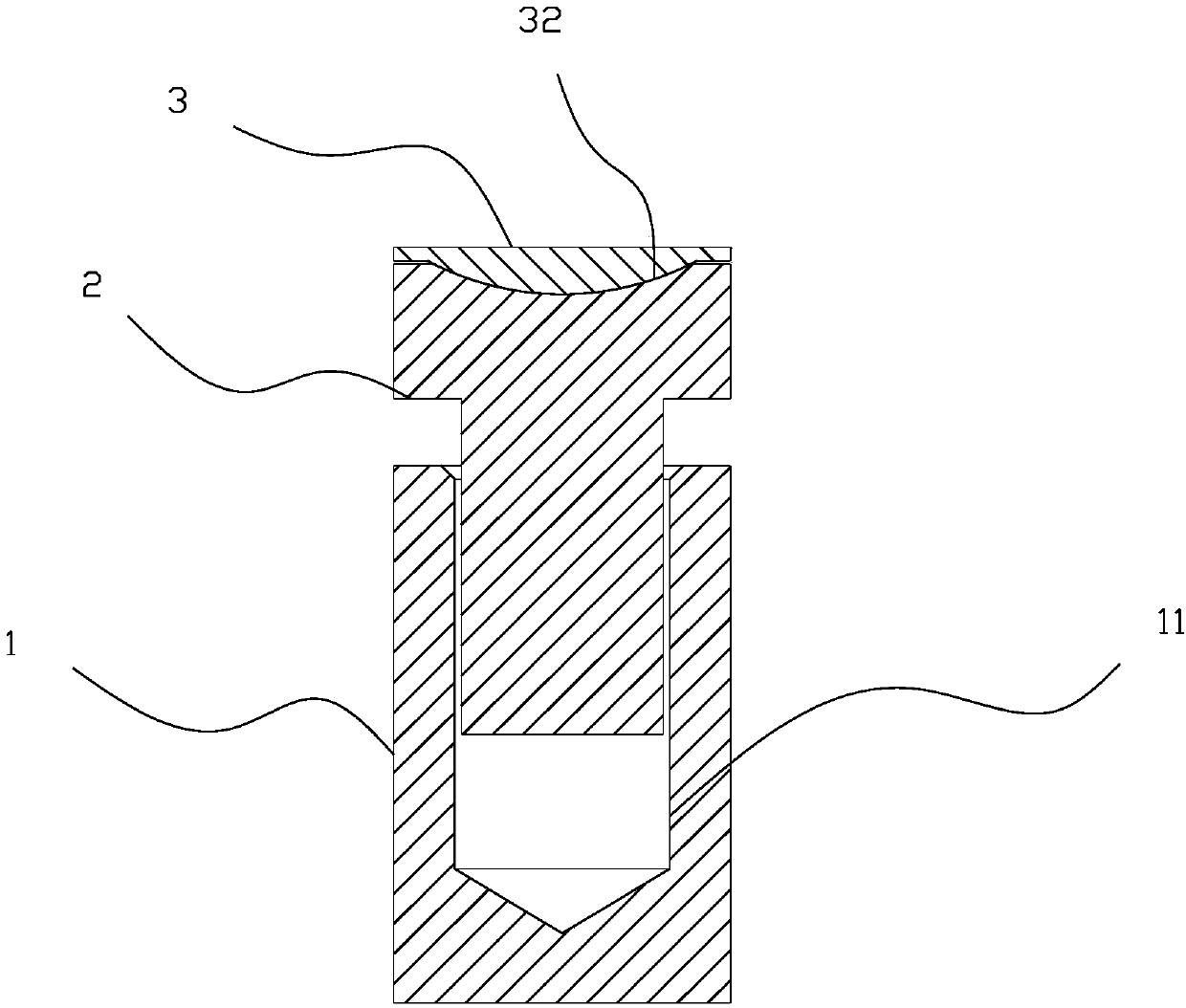

[0023] Figure 1-3 It is the first embodiment of the present invention, the bottom of the adjustment block 2 is a screw, the base 1 is provided with a screw groove 11 for equipment with the screw, and the adjustment block 2 or the base 1 is provided with a wrench to adjust the force noodle. The adjustment of the height of the equipment can be realized by adjusting the adjustment block 2 or the base 1 with a wrench. Because the upper block 3 and the adjustment block are not fixed, no force will be applied to the upper block 3 during the height adjustment process, and there will be no movement. On the device, it saves time and effort to adjust. The arc-shaped protrusion can reduce the frictional force between the upper block 3 and the adjustment block 2, so that the adjustment action is more labor-saving. A spring or an air bag can be installed under the screw rod, which can compensate the force of the overweight equipment and prevent the screw thread from being crushed and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com