Bearing fault diagnosis method combining improved sparse filter and KELM

A fault diagnosis and filter technology, applied in the testing of machine/structural components, instruments, and mechanical components, etc., can solve the problem that the KELM classifier cannot obtain classification results, ignore the internal structure of the input data, and cannot learn a high degree of discrimination. characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

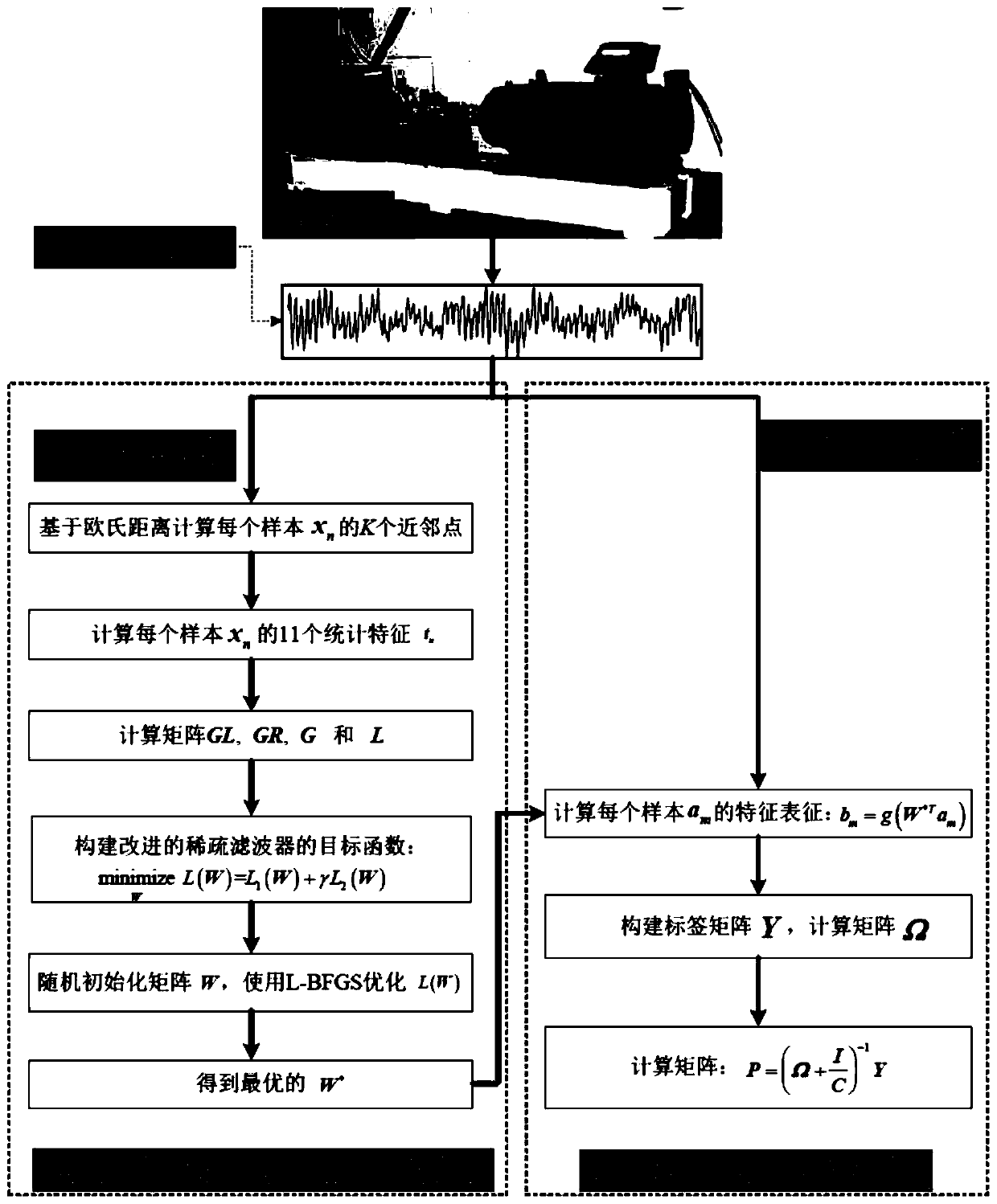

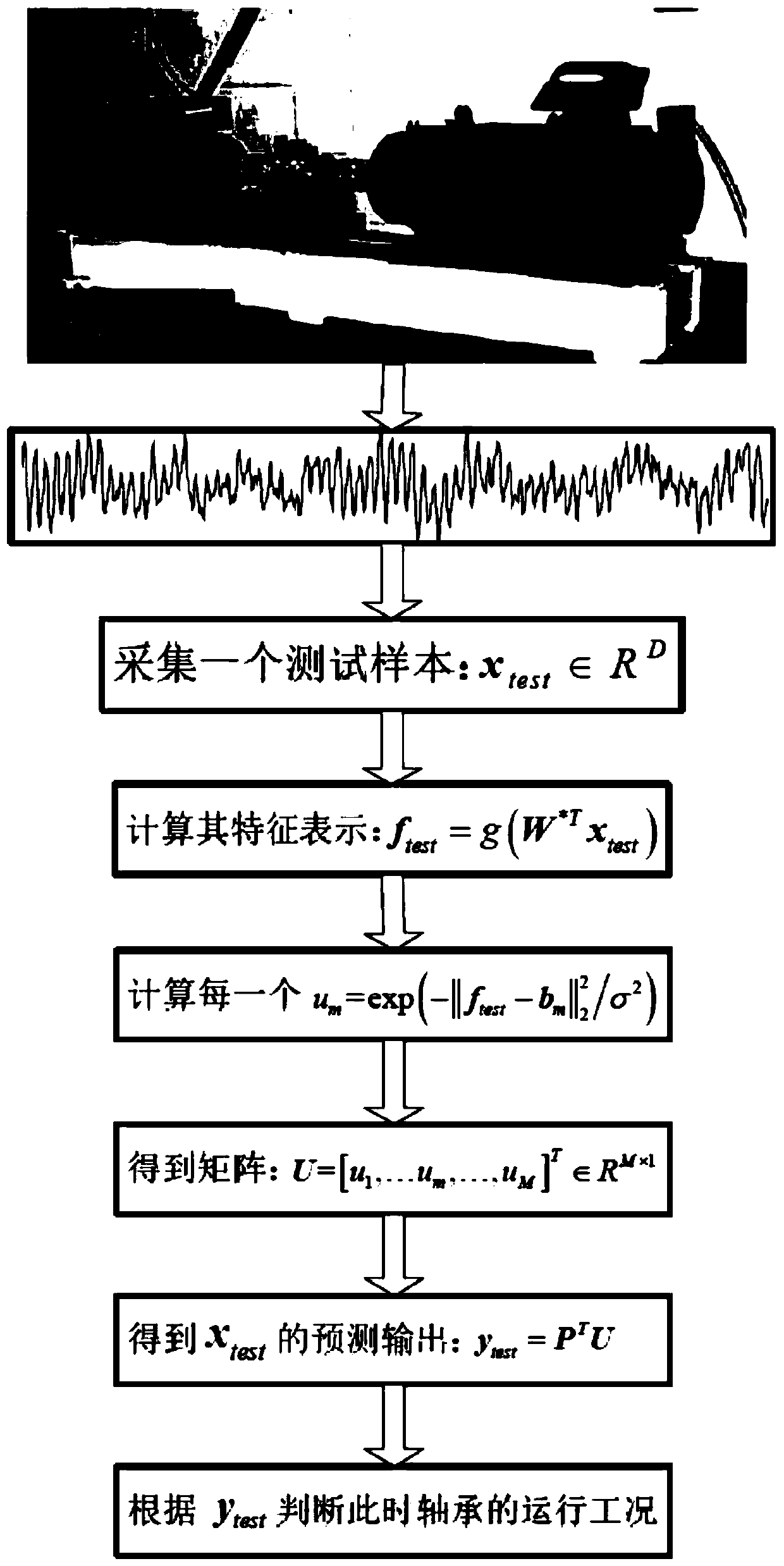

