A shoe sole impurity removal machine

A technology for removing machine and impurities, applied in the field of cleaning machine, can solve the problems of labor and low work efficiency, and achieve the effect of high work efficiency and stable shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

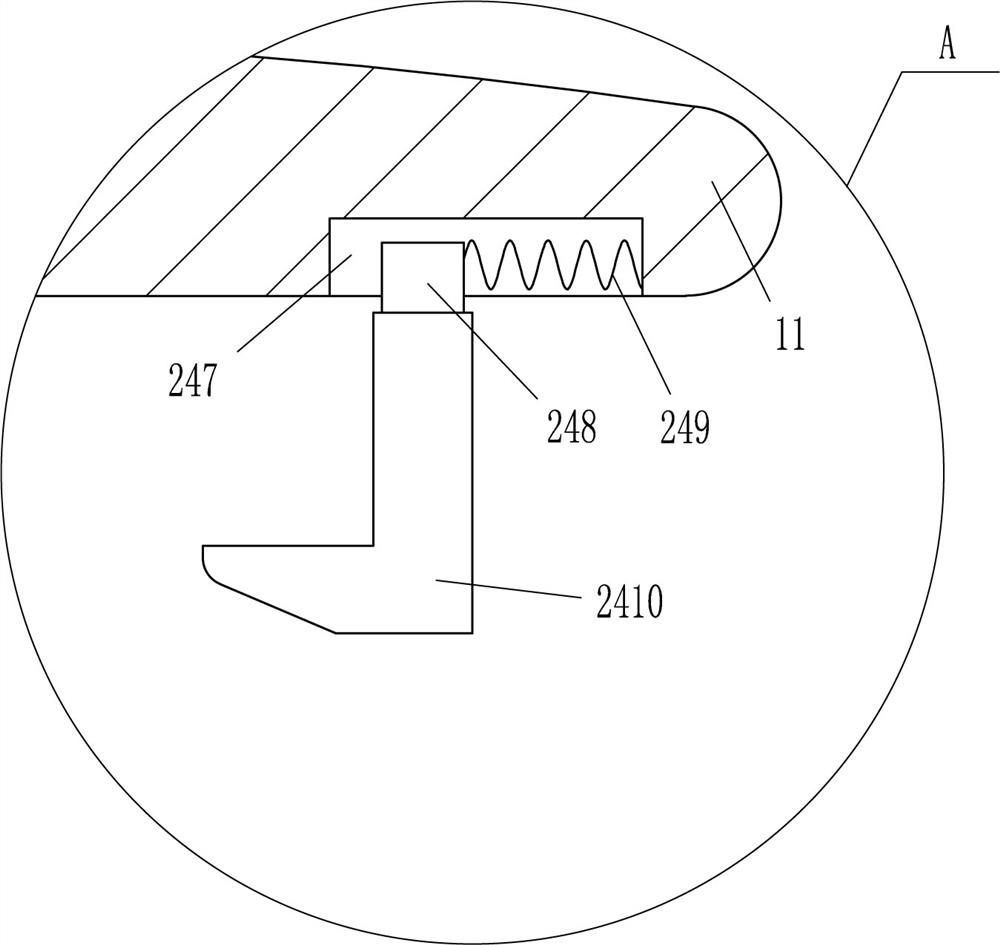

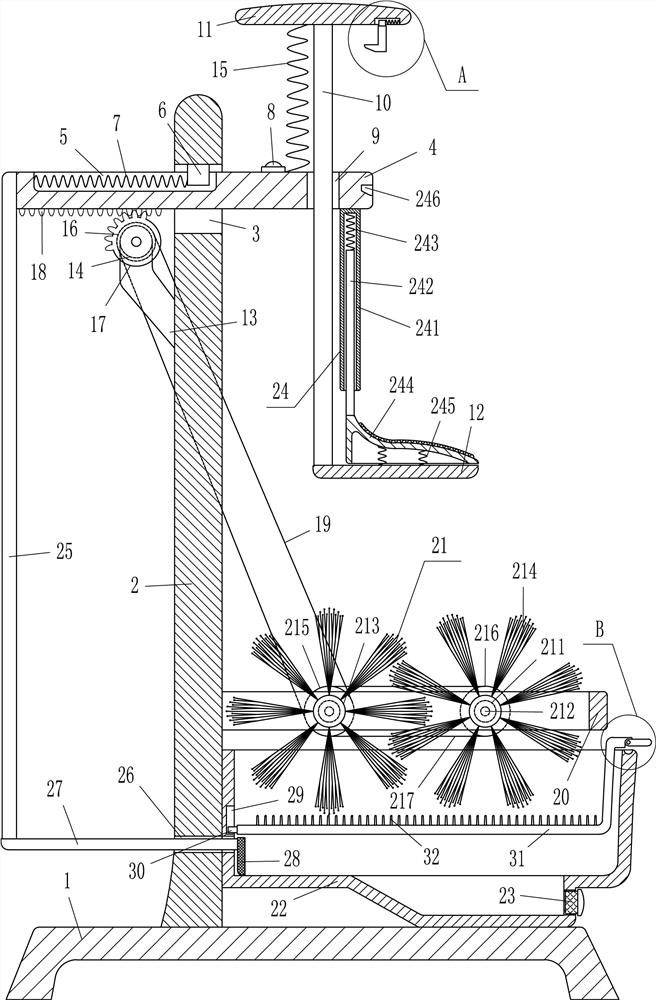

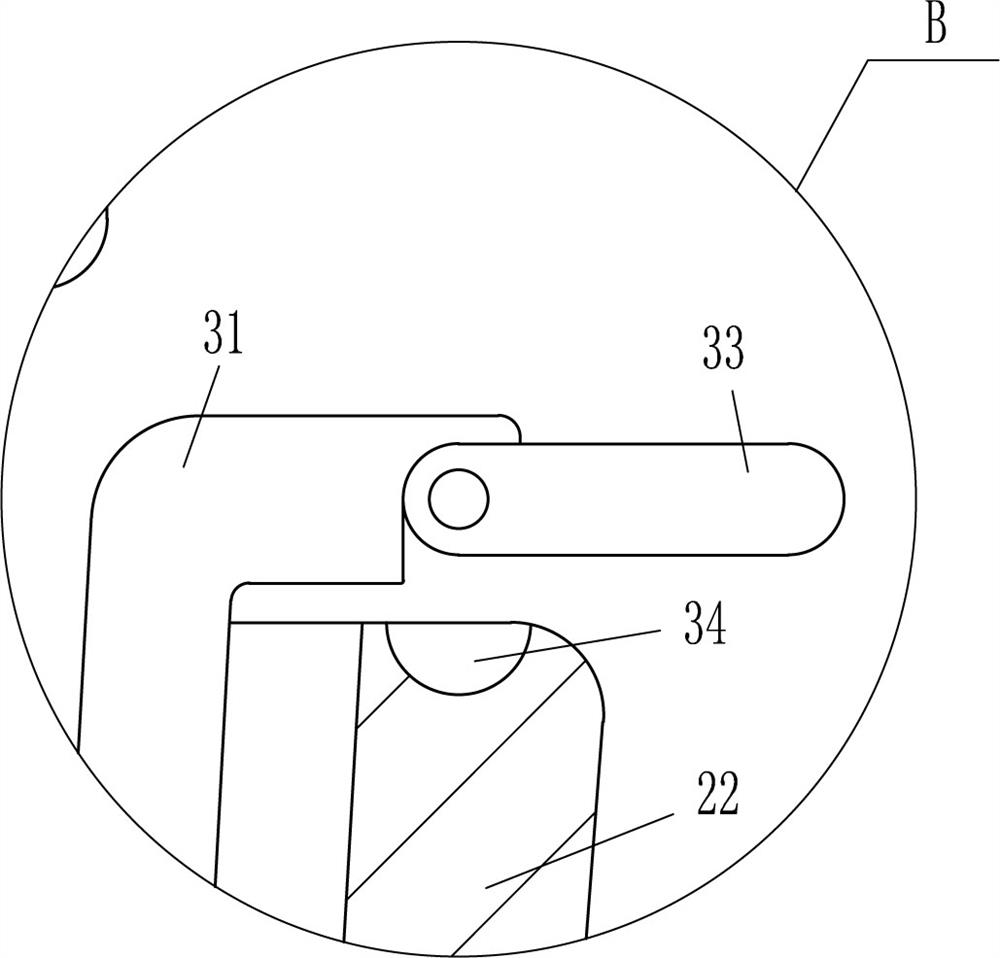

[0016] A shoe sole impurity removal machine, such as figure 1 As shown, it includes a base 1, a vertical plate 2, a movable plate 4, a horizontal slider 6, a first spring 7, a button 8, a guide rod 10, a push plate 11, a horizontal plate 12, a support plate 13, a driving motor 14, a first Two springs 15, the first pulley 16, sector gear 17, tooth block 18, the first flat belt 19, u-shaped plate 20, clearing device 21, frame body 22 and plug 23, vertical plate 2 is installed on the left side of base 1 top, The base 1 is connected with the vertical board 2 by means of bolt connection, the upper part of the vertical board 2 has a guiding through hole 3, the movable plate 4 is located in the through hole 3 to cooperate with it, and the left side of the top of the movable board 4 has a guiding function Horizontal chute 5, the sliding type in horizontal chute 5 is provided with horizontal slider 6, horizontal slider 6 is slidingly matched with horizontal chute 5, the top of horizont...

Embodiment 2

[0018] A shoe sole impurity removal machine, such as figure 1 As shown, it includes a base 1, a vertical plate 2, a movable plate 4, a horizontal slider 6, a first spring 7, a button 8, a guide rod 10, a push plate 11, a horizontal plate 12, a support plate 13, a driving motor 14, a first Two springs 