Electronic scale system capable of running

A technology for electronic scales and operating equipment, applied in the field of electronic scales, can solve the problems of increasing construction costs, failing to achieve horizontal changes in electronic scales, unfavorable electronic scales to reduce errors, etc., achieving reduced construction costs, favorable structure, and easy execution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with examples.

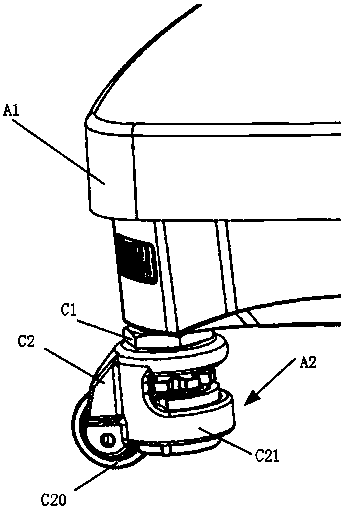

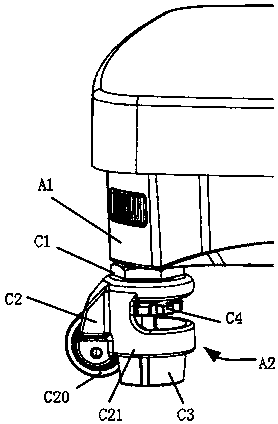

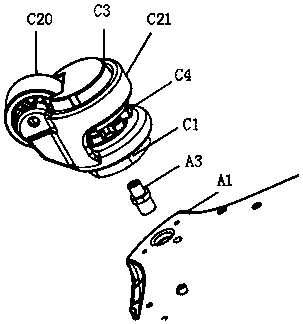

[0020] Such as Figure 1-Figure 4 As shown, the operable electronic scale system of this embodiment includes electronic scale A1 and operating equipment A2, operating equipment A2 is composed of several balls, the structure of the balls can be several contours, and its rotating section C20 can be a ring-shaped body or ring body;

[0021] The supporting frame C1 of the ball is connected to the electronic scale A1 through the positioning connection section A3. The positioning connection section A3 is a lead screw, one end of which is a tightening screw D1, and the other end is equipped with an ordinary screw D2; , Screw in the ordinary lead screw of the positioning coupling section A3 and position it on the support frame C1, then connect and rotate the balls with the positioning coupling section A3, so that the tensioning screw is screwed into the wire groove of the electronic scale A1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com