Method used

Image

Examples

Embodiment Construction

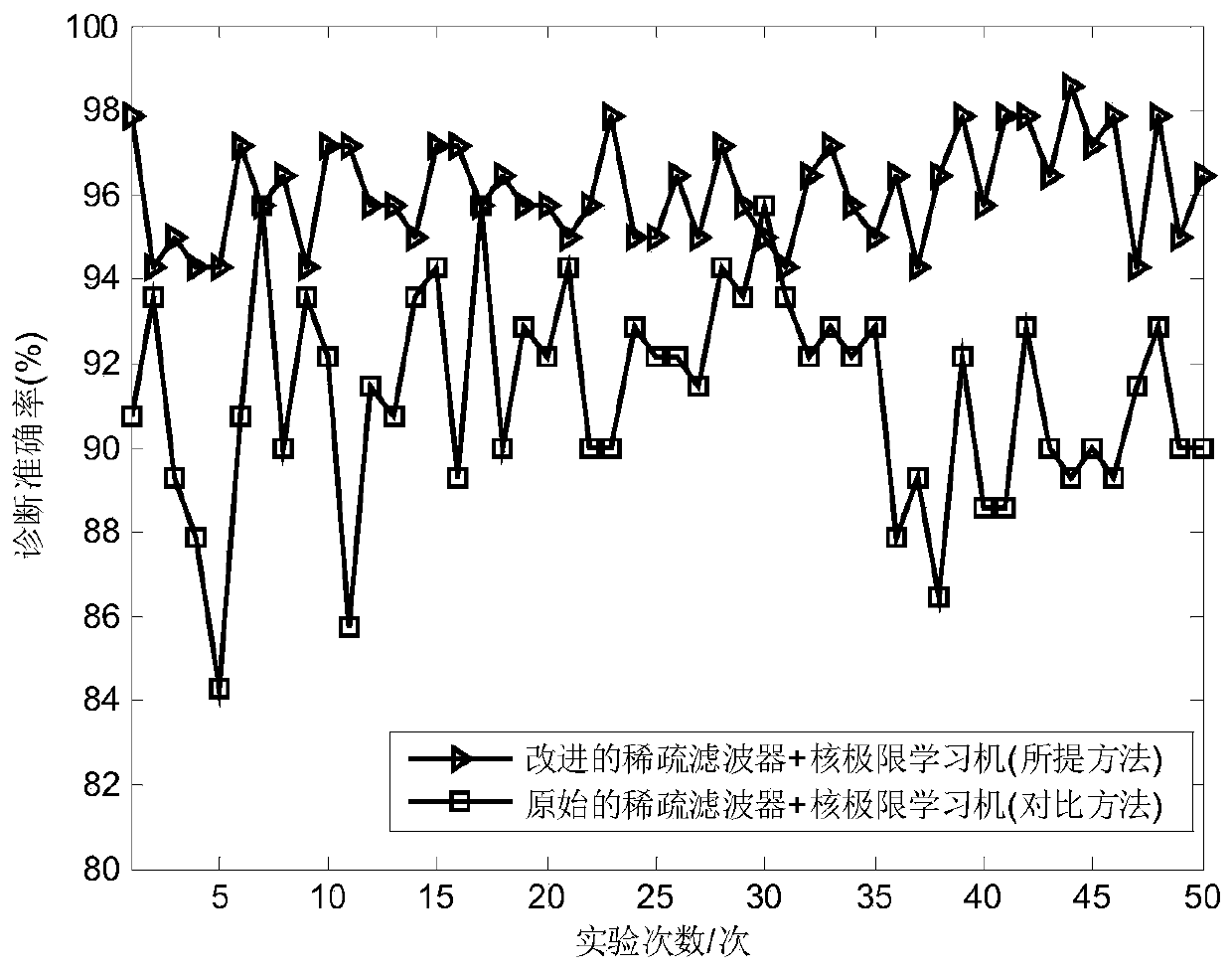

[0066] In order to verify the effectiveness of a bearing fault diagnosis method combining the improved sparse filter and KELM proposed by the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0067] A bearing fault diagnosis method combined with the improved sparse filter and KELM proposed by the present invention is verified using the standard data set provided by the Bearing Data Center of Western Reserve University. Collect the vibration signals of the three parts of the bearing under normal working conditions, inner ring, outer ring and rolling body at a speed of 1797rpm. These three parts have collected vibration signals of minor faults and serious faults respectively. In this way, seven types of vibration signals are collected in total. The working conditions are normal working condition, slight damage to the rolling body, serious damage to the rolling body, slight damage to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com