Sewing machine capable of cleaning material flocks

A sewing machine and batting technology, which is used in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of batting accumulation and blockage, reducing the flexibility between transmissions, and transmission jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

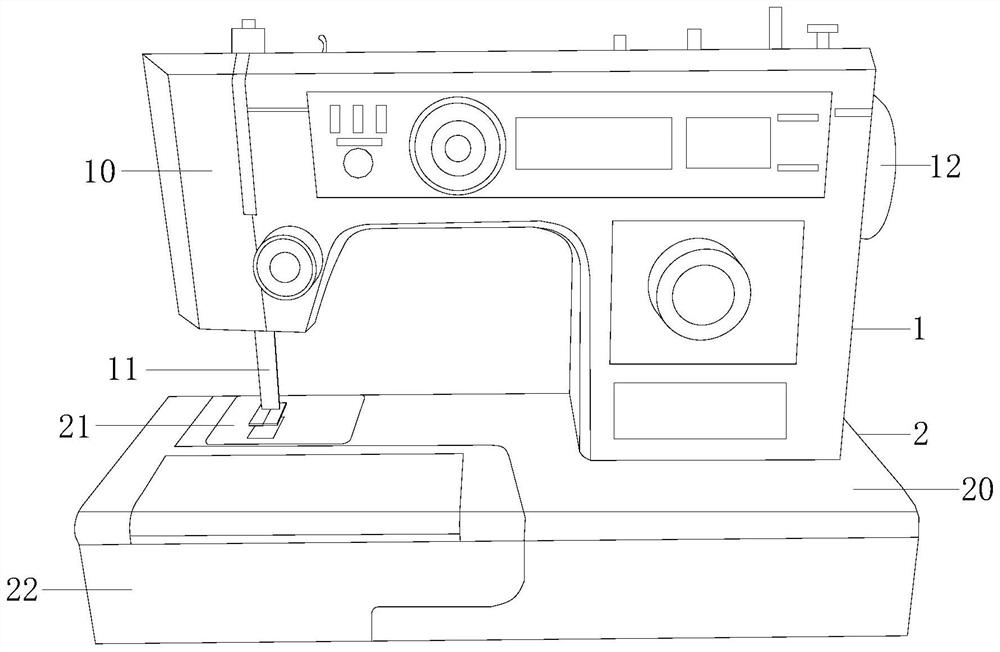

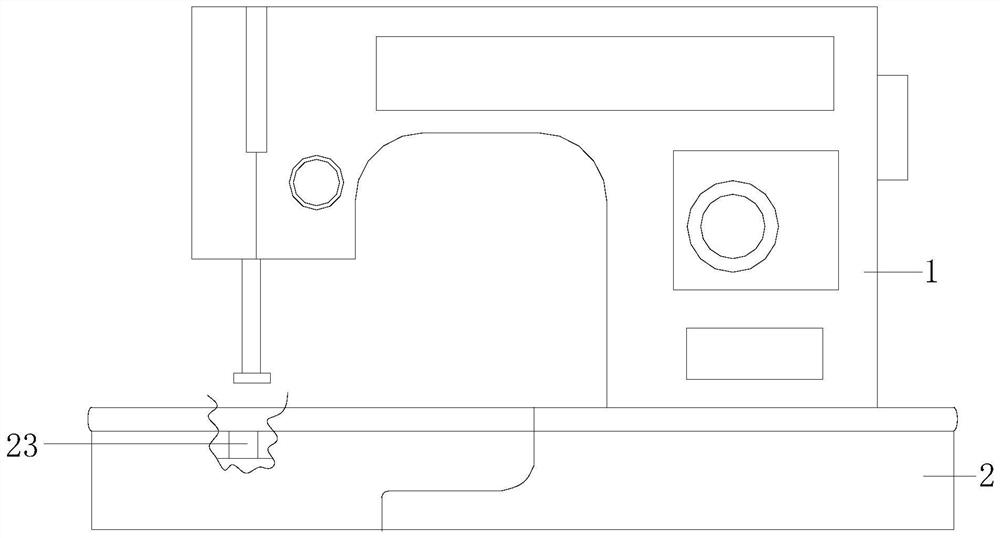

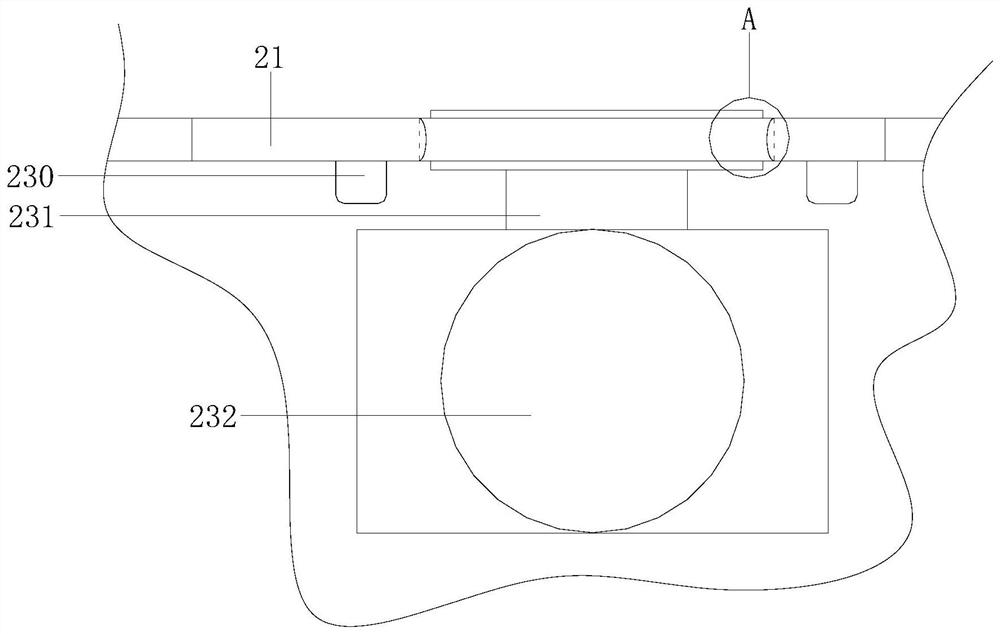

[0027] Example 1 see Figure 1-6 , the present invention provides a sewing machine technical solution for cleaning wadding: its structure includes a machine head 1 and a machine base 2, the machine head 1 is installed on the machine base 2, and the machine head 1 includes a machine head body 10, a presser foot 11. Rotary valve 12, the presser foot 11 is installed on the machine head body 10, the machine head body 10 is equipped with a rotary valve 12, the machine base 2 is composed of the machine base body 20, the mounting plate 21, the machine side cover 22. The shuttle structure 23 is composed of the base body 20 and the machine side cover 22. The mounting panel 21 is matched with the base body 20. The shuttle structure 23 is installed on the base body 20 and Below the presser foot 11, the shuttle structure 23 includes a cleaning structure 230, a plate presser 231, and a shuttle shuttle 232. The plate presser 231 makes a slight lifting action to assist the movement of the cl...

Embodiment 2

[0029] Example 2 see Figure 7 , 8 , the present invention provides a sewing machine technical solution for cleaning lint: the cleaning structure 230 includes a double track 2300, an air injector 2301, and an air extractor 2302; connect.

[0030] When the cleaning structure 230 is running, the air jet 2301 sprays air, and the fluff is then collected by the air extractor 2302, so that the fluff can be cleaned and collected in a small amount in time, and the staff will disassemble and assemble the parts in a later stage to process the floc.

[0031] Compared with the prior art, the technical progress of the present invention is: the plate presser 231 moves while the air delivery device 211 sends gas to prevent the material fluff from entering the gap between the plate presser 231 and the mounting plate 21, and the cleaning structure 230 passes through the air injector 2301, The air extractor 2302 cleans the lint at the shuttle in time to ensure that the flexibility of each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com