Automatic transfer switching device with re-trip function

A technology for automatic transfer switches and electrical appliances, applied in electrical switches, circuits, electrical components, etc., can solve the problems of increased power consumption of equipment, large resistance torque of the mechanism, unfavorable energy saving, etc., to prolong the service life of the mechanism, reduce the mechanical force, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

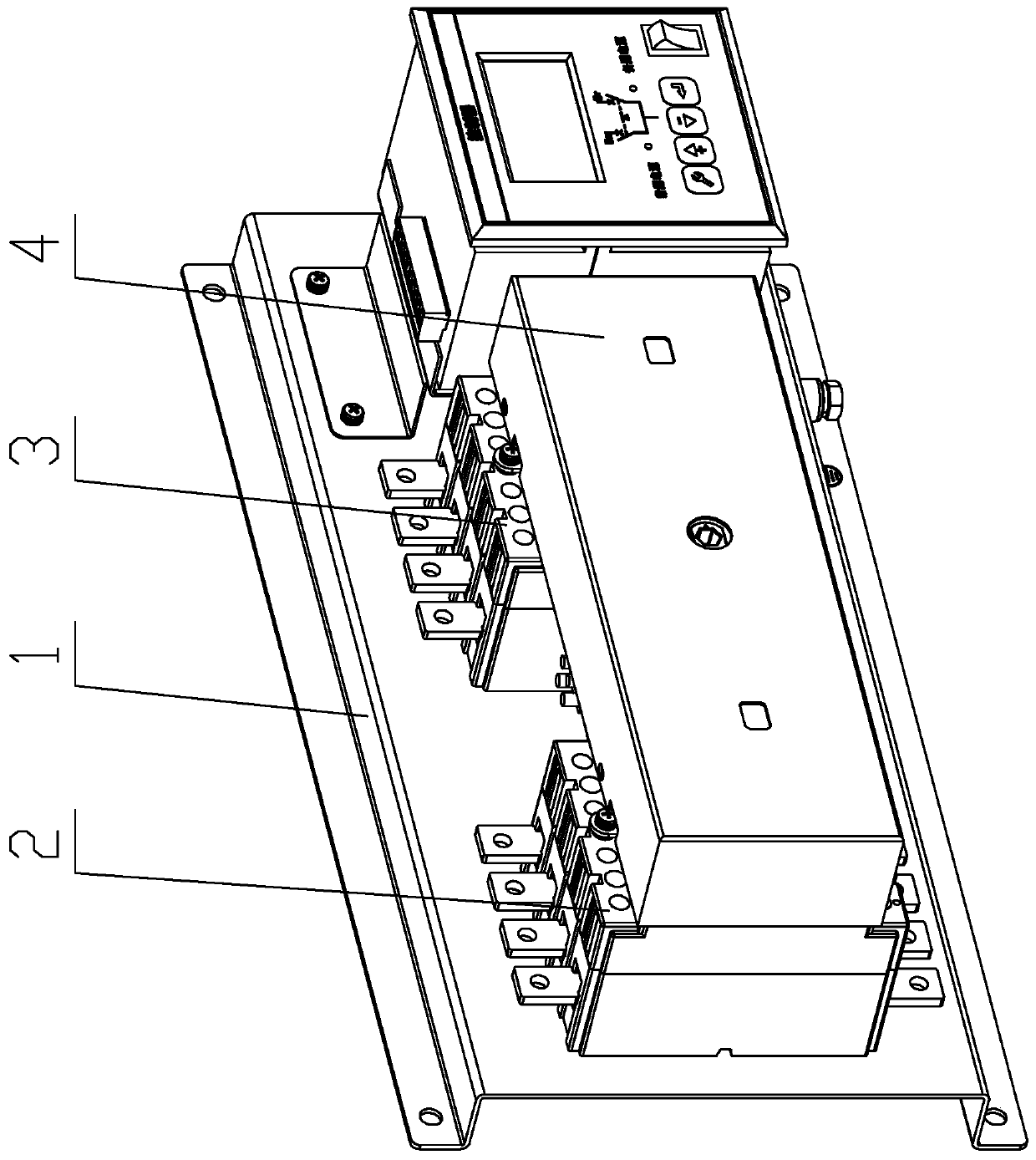

