Method for manufacturing shaped components

一种成型构件、构件的技术,应用在制造成型构件领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

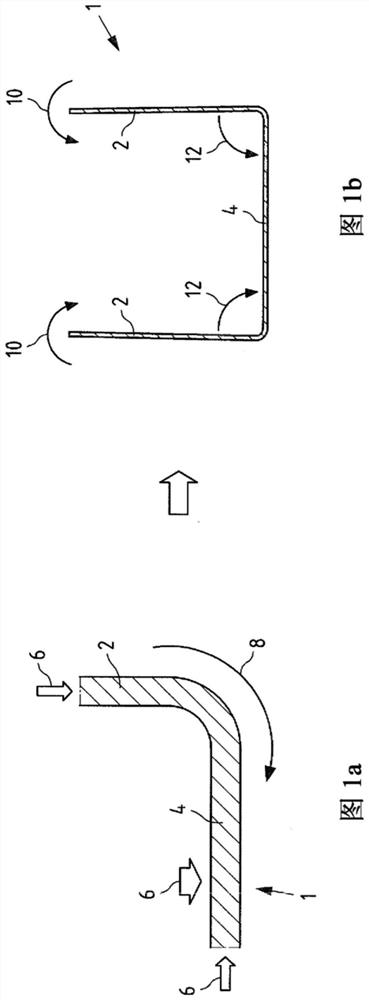

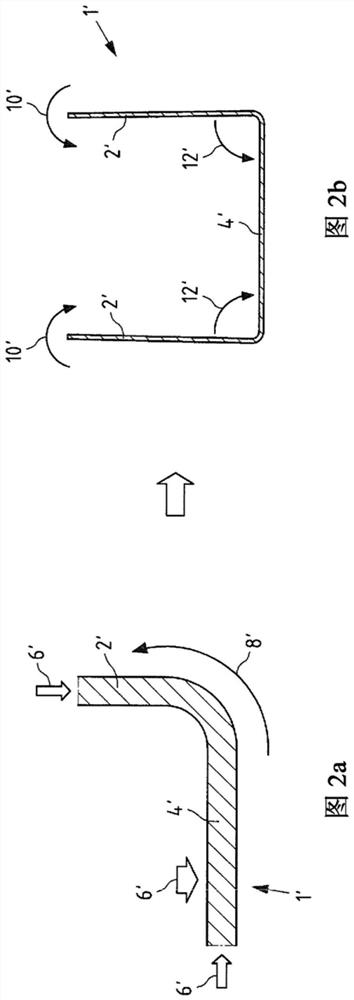

[0042] Figures 1, 2 respectively show schematic cross-sectional views of the side plate area 2, 2' and the bottom area 4, 4' of a component 1, 1' for illustrating an embodiment of the method for a component 1, 1' Effect.

[0043] Component 1 in Figure 1 has a bottom-specific material adaptation in the form of a material addition or upset allowance of +2%, and a side plate-specific material adaptation in the form of a material addition or upset allowance of +3% . As a result of the upsetting indicated by arrow 6 during the alignment process, material flows from the side plate area into the bottom area, as indicated by arrow 8 . have been determined by simulation and in Figure 1b As shown in , this results in a reduction in the side plate opening angle or the distance between the ends of the side plates (arrows 10, 12). As a result, a CAD-accurate bottom radius can be achieved, and the outward springback of the side plate area 2 can be counteracted, thereby improving dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com