Steel wire rope hoisting system for crane

A lifting system and lifting wire rope technology, applied in the direction of load block, clockwork mechanism, load hanging components, etc., can solve the problem that the running speed of the trolley cannot reach the full speed state, the spreader does not have the micro-positioning function, and affects the whole To solve problems such as machine operation efficiency, achieve obvious anti-rolling effect, high precision of grabbing and placing boxes, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

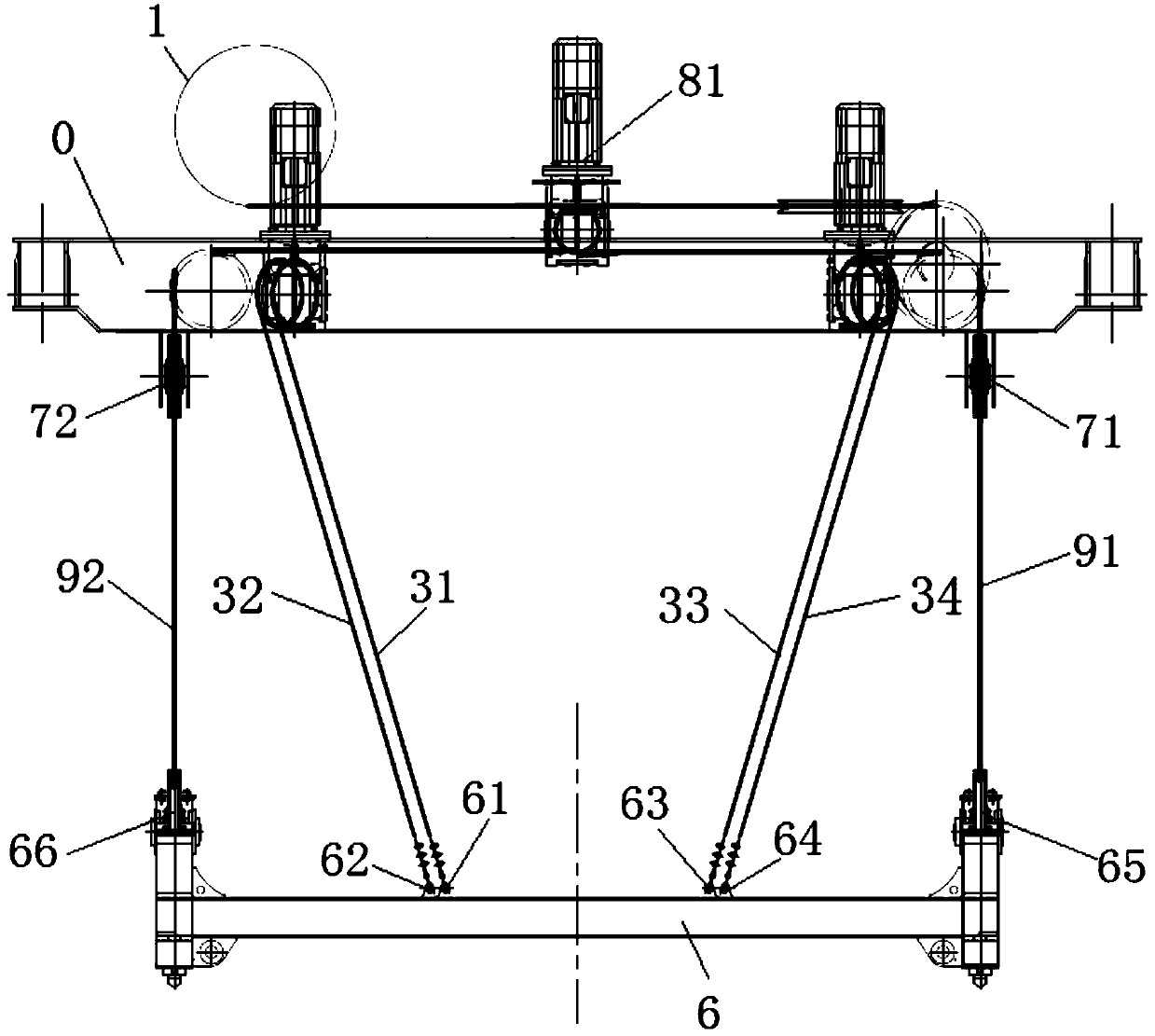

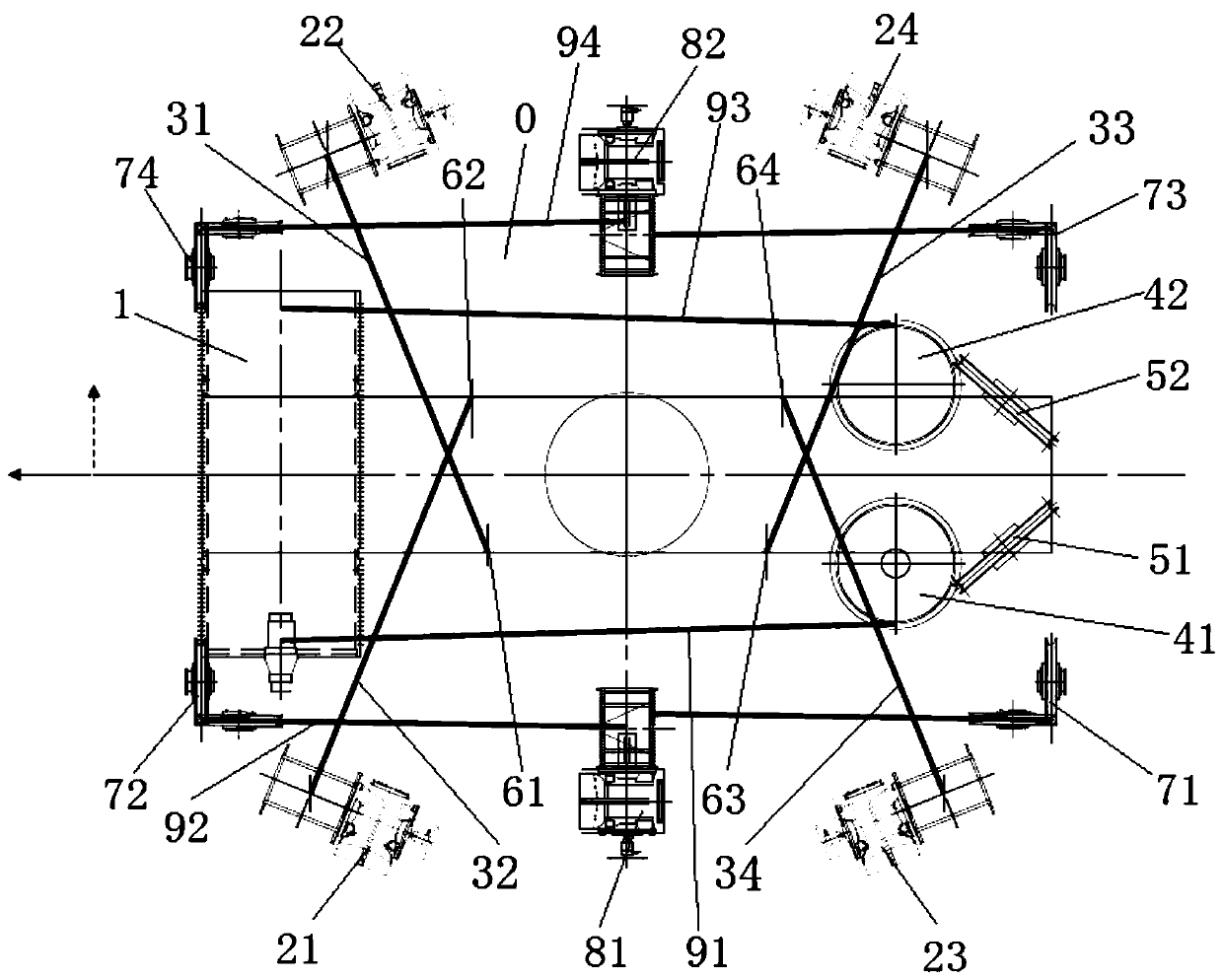

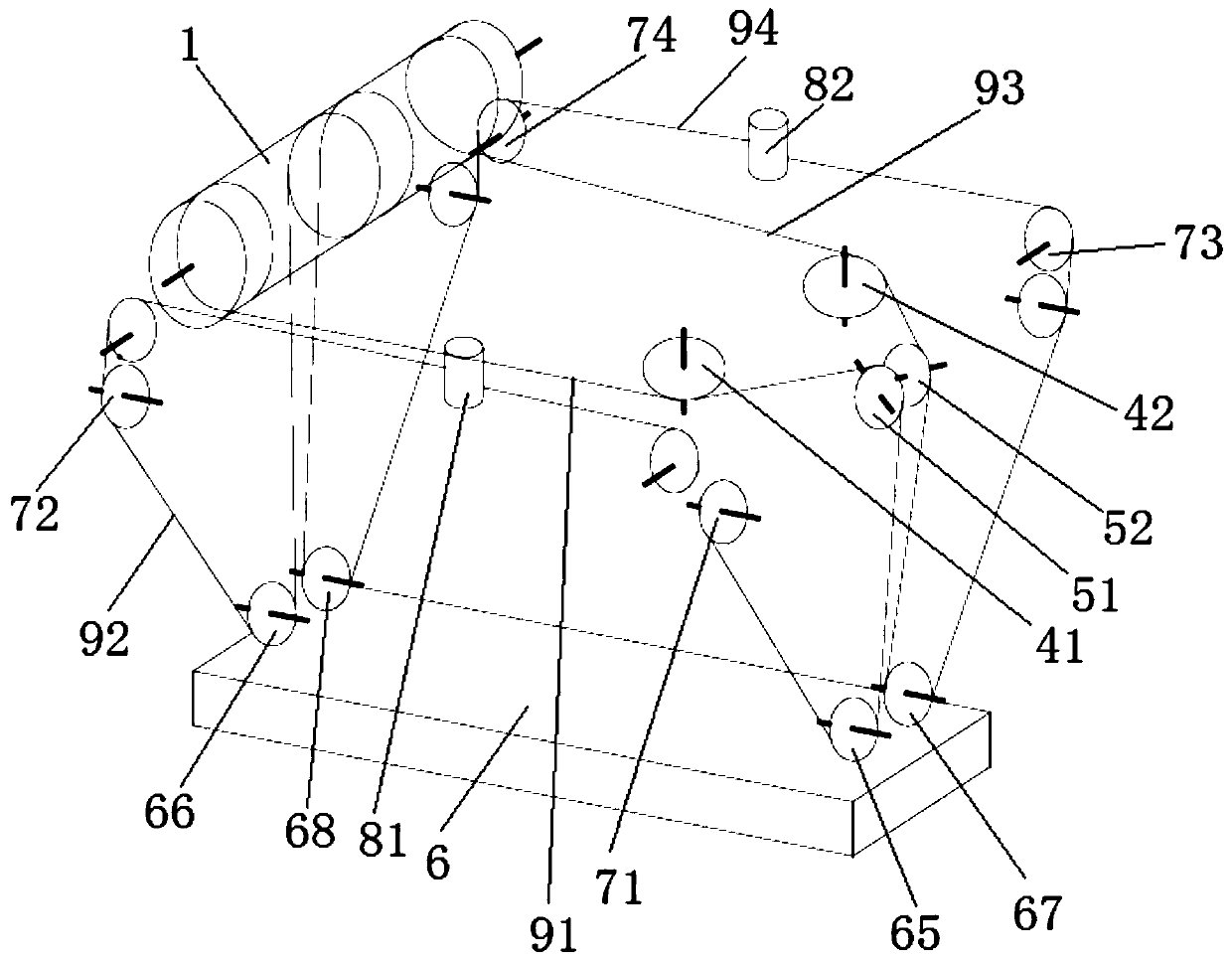

[0050] Such as Figure 1-2 As shown, a wire rope hoisting system for a crane includes a trolley frame 0 and a spreader upper frame 6, and the spreader upper frame 6 is located at the bottom of the trolley frame 0; a lifting drum is fixedly arranged on the trolley frame 0 1. The hoisting drum 1 is wound with a hoisting wire rope, and the free end of the hoisting wire rope passes through the trolley frame 0 and is fixedly connected to the hanger upper frame 6. The hoisting drum 1 is provided with a driving mechanism, and the driving mechanism Drive the hoisting drum 1 to rotate, so that the hoisting wire rope wound on the hoisting drum is locked or loosened, so as to realize the corresponding lifting or lowering action of the spreader;

[0051] An anti-sway reel is respectively arranged at the four corners of the upper surface of the trolley frame 0, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com