Vacuum pressure pouring process for epoxy resins insulation pouring piece of high voltage electric appliance

A technology for epoxy resin and high-voltage electrical appliances, applied in the field of vacuum pressure casting process, can solve the problems of product appearance sink marks and bubbles, reducing reliability, affecting the sealing performance of fully enclosed combined electrical appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

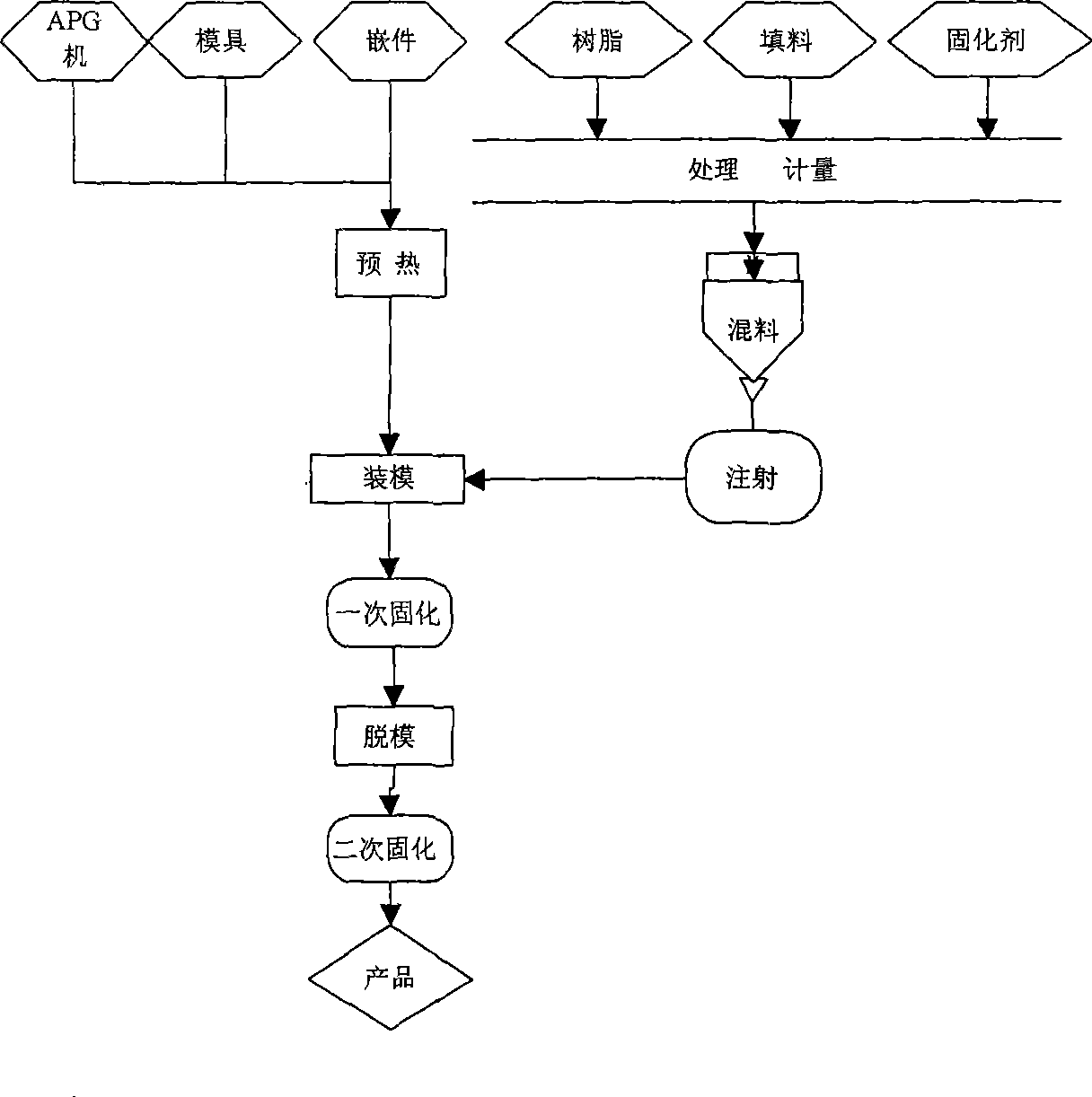

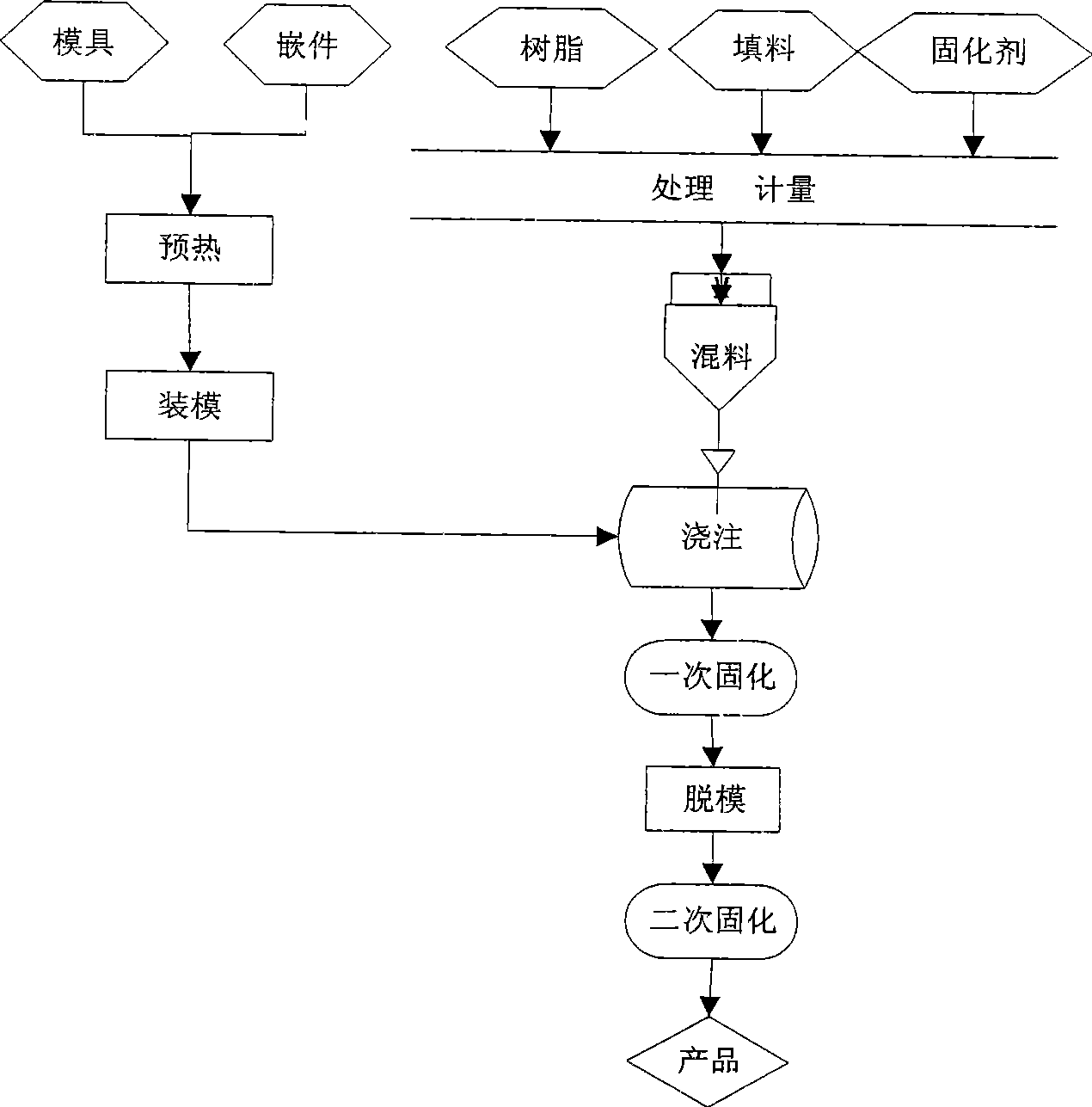

