A horizontal oil-free screw vacuum pump with overpressure exhaust function

A vacuum pump and screw technology, which is used in rotary piston pumps, components of pumping devices for elastic fluids, and rotary piston/oscillating piston pump components, which can solve the problems of prolonged pumping time, pumping speed and Reduce the ultimate vacuum degree, reduce the pumping efficiency and other problems, to achieve the effect of shortening the pumping time, improving the energy saving effect, and reducing the exhaust power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

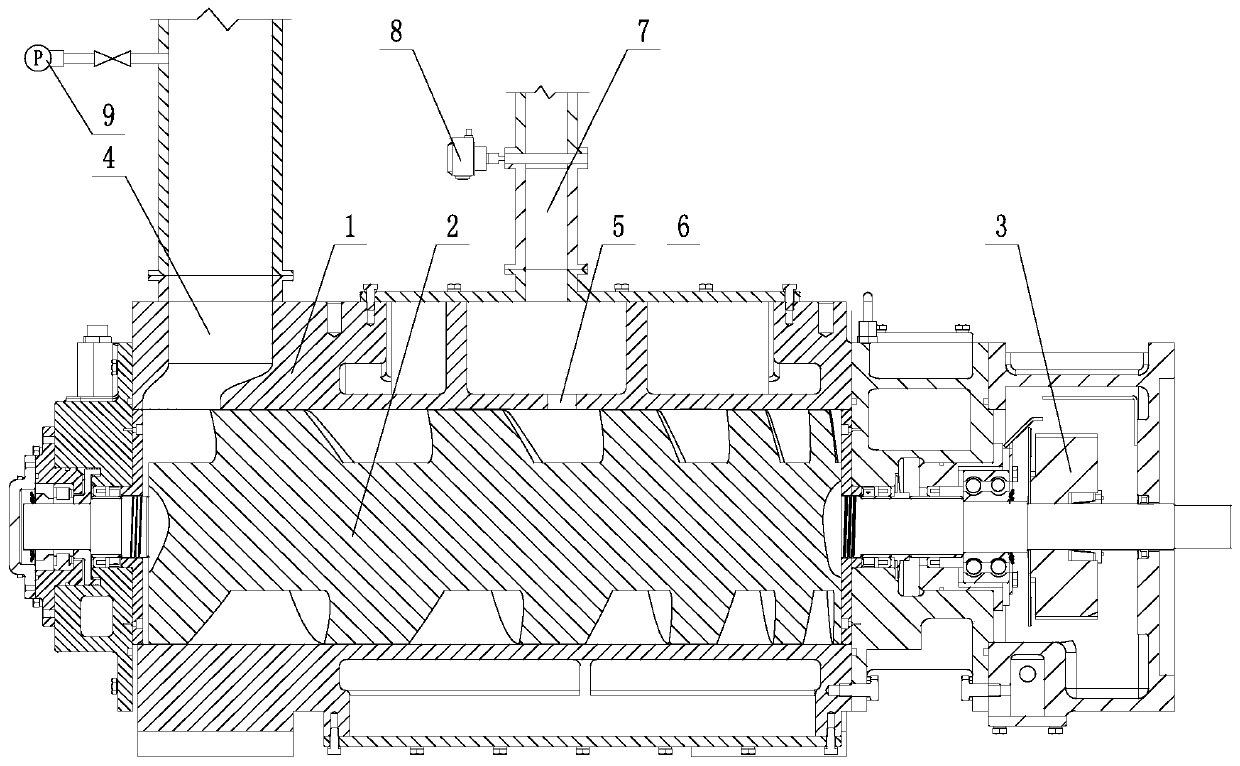

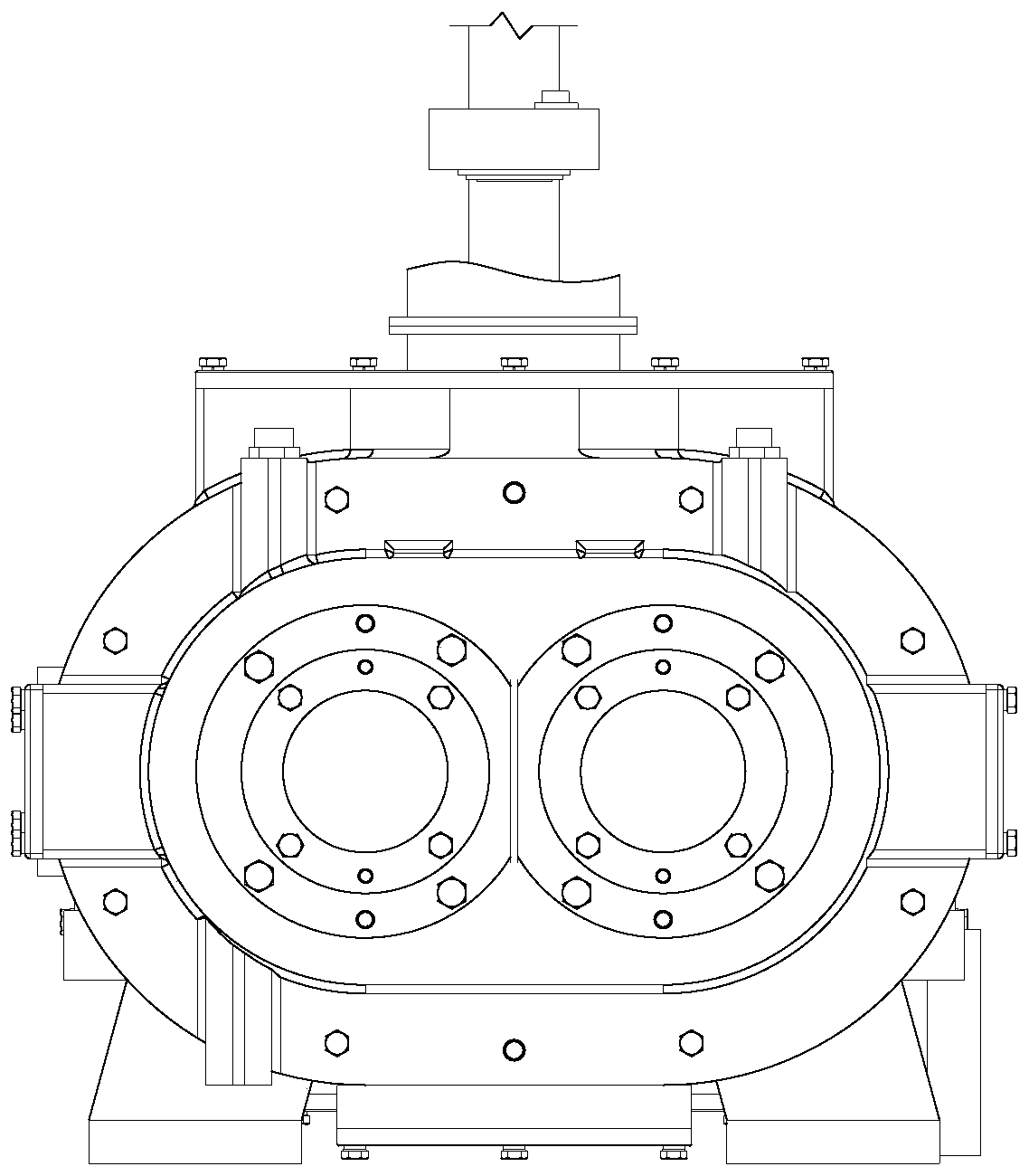

Embodiment 1

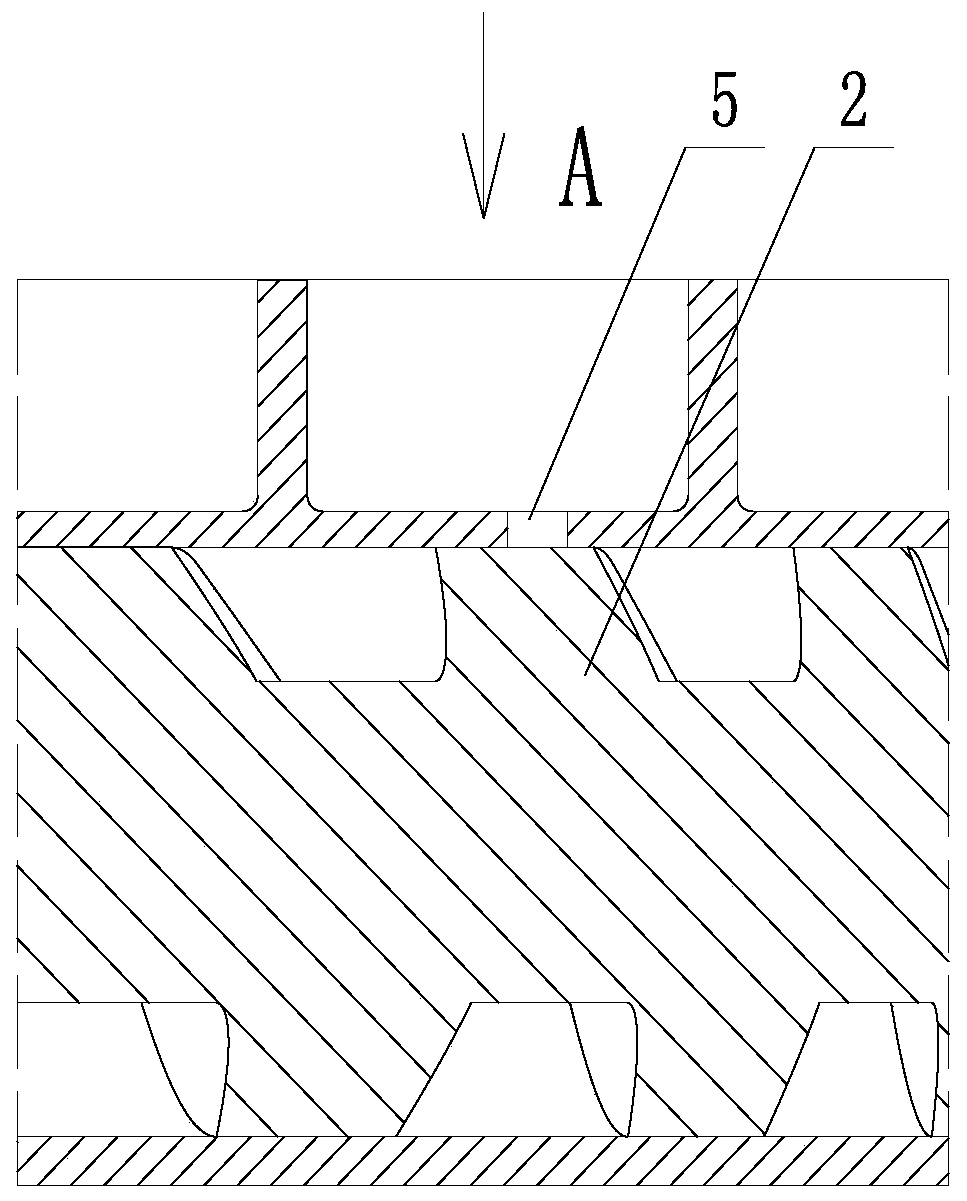

[0048] Such as Figure 1~6 As shown, in this embodiment, the screw rotor 2 is a one-stage variable-pitch screw with equal cross-section, and the screw lead of the screw rotor 2 decreases linearly