Automatic cleaning technique of dust collection tube of dust removing system

A dust removal system and automatic cleaning technology, applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve problems such as dust accumulation in pipelines, paralysis of dust removal pipe network operation, and inability to ensure the operation of dust removal system, etc., to achieve the elimination of asthma The effect of vibration and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is a detailed introduction to the automatic cleaning process of the dust accumulation pipeline of the dust removal system of the present invention in conjunction with the accompanying drawings:

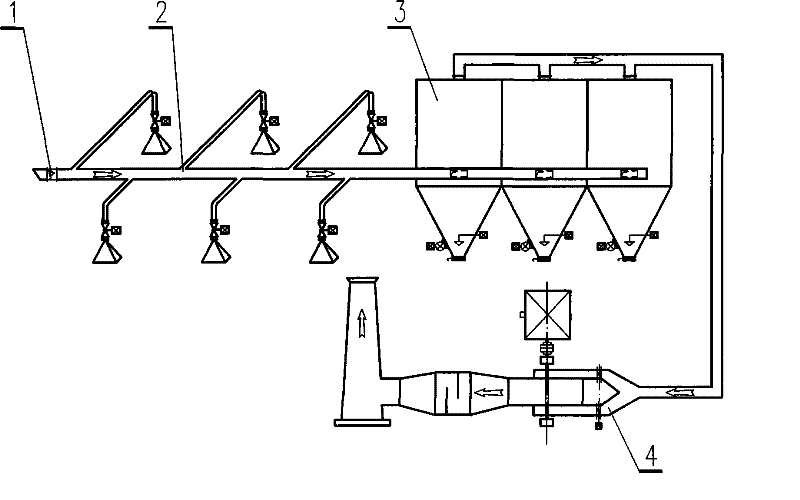

[0012] See figure 1 , Dust removal system dust pipeline automatic cleaning process, the process is composed of balance flap valve 1, dust removal pipe network unit 2, flue gas purification unit 3 and clean gas discharge unit 4. The balance flap valve 1 described therein is a single device; the dust removal pipe network unit 2 is composed of various dust removal suction hoods, electric valves, etc.; the flue gas purification unit 3 is composed of various types of flue gas purification final products; the net gas discharge Unit 4 is composed of fan, muffler, chimney and corresponding connecting components.

[0013] See figure 1 , the balance flap valve 1 is located at the end of the dust removal pipe network unit 2, one end is connected to the outdoor atmosphere t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com