Scrap copper collecting device for copper bar wire drawing machine

A copper rod wire drawing machine and collection device technology, applied in grinding/polishing safety devices, presses, metal processing equipment and other directions, can solve problems affecting the normal operation of copper rod wire drawing dies, etc., achieve a simple and fast removal process and reduce labor Strength, the effect of reducing the number of times to remove copper scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

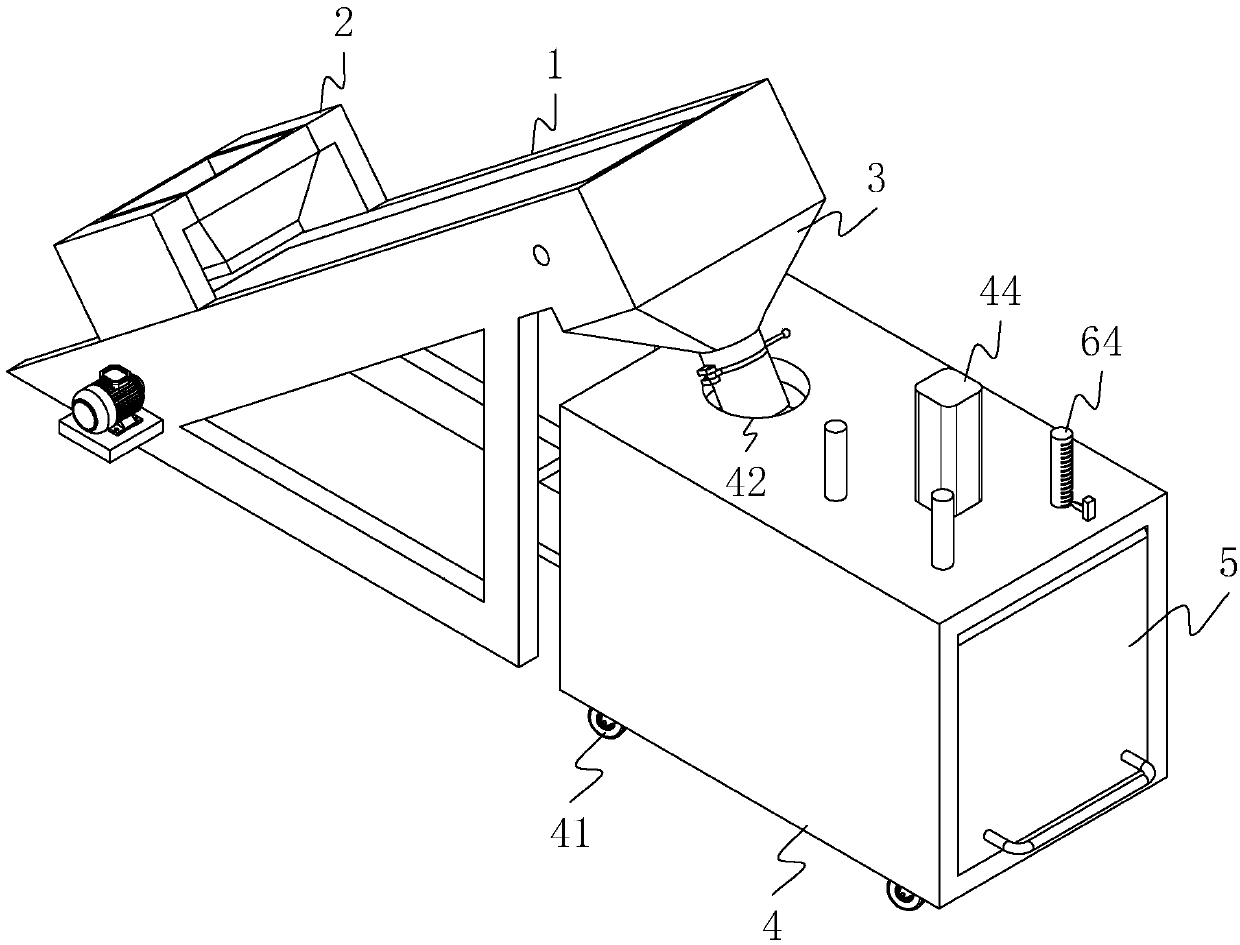

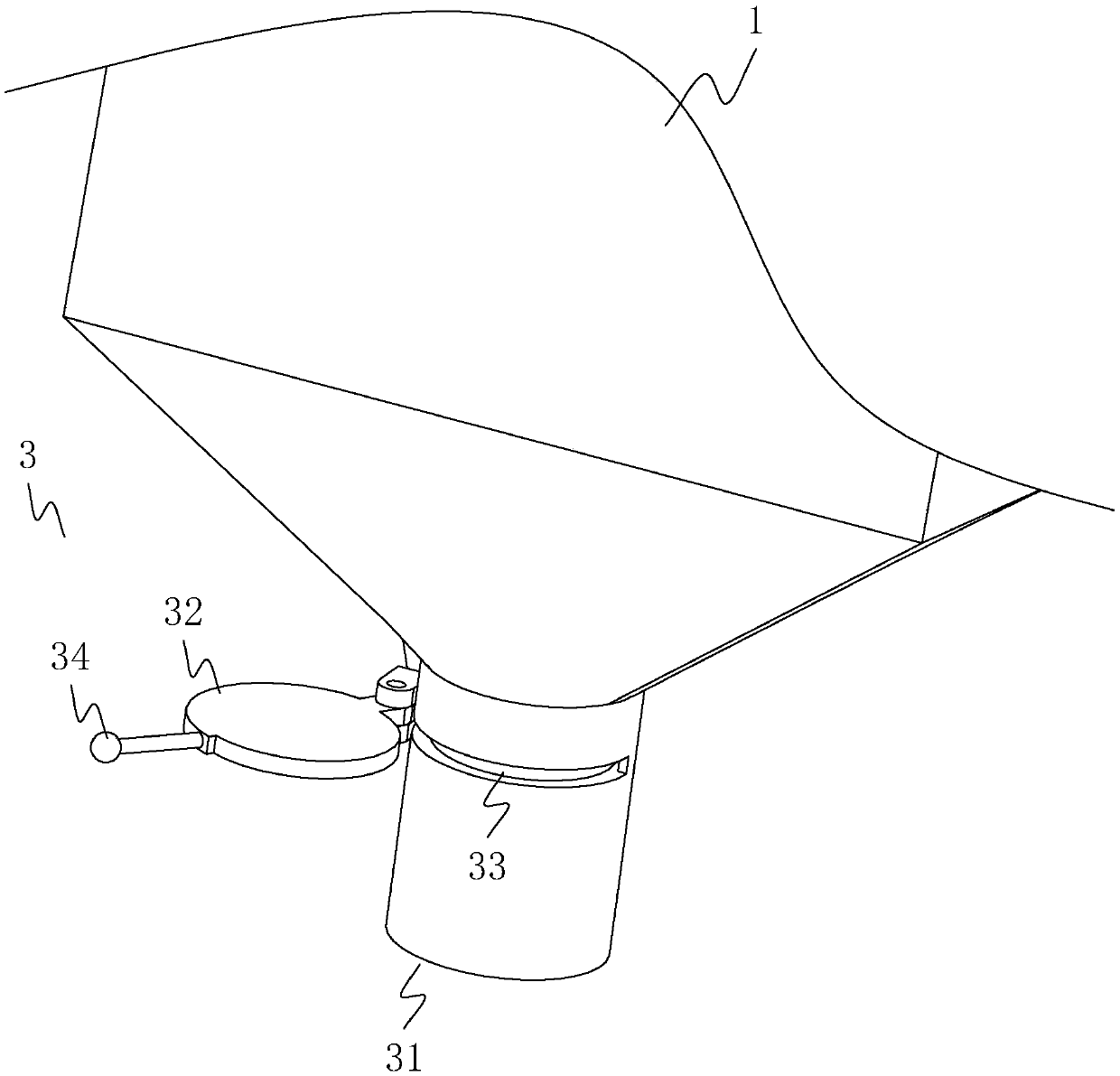

[0035] A copper rod drawing machine waste miscellaneous copper collection device, such as figure 1 , figure 2As shown, it includes a conveyor belt 1 arranged obliquely, a feed chute 2 arranged at the lower end of the conveyor belt 1 and a discharge chute 3 arranged at the upper end of the conveyor belt 1 . The discharge chute 3 comprises a tank body 31, a limiting plate 32 hinged to the side wall of the lower end of the tank body 31, the outer wall of the tank body 31 is provided with a limiting groove 33 for the sliding insertion of the limiting plate 32, and the outer wall of the limiting plate 32 is provided with There is a handle 34 .