15, the first pulley 16, sector gear 17, tooth block 18, the first flat belt 19, u-shaped plate 20, clearing device 21, frame body 22 and plug 23, vertical plate 2 is installed on the left side of base 1 top, The upper part of the vertical plate 2 has a guiding through hole 3, and the movable plate 4 is located in the through hole 3 to cooperate with it. The left side of the top of the movable plate 4 has a guiding horizontal chute 5, and the sliding type in the horizontal chute 5 A horizontal slider 6 is provided, and the horizontal slider 6 is slidingly matched with the horizontal chute 5. The top of the horizontal slider 6 is fixedly connected to the top of the through hole 3, ...

Embodiment 3

[0021] A shoe sole impurity removal machine, such as Figure 1-2 As shown, it includes a base 1, a vertical plate 2, a movable plate 4, a horizontal slider 6, a first spring 7, a button 8, a guide rod 10, a push plate 11, a horizontal plate 12, a support plate 13, a driving motor 14, a first Two springs 15, the first pulley 16, sector gear 17, tooth block 18, the first flat belt 19, u-shaped plate 20, clearing device 21, frame body 22 and plug 23, vertical plate 2 is installed on the left side of base 1 top, The upper part of the vertical plate 2 has a guiding through hole 3, and the movable plate 4 is located in the through hole 3 to cooperate with it. The left side of the top of the movable plate 4 has a guiding horizontal chute 5, and the sliding type in the horizontal chute 5 A horizontal slider 6 is provided, and the horizontal slider 6 is slidingly matched with the horizontal chute 5. The top of the horizontal slider 6 is fixedly connected to the top of the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com