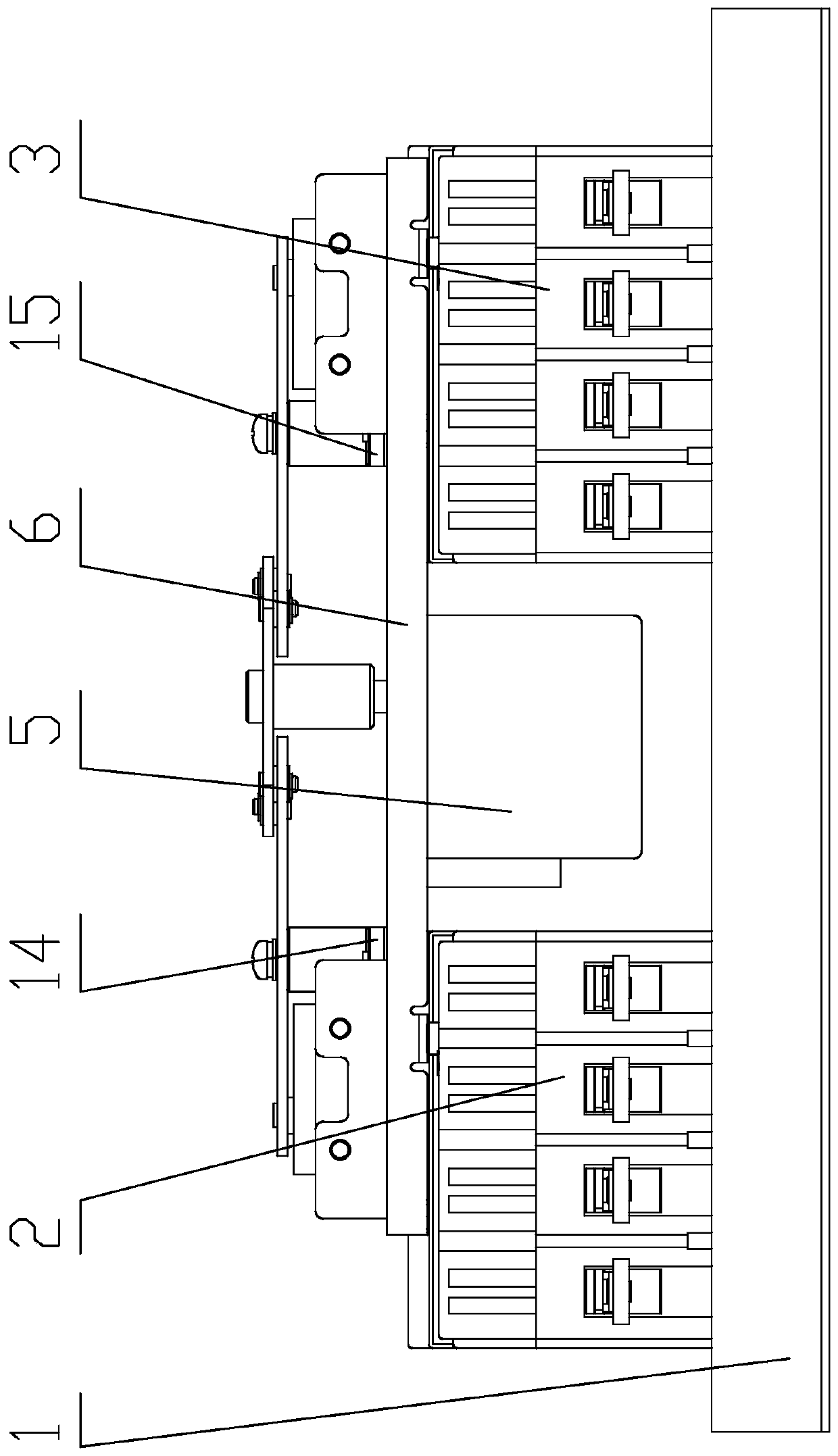

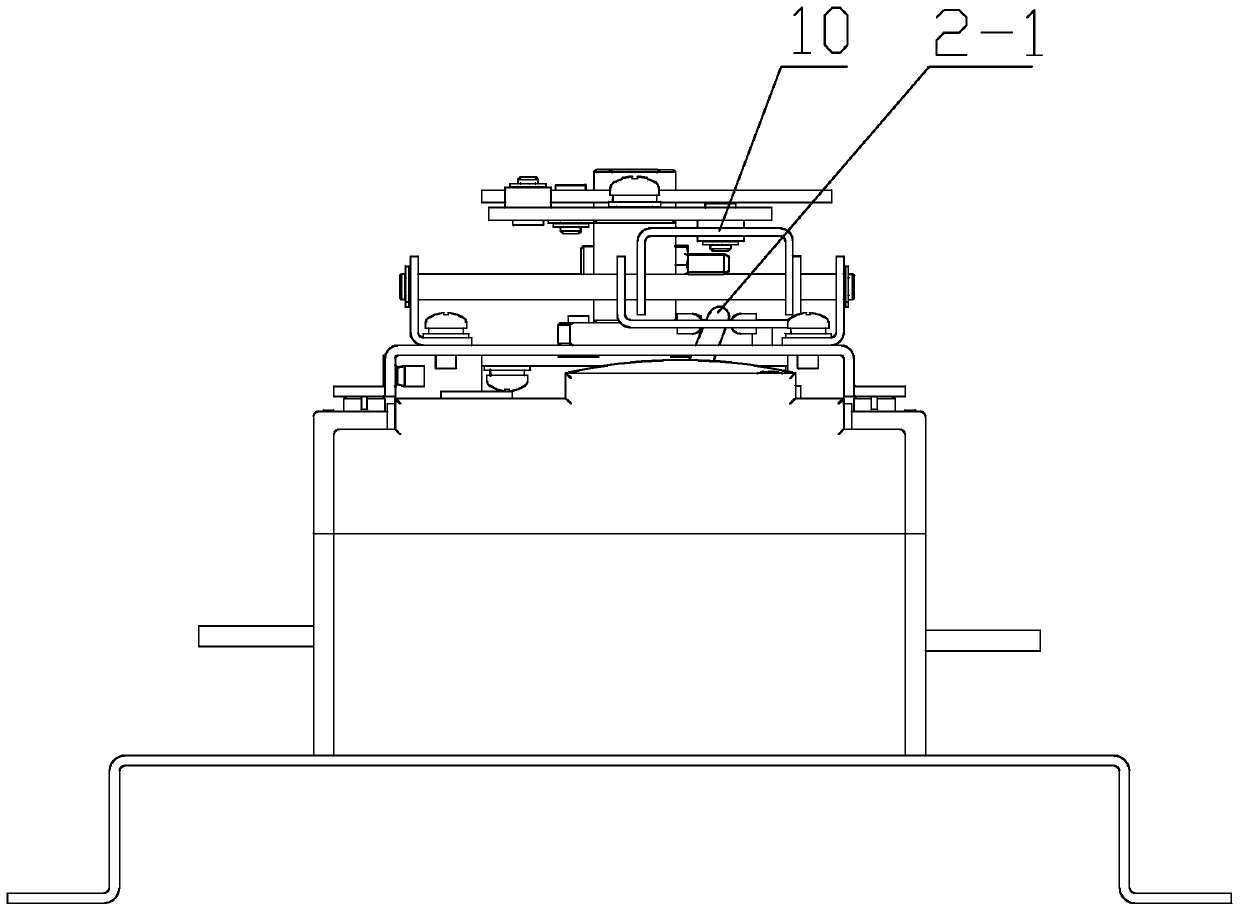

[0028] Figure 1-10 Including 1. Mounting plate, 2. Common power module, 2-1. Common power switch handle, 3. Spare power module, 3-1. Spare power switch handle, 4. Shell, 5. Motor, 6. Fixed plate , 7. Control wheel, 7-1. The first shaft of the control wheel, 7-2. The second shaft of the control wheel, 7-3. The common closing operation surface of the control wheel, 7-4. The spare closing operation surface of the control wheel, 7-5. Commonly used re-buckle operation boss of the control wheel, 7-6. Spare re-buckle operation boss of the control wheel, 7-7. The first limit slot of the control wheel, 7-8. The second limit slot of the control wheel, 8. Commonly used rocker arm, 8-1. Commonly used rocker arm first axis, 8-2. Commonly used rocker arm second axis, 8-3. Commonly used rocker arm long slot, 9. Spare rocker arm, 9-1. Spare rocker arm Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com