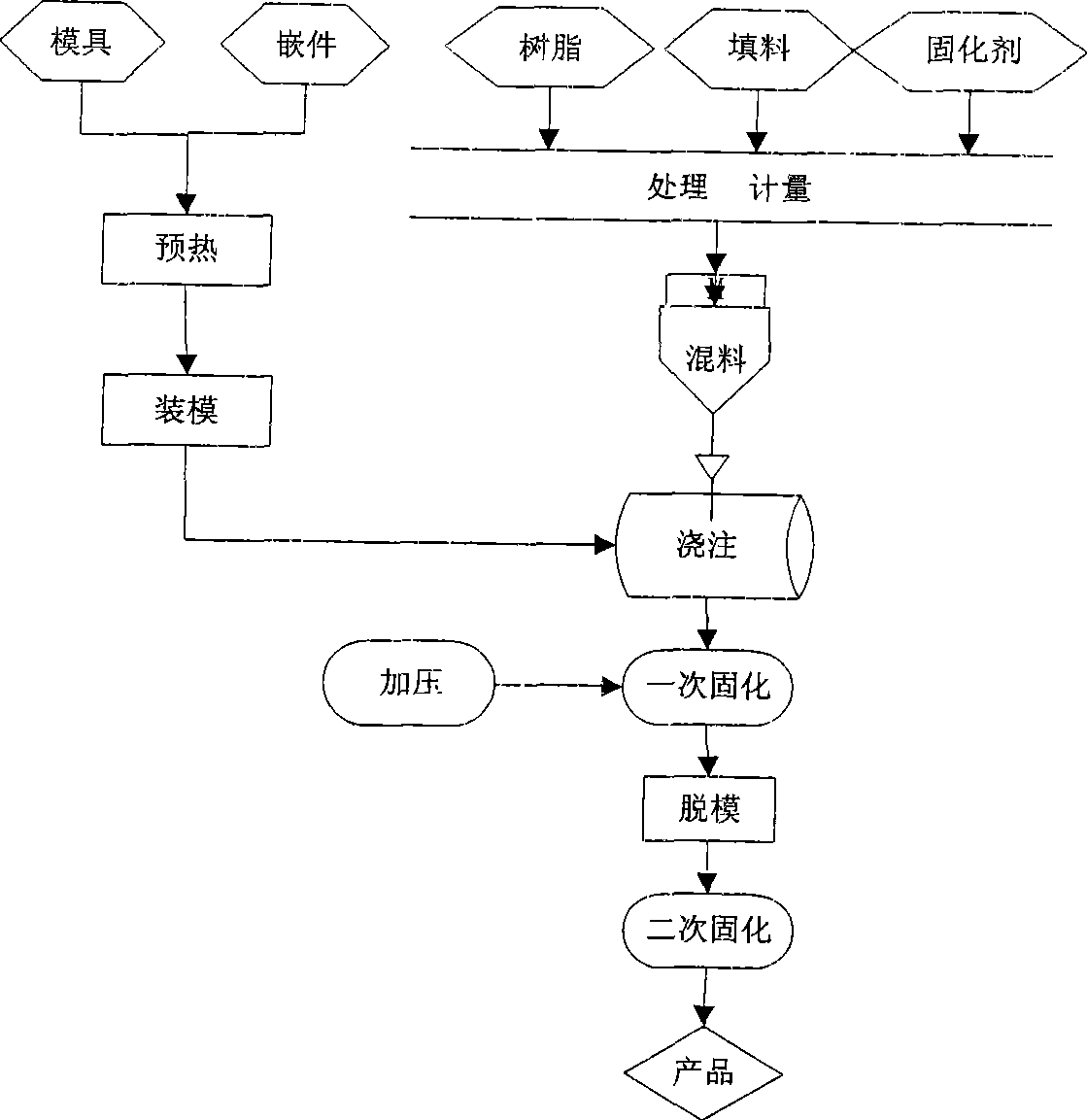

[0029] Such as image 3 Shown is the vacuum pressure casting process of the epoxy resin insulating casting for high-voltage electrical appliances disclosed by the present invention, which includes three processes: mixing, pouring and curing (primary, secondary).

[0030] First, mix epoxy resin, filler, curing agent and other casting materials evenly in a mixing tank at a certain temperature and vacuum. In this step, the selection of specific materials depends on the actual product. The determination of temperature and vacuum degree is the same as the vacuum casting process. It depends on the specific material, the size and shape of the product, etc. This is a known technology, and the general temperature is 110°C -135℃, vacuum degree is 1-10mbar.

[0031] Then, pour the mixed material into the mold placed in the pouring tank at a certain temperature and vacuum. In this step, the determination of temperature and vacuum is the same as the vacuum casting process, depending on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com