Connector and connector assembly

A connector component and a connector technology, which are applied in the direction of connections, components of connection devices, electrical components, etc., can solve problems such as large-scale buckle connectors, difficulty in increasing the size of buckle parts and buckle claws 881, etc. Achieve the effect of simple structure and increase the buckle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] Embodiments will be described in detail below with reference to the drawings.

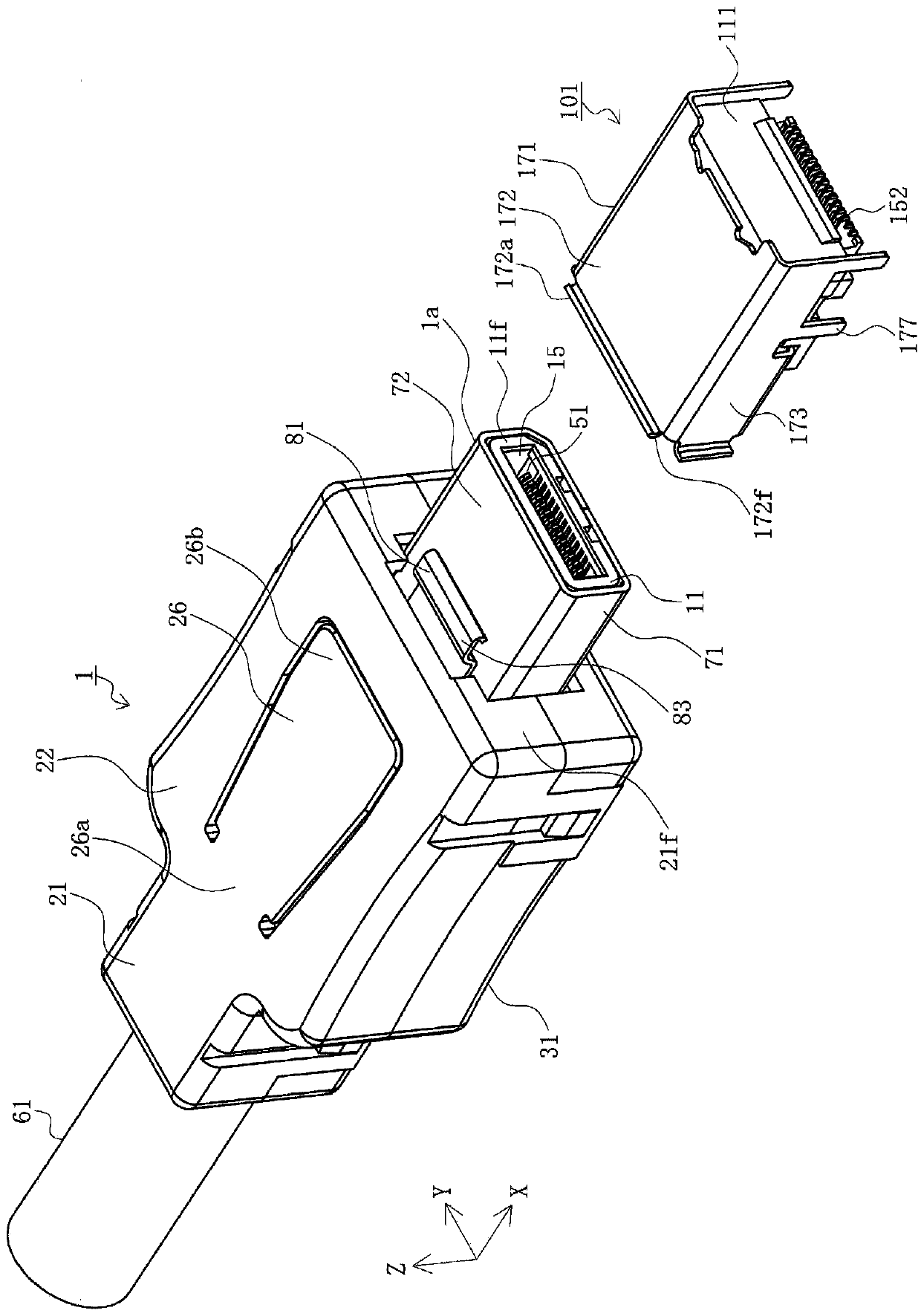

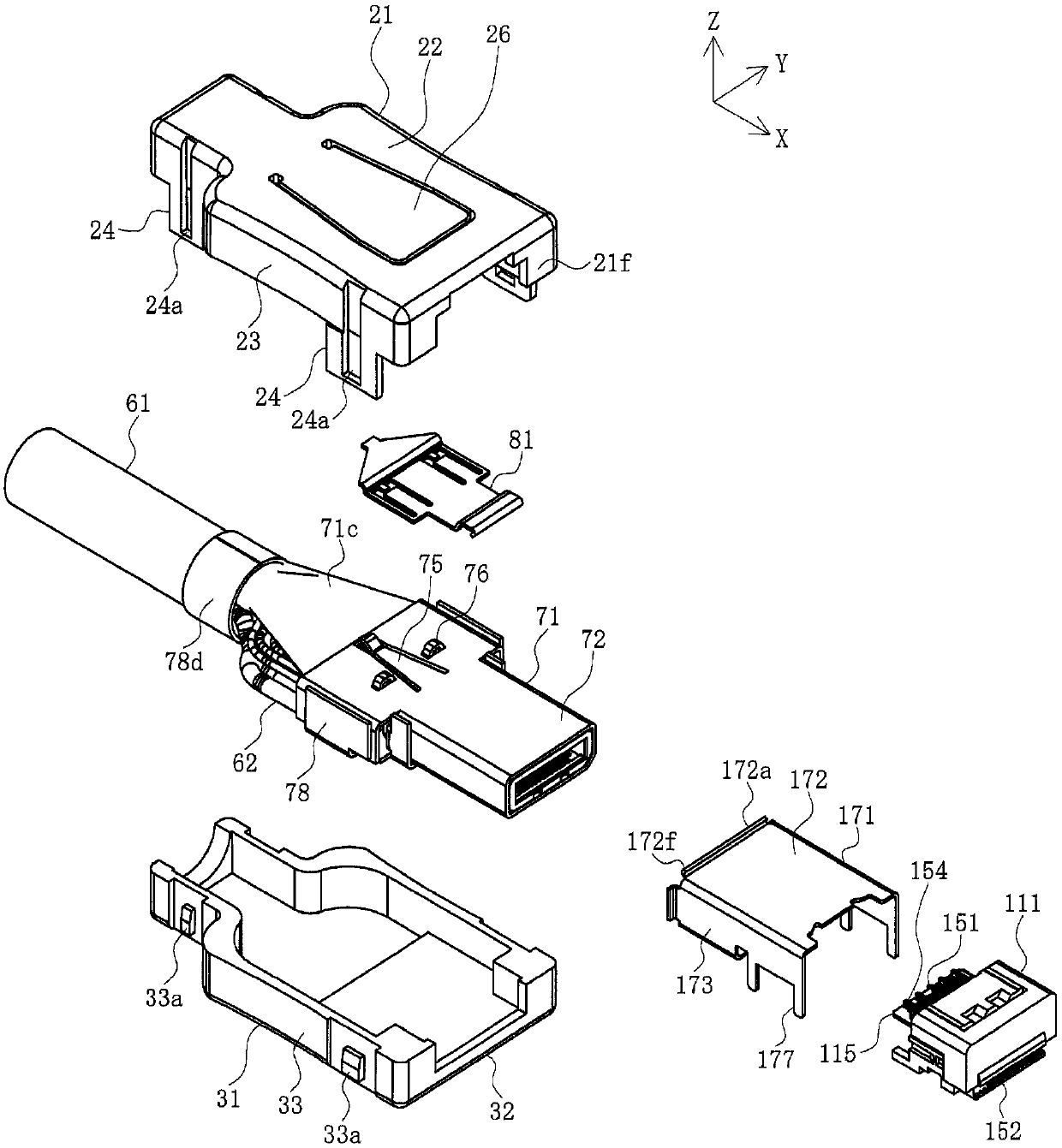

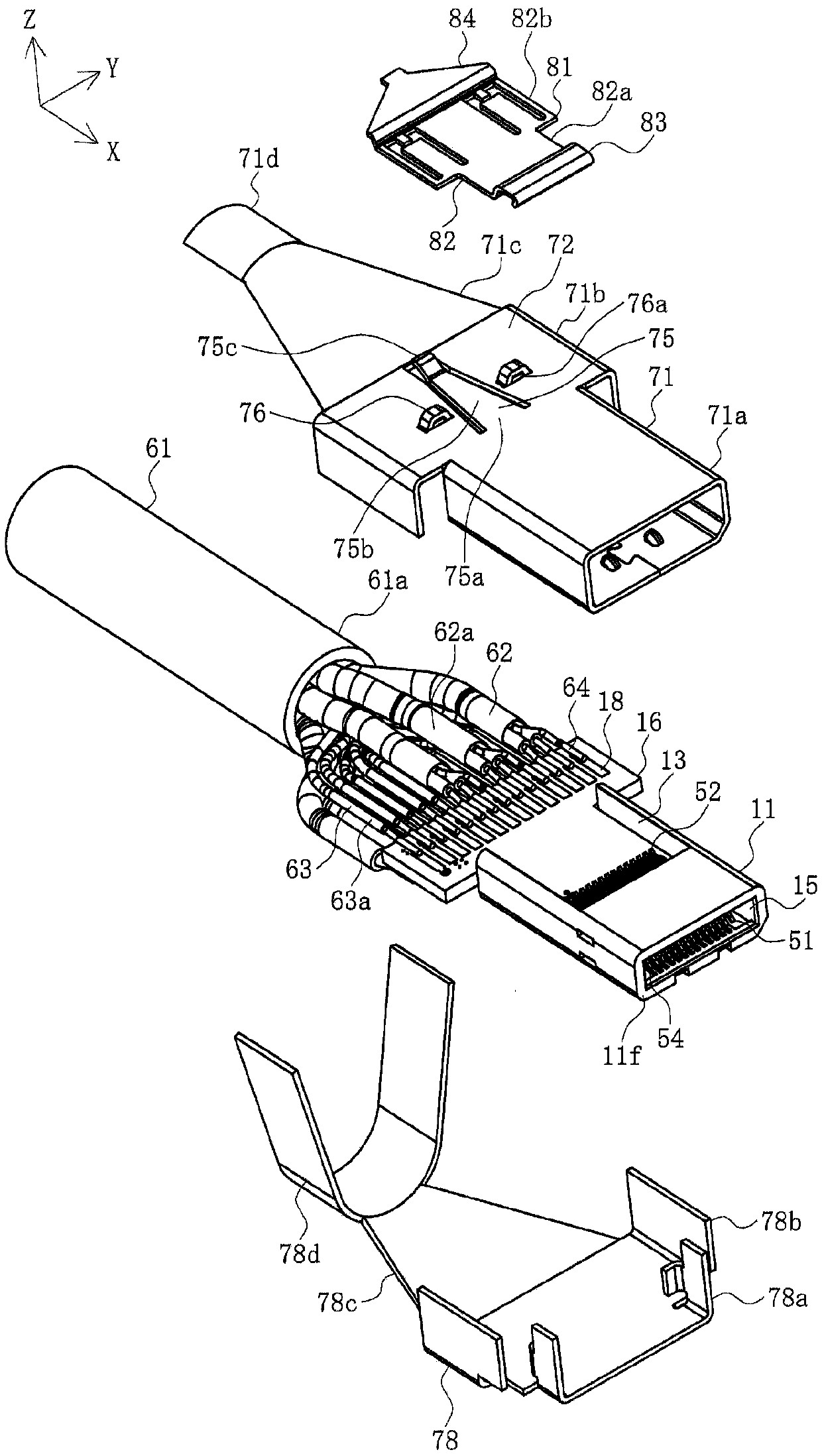

[0114] figure 1 is a perspective view showing a state before the wire connector and the board connector according to the embodiment are fitted. figure 2 is an exploded view of the wire connector and the board connector according to the present embodiment. image 3 is an exploded view of the wire connector according to the present embodiment except for the cover shell portion. Figure 4 is a perspective view seen from above of a part of the wire connector according to the present embodiment. Figure 5 is a perspective view seen from below of the portion of the wire connector according to the present embodiment. Figure 6A , Figure 6B is a perspective view of the buckling part of the wire connector according to this embodiment. Figure 7 It is a perspective view seen from below of the upper side cover case portion of the wire connector according to the present embodiment. Figure 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com