Cell coating machine conveying mechanism for suppressing coating bubbles and cell coating method

A technology of conveying mechanism and coating machine, which is applied in the direction of battery assembly machine, non-aqueous electrolyte battery, non-aqueous electrolyte storage battery, etc., which can solve the problems such as elimination or reduction that have not been proposed, and achieve the goal of ensuring the appearance quality, reducing air bubbles, and suppressing air bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

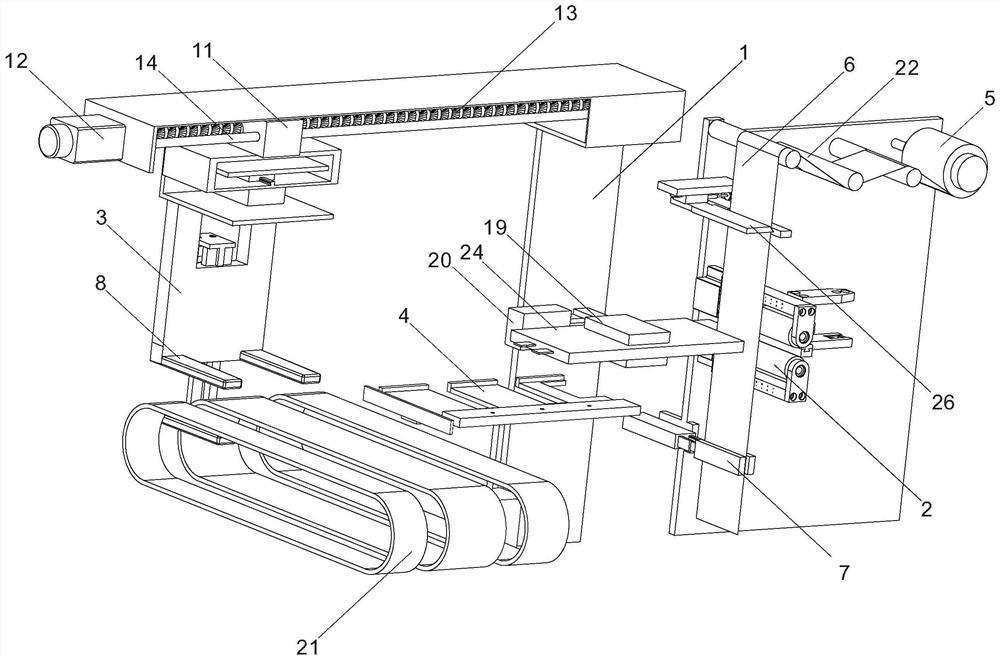

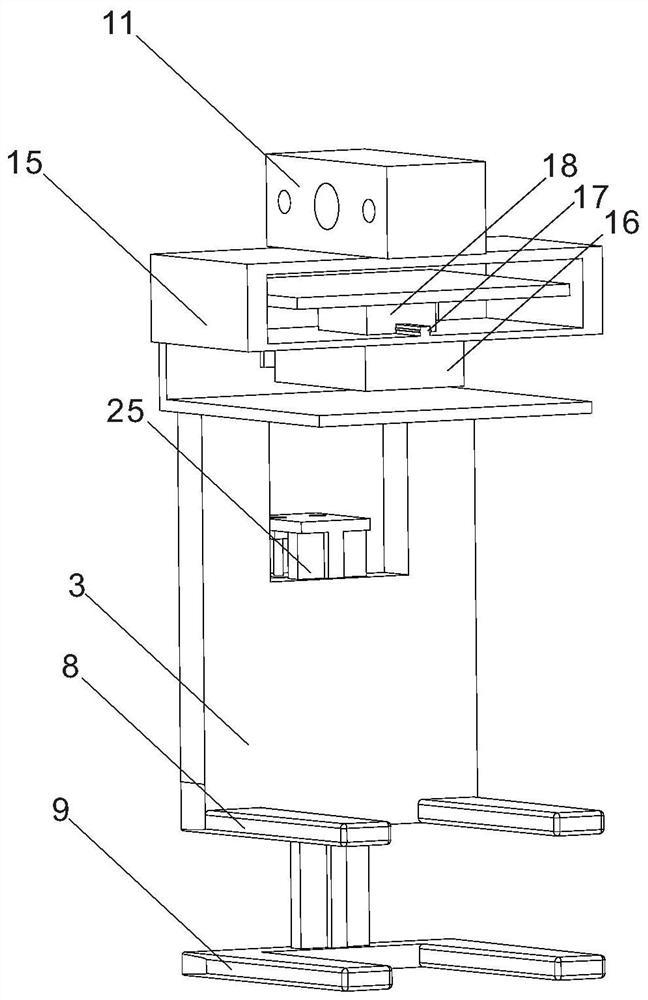

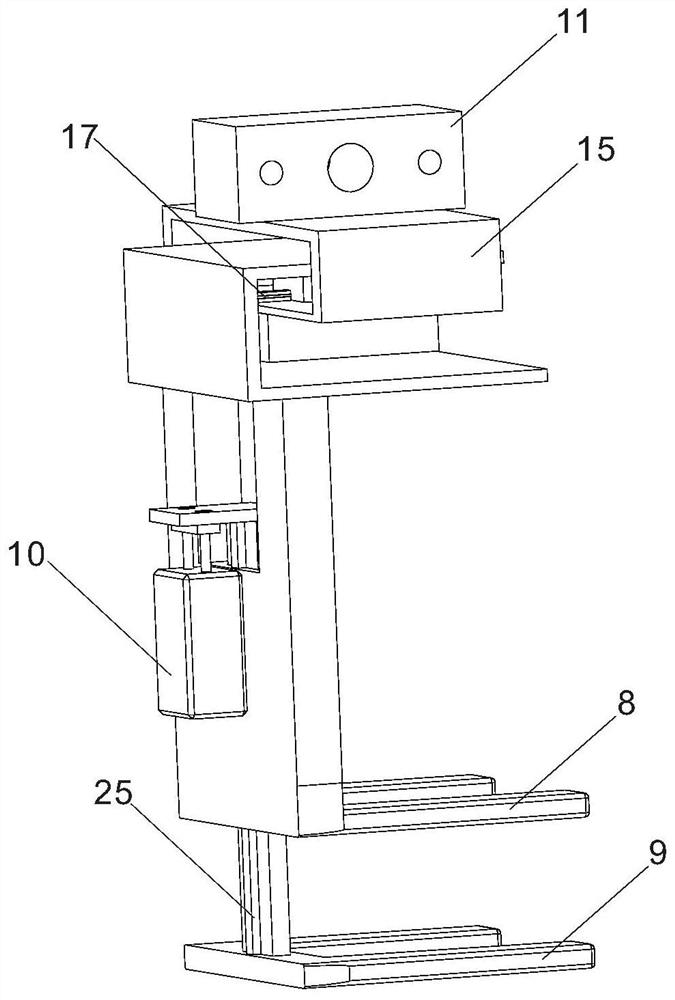

[0027] like figure 1 , figure 2 , image 3 , Figure 4As shown, the conveying mechanism of the cell coating machine that suppresses the bubbles in the coating is set on the frame 1 of the cell coating machine. Roller group, a film roll shaft 5, three film-drawing rollers 22 and a film cutter 26, the film-applying roller group includes a pair of vertically arranged and parallel film-applying rollers 2, and the film-applying roller 2 is made of polyurethane with a Shore hardness of 20° , between the two laminating rollers 2, there is a return tension spring 23, the free end of the PET film 6 on the roll film shaft 5 is clamped on the lifting film clamping finger 7, and the unfolded PET film 6 moves from the positioning platform 4 and the Passes between sets of film rolls. The front end of the cell coating machine inputs the 24 workpieces of the cell that have been plastic-sealed with aluminum-plastic film through the cell conveyor belt. The conveying mechanism of the cell ...

Embodiment 2

[0036] The movable splint driving device 10 is an electric cylinder. Film sticking roller 2 selects the rubber that Shore hardness is 20 ° for use. All the other are with embodiment 1.

Embodiment 3

[0038] Film sticking roller 2 selects the rubber that Shore hardness is 22 ° for use. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com