A heavy haul train operation curve multi-objective optimization method based on a hook buffer device model

A technology for heavy-duty trains and running curves, applied in genetic models, special data processing applications, instruments, etc., can solve problems such as not considering whether the coupler force exceeds the limit, no phase separation point research, etc., to maintain population diversity, Optimizing the running curve and the effect of energy-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with specific embodiments.

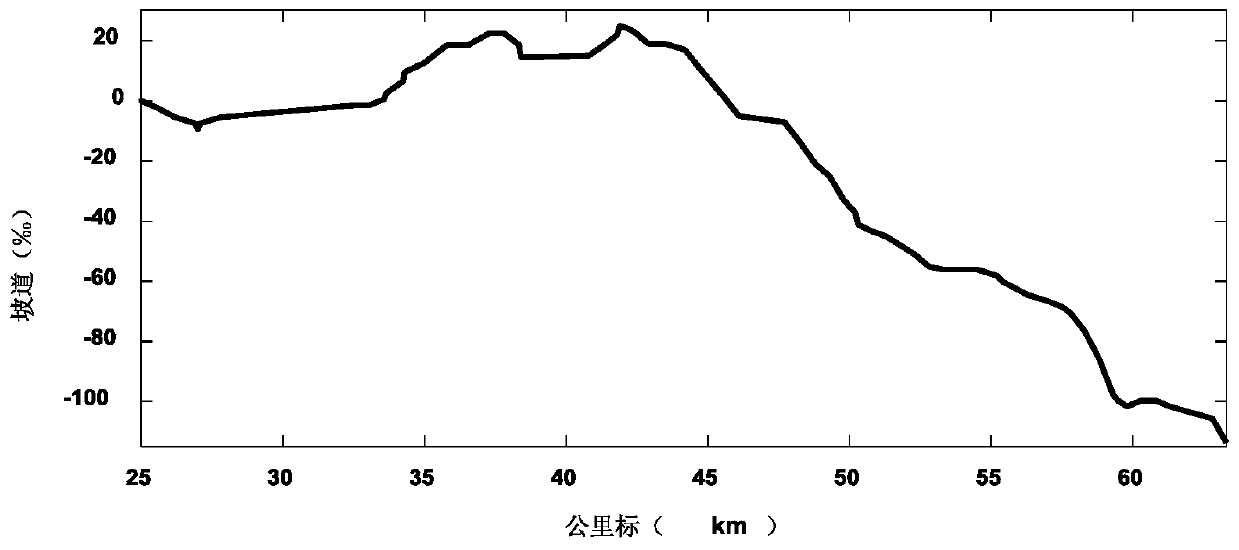

[0055] In the present invention, based on the multi-objective self-adaptive genetic algorithm, the optimization steps of the operation process of the heavy-duty train are as follows:

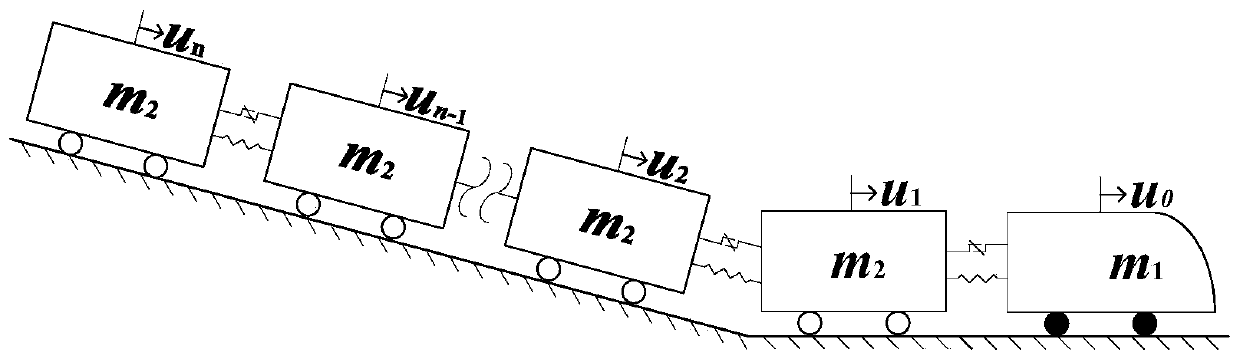

[0056] 1. Analyze the dynamic model during the operation of heavy-duty trains, such as figure 1 As shown, the longitudinal dynamic force of a single vehicle is analyzed, and the dynamic model of the motion process can be expressed as:

[0057]

[0058] In the formula, m i is the mass of the vehicle; is the acceleration of the vehicle; F T is the traction force, F D is the electric braking force; F CL is the front coupler force; F CR is the rear coupler force; F B is the air braking force; F W is the basic resistance of the vehicle running; F Wc is the curve resistance; F Wr is the ramp resistance.