along the axial direction from the suction port 4 to the exhaust port of the pump body 1, and the compression of the screw vacuum pump The ratio R is set to 5, and the opening position of the pressure relief hole 5 satisfies V m =V in / 5 1 / 2 ,, the shape of the pressure relief hole 5 is a circular hole, and the number of each group of pressure relief holes 5 is 4 (the total number of two groups of pressure relief holes 5 is 8), and the pressure relief valve 8 adopts an automatic control vacuum shut-off valve, Specifically, a GID type electric vacuum butterfly valve is selected, and the pressure relief pipe 7 communicates with the exhaust channel of the pump body through the pressure relief valve 8, and a pressure sensor 9 is installed at the suction port 4 of the pump body 1.

[00...

Embodiment 2

[0051] Such as Figure 7-12 As shown, in this embodiment, the screw rotor 2 is a three-stage variable-pitch screw with equal cross-section, and the screw lead of the screw rotor 2 gradually decreases in three stages along the axial direction from the suction port 4 to the exhaust port of the pump body 1. In addition, the suction section, compression section and exhaust section of the screw rotor 2 are equal-pitch sections with successively smaller screw leads, the compression ratio R of the screw vacuum pump is set to 4, and the opening position of the pressure relief hole 5 satisfies V in / V m = 2, the shape of the pressure relief hole 5 is a slit hole, the number of each group of pressure relief holes 5 is 2 (the total number of two groups of pressure relief holes 5 is 4), and the pressure relief valve 8 adopts a manually controlled vacuum stop valve , specifically select the GU type manual vacuum ball valve, the pressure relief pipe 7 is directly connected to the atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com