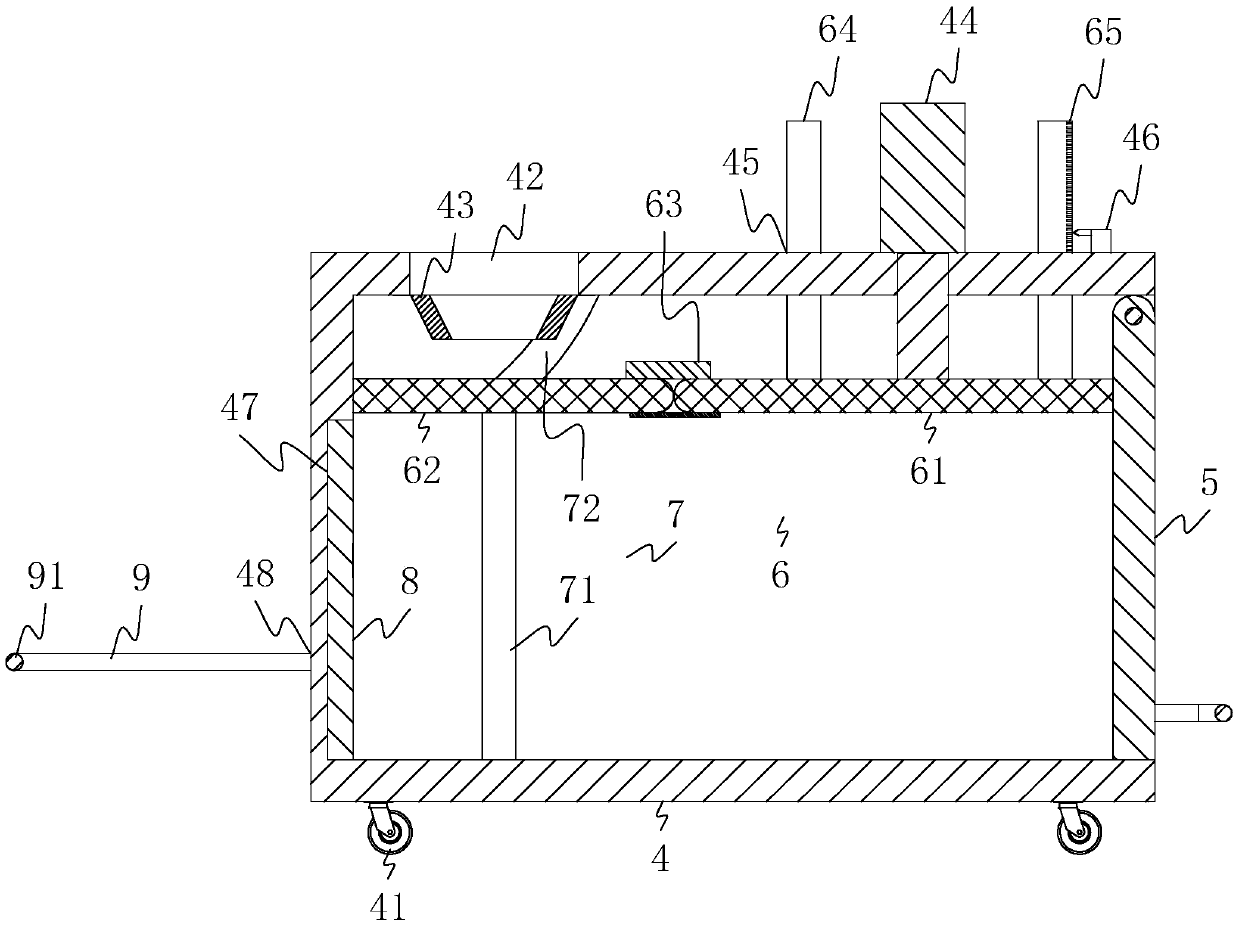

[0036] Such as figure 1 , image 3 As shown, the device also includes a material storage box 4, a box door 5 arranged on the side wall of the material storage box 4, the lower end surface of the material storage box 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com