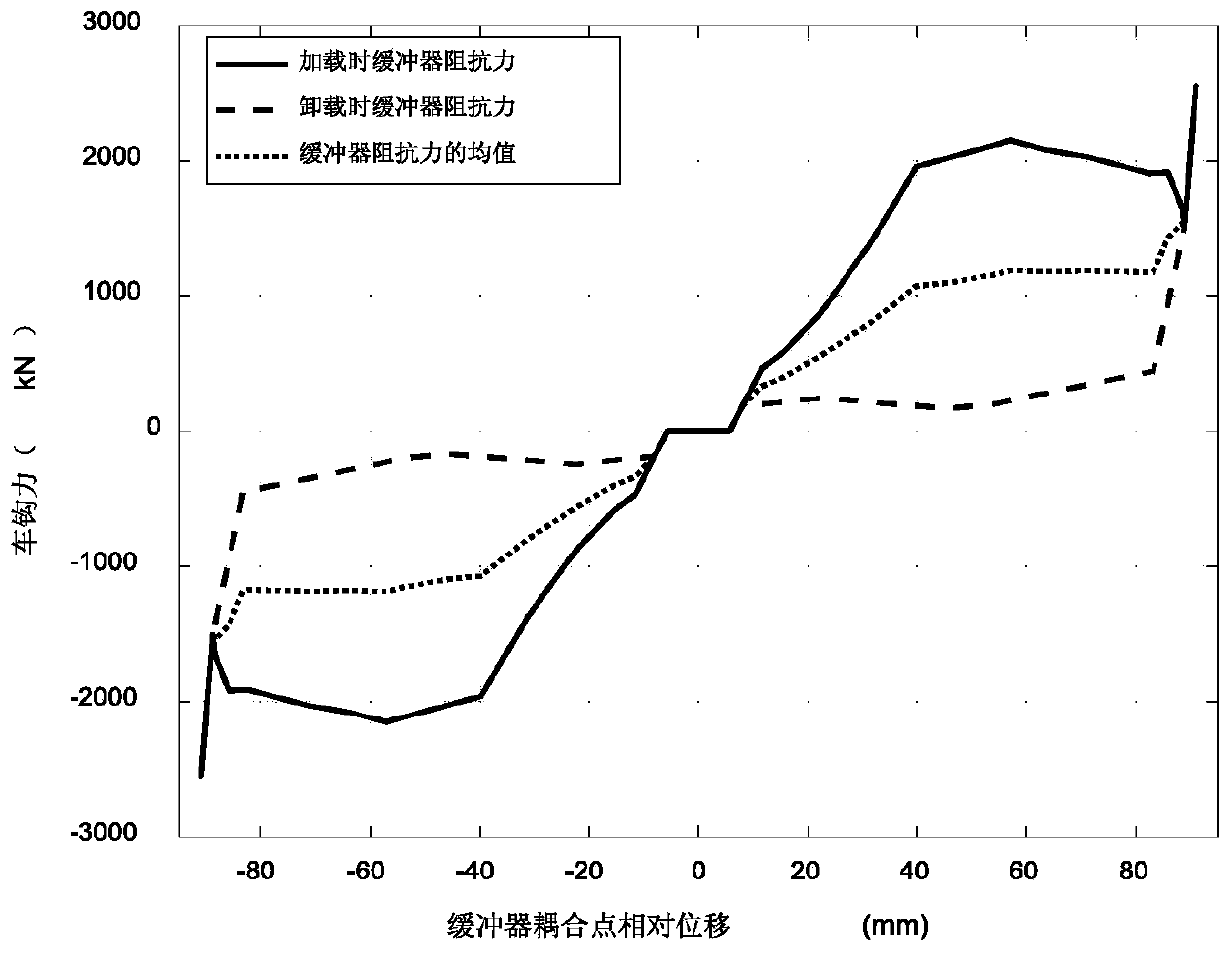

[0059] 2. Establish the model of the coupler buffer device. In the dynamic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com