Novel automatic heating vending machine for refrigerated box lunch

An automatic heating and vending machine technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items. It can solve the problem of long working hours of manipulators, complicated manipulator structures, and reduced sales efficiency. and other issues to achieve the effect of improving sales efficiency, facilitating equipment maintenance and repair, and reducing equipment failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

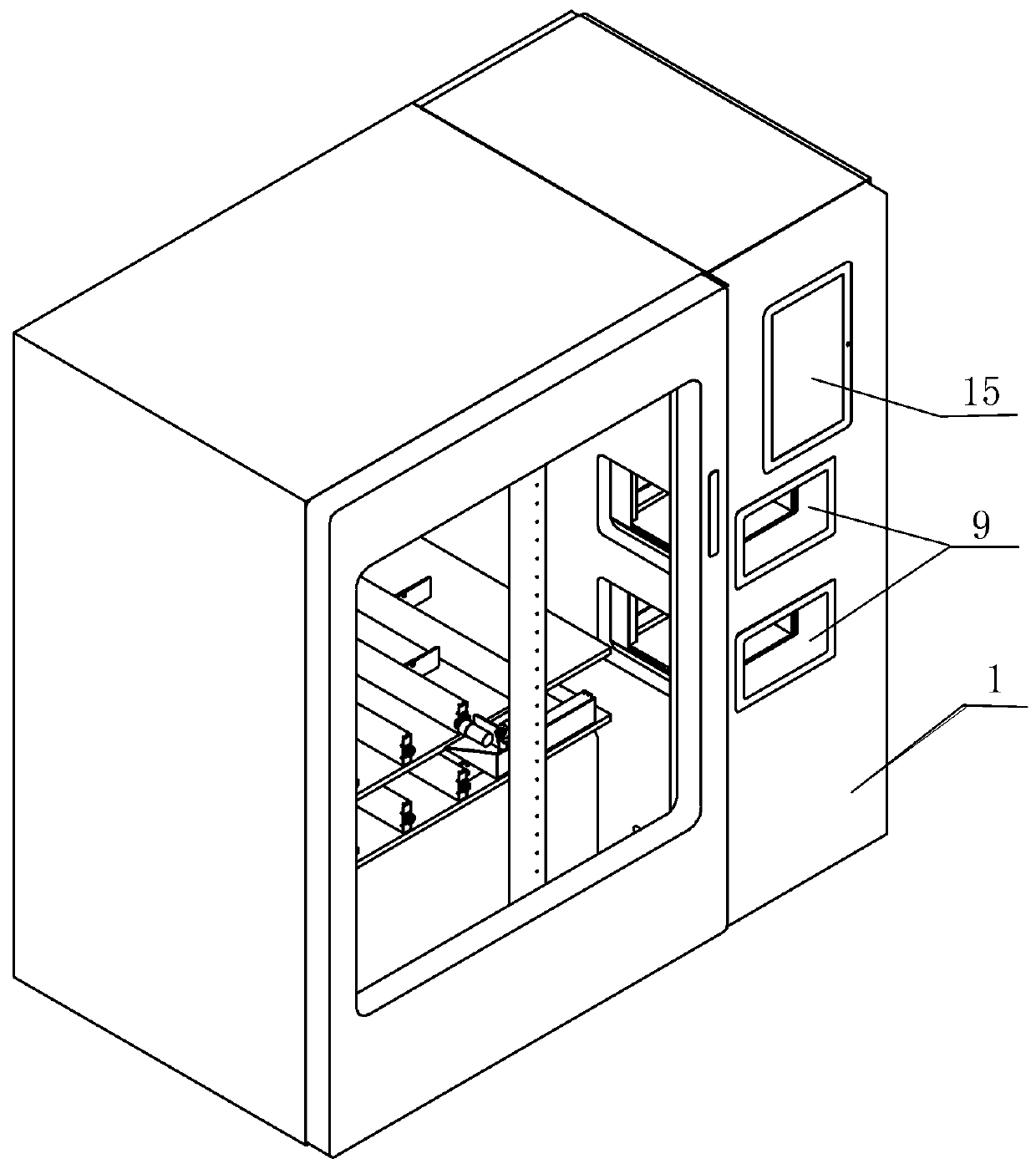

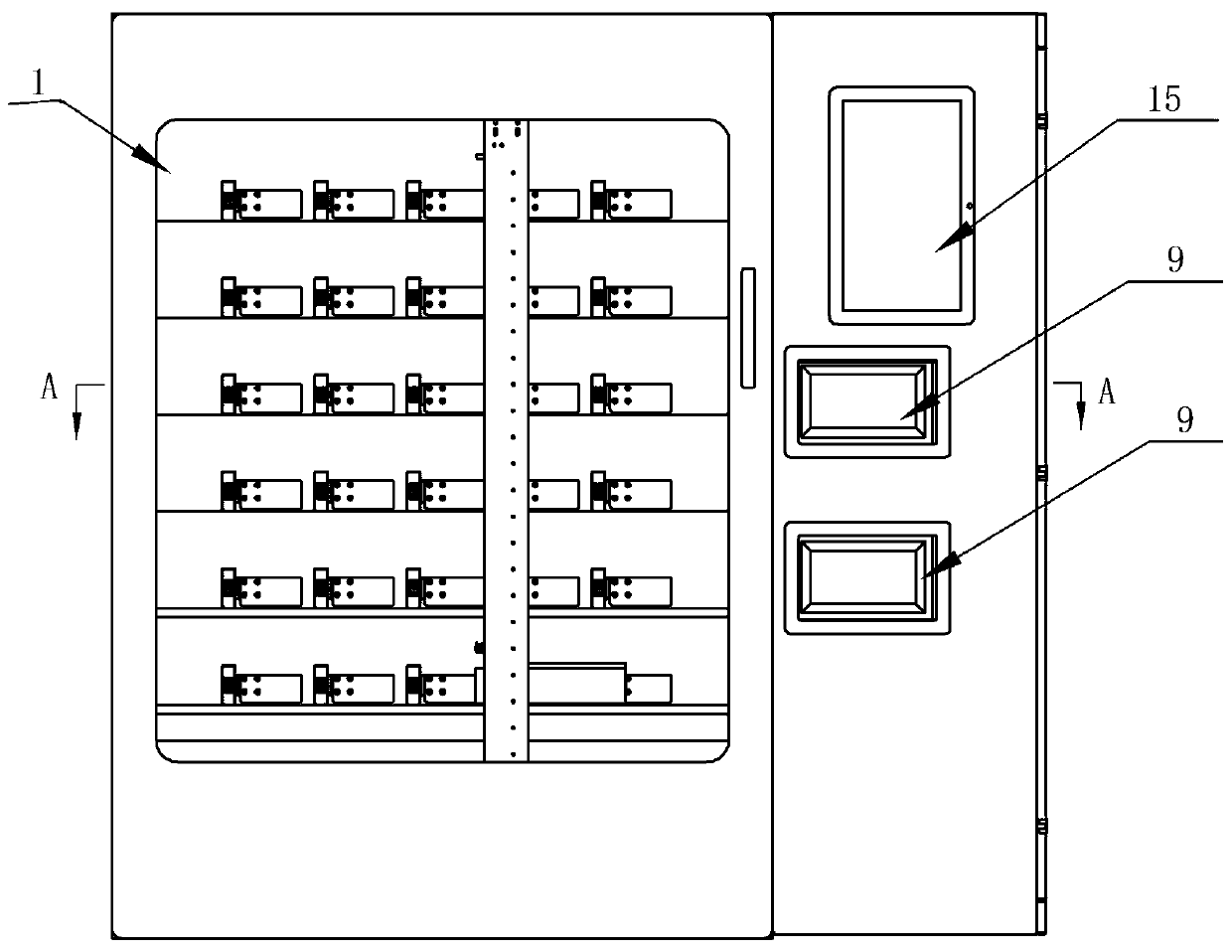

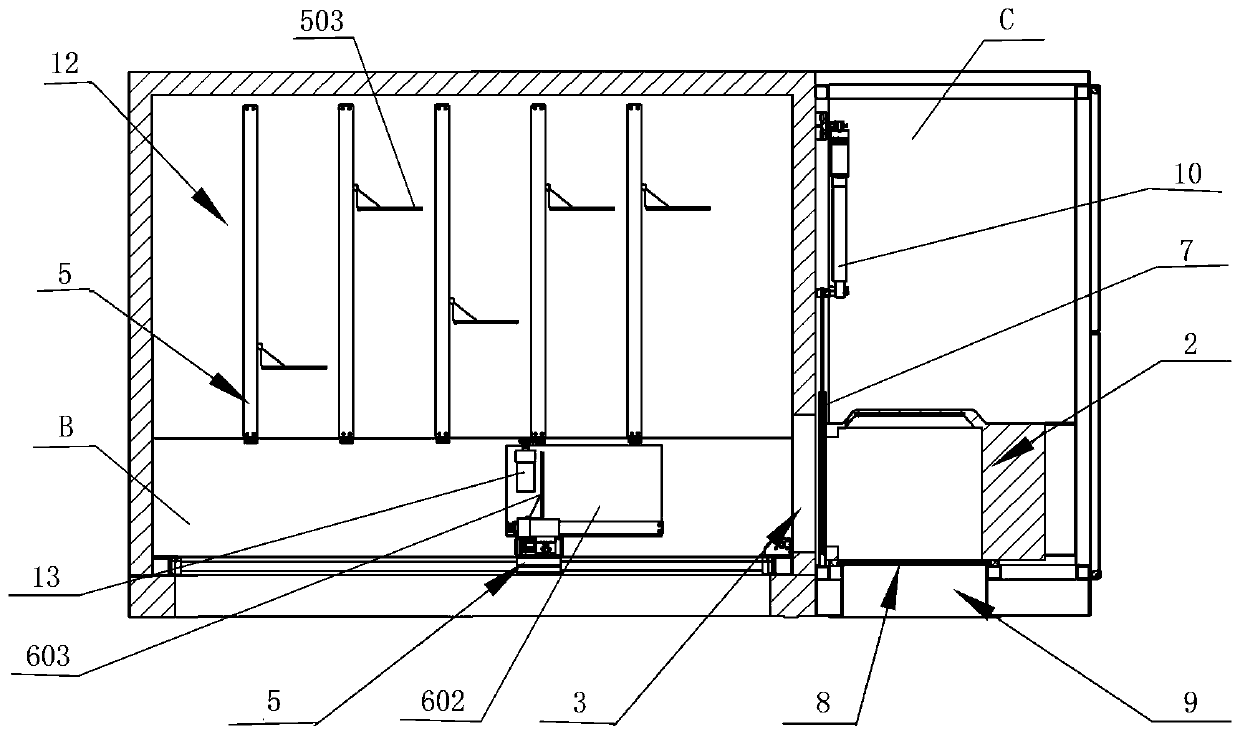

[0030] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 , in the figure, B-refrigerating zone, C-heating zone; a-X axis, b-Y axis, c-Z axis, d-X axis drive motor, e-Y axis drive motor;

[0031] 1-vending machine, 2-microwave oven, 3-feed inlet, 4-partition, 5-discharging mechanism, 6-feeding manipulator, 7-first oven door, 8-second oven door, 9-food intake , 10-switch mechanism, 11-slide, 12-cargo pallet, 13-discharge motor, 15-electronic touch screen;

[0032] 501-bracket, 502-ball screw, 503-push plate, 504-screw nut, 505-bearing, 506-gear, 507-Z-shaped plate, 508-reinforcing rib;

[0033] 601-Z-axis driving device, 602-manipulator tray, 603-vertical partition.

[0034] Embodiments of the present application will be described in detail below in conjunction with the accompanying drawings.

[0035] The new refrigerated box lunch automatic heating vending machine includes a vending machine 1 and a microwave oven 2. The vend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com