Hydraulic support testing device

A technology of hydraulic support and test device, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, testing of mechanical parts, etc. performance and stability, and the inability to perform compound loading tests of hydraulic supports with large inclination angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] For ease of understanding, the hydraulic support test device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

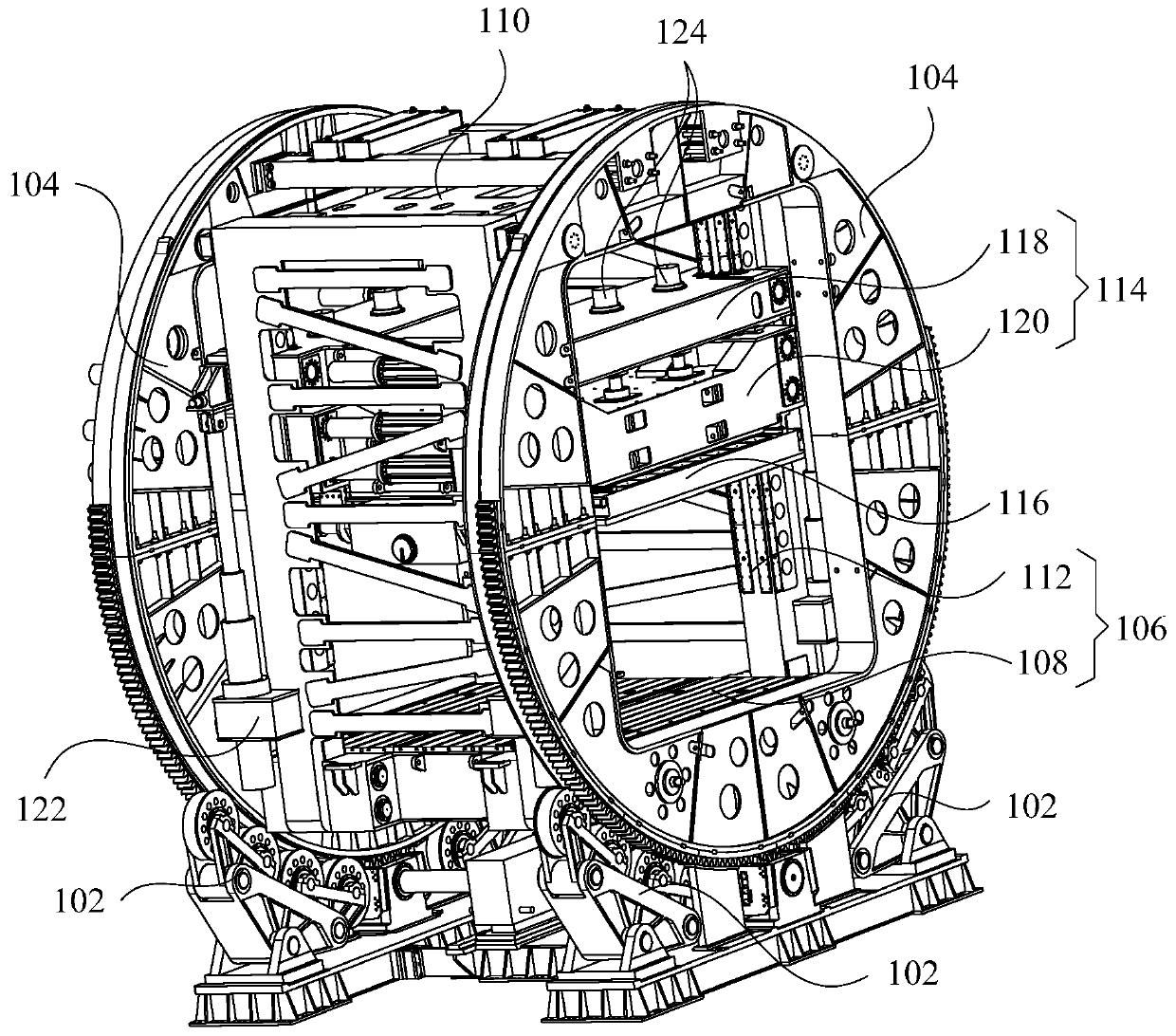

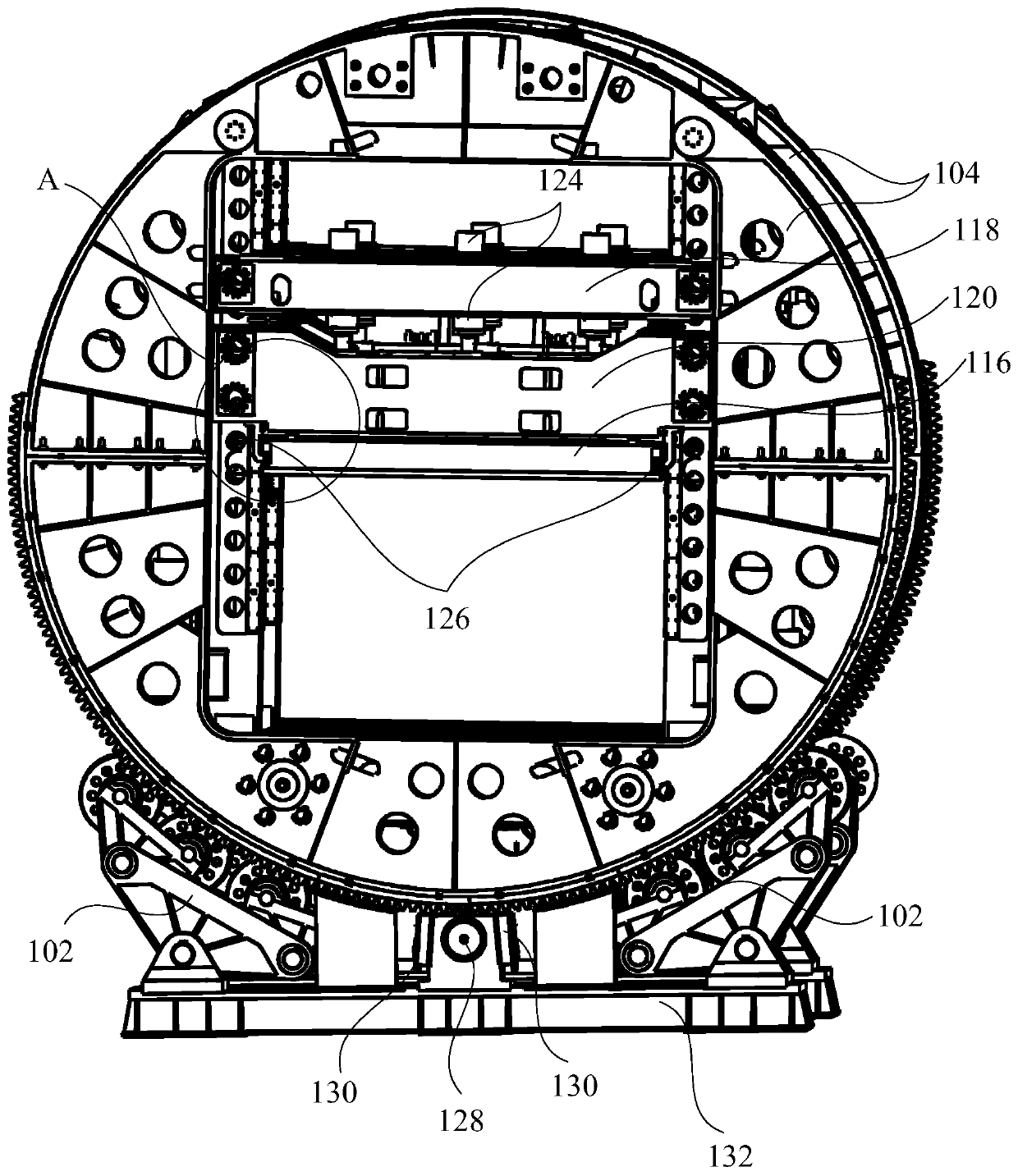

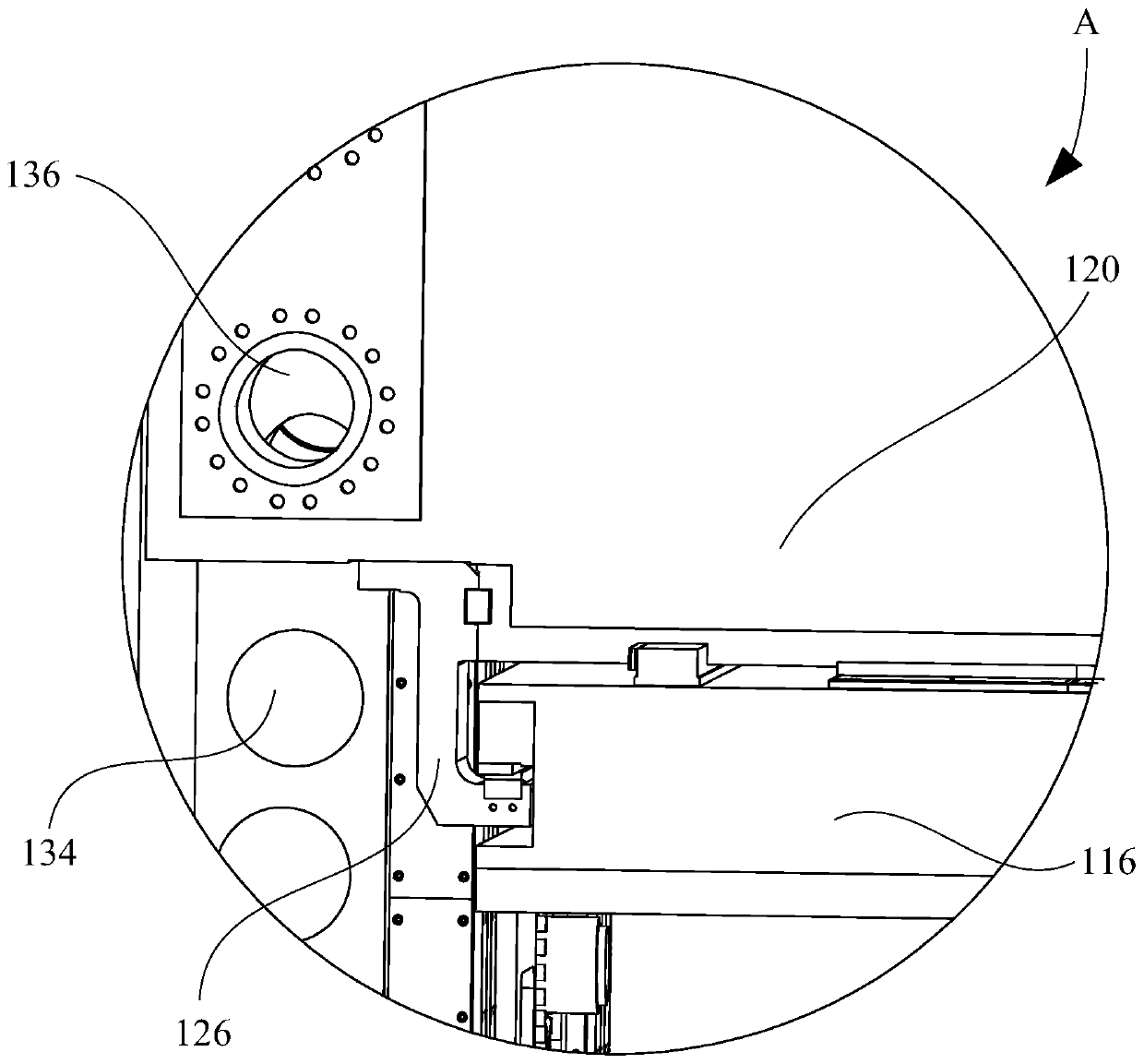

[0038] see Figure 1 to Figure 3 The hydraulic support test device provided by the embodiment of the present invention includes a roller device 102 fixedly arranged on the foundation, a roller disc 104 rotatably installed on the roller device 102, and a main frame arranged on the side of the roller disc 104 106. The main body frame 106 includes a base 108 fixedly connected to the roll pan 104 , a top beam 110 fixedly connected to the roll pan 104 , and a column 112 connected between the base 108 and the top beam 110 . The hydraulic support test device also includes a movable platform 114 that is slidably connected with the column 112, a guide rail 126 that is arranged on the movable platform 114 and is perpendicular to the column 112, and a loading platform 116 that is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com