Method for preparing lithium-rich solution and manganese dioxide by using spent lithium manganese phosphate

A technology of lithium manganese phosphate and manganese dioxide, applied in manganese oxide/manganese hydroxide, recycling technology, lithium carbonate;/acid carbonate, etc., can solve problems such as limiting battery energy density and achieve shortening Cleaning time, achieving recycling, avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

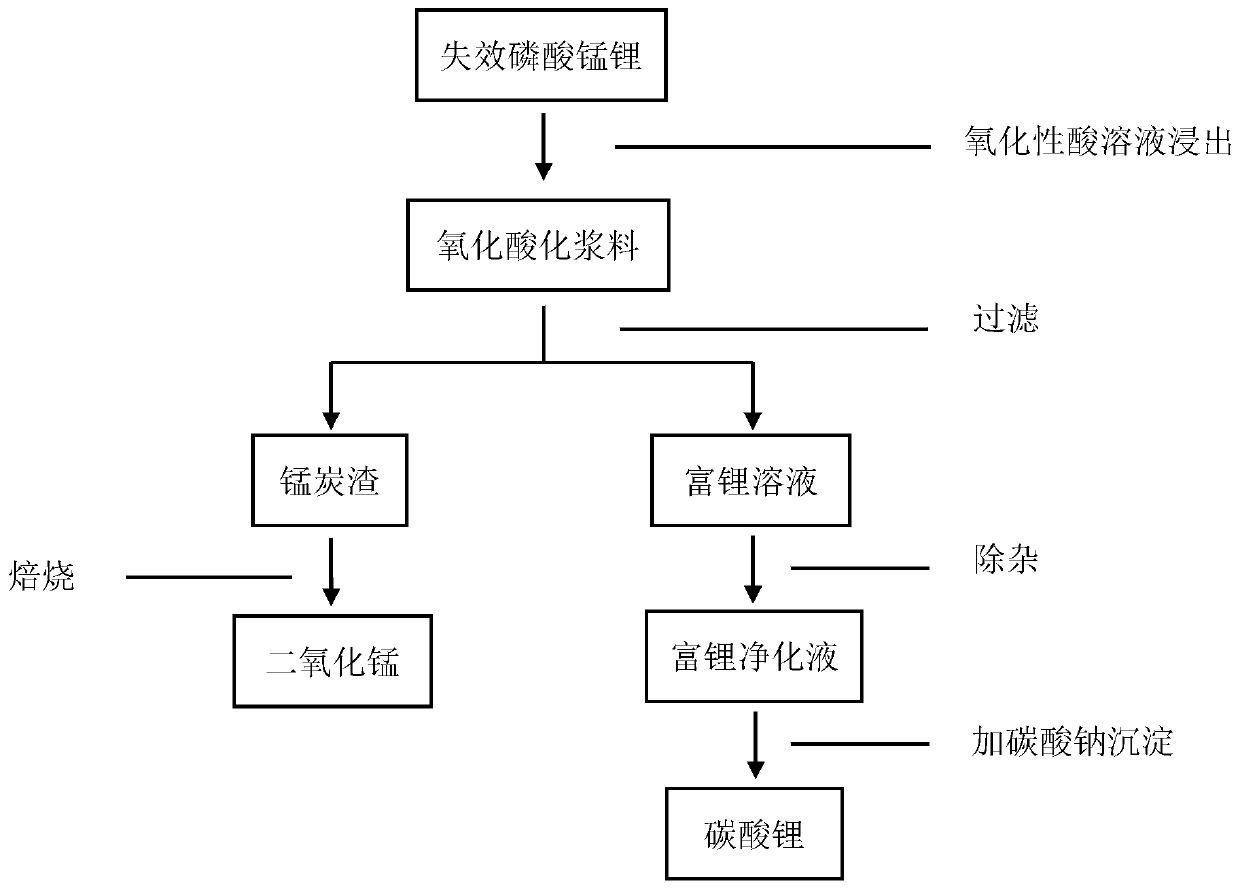

[0022] Such as figure 1 As shown, first dissolving the invalid lithium manganese phosphate in the sodium persulfate solution, the oxidative acidification slurry is obtained through the oxidation reaction; then the lithium-rich solution and the manganese carbon residue are obtained through filtration, and the manganese carbon residue is a mixture of manganese dioxide and carbon; The lithium-rich solution is purified to obtain a lithium-rich purification solution, and the lithium-rich purification solution is precipitated with a sodium carbonate solution to obtain lithium carbonate; the manganese carbon residue is roasted at 750°C in an oxygen atmosphere to obtain manganese dioxide. The impurity removal operation is to use sodium hydroxide to adjust the pH value of the lithium-rich solution to 8 to remove a small amount of manganese ions, and then use sodium hydroxide to adjust the pH value to 11.

Embodiment 2

[0024] Such as figure 1 As shown, first dissolving the invalid lithium manganese phosphate in the sodium persulfate solution, the oxidative acidification slurry is obtained through the oxidation reaction; then the lithium-rich solution and the manganese carbon residue are obtained through filtration, and the manganese carbon residue is a mixture of manganese dioxide and carbon; The lithium-rich solution is purified to obtain a lithium-rich purified solution, and the lithium-rich purified solution is precipitated with a sodium carbonate solution to obtain lithium carbonate; the manganese carbon residue is roasted at 700°C in an oxygen atmosphere to obtain manganese dioxide. The impurity removal operation is to use sodium hydroxide to adjust the pH value of the lithium-rich solution to 8 to remove a small amount of manganese ions, and then use sodium hydroxide to adjust the pH value to 11.

Embodiment 3

[0026] Such as figure 1 As shown, first dissolving the invalid lithium manganese phosphate in the sodium persulfate solution, the oxidative acidification slurry is obtained through the oxidation reaction; then the lithium-rich solution and the manganese carbon residue are obtained through filtration, and the manganese carbon residue is a mixture of manganese dioxide and carbon; The lithium-rich solution is purified to obtain a lithium-rich purified solution, and the lithium-rich purified solution is precipitated with a sodium carbonate solution to obtain lithium carbonate; the manganese carbon residue is roasted at 700°C in an oxygen atmosphere to obtain manganese dioxide. The impurity removal operation is to use sodium hydroxide to adjust the pH value of the lithium-rich solution to 8 to remove a small amount of manganese ions, and then use sodium hydroxide to adjust the pH value to 11.

[0027] The oxidation reaction is completed in a stainless steel container